Introduction

A frame element is formulated to model a straight bar of an arbitrary cross-section, which can deform not only in the axial direction but also in the directions perpendicular to the axis of the bar. The bar is capable of carrying both axial and transverse forces, as well as moments. Therefore, a frame element is seen to possess the properties of both truss and beam elements. In fact, the frame structure can be found in most of our real world structural problems, for there are not many structures that deform and carry loadings purely in axial directions nor purely in transverse directions. The development of FEM equations for beam elements facilitates the development of FEM equations for frame structures in this topic.

The frame element developed is also known in many commercial software packages as the general beam element, or even simply the beam element. Commercial software packages usually offer both pure beam and frame elements, but frame structures are more often used in actual engineering applications. A three-dimensional spatial frame structure can practically take forces and moments of all directions. Hence, it can be considered to be the most general form of element with a one-dimensional geometry.

Frame elements are applicable for the analysis of skeletal type systems of both planar frames (two-dimensional frames) and space frames (three-dimensional frames). A typical three-dimensional frame structure is shown in Figure 6.1. Frame members in a frame structure are joined together by welding so that both forces and moments can be transmitted between members. In this topic, it is assumed that the frame elements have a uniform crosssectional area. If a structure of varying cross-section is to be modelled using the formulation in this topic, then it is advised that the structure is to be divided into smaller elements of different constant cross-sectional area so as to simulate the varying cross-section. Of course, if the variation in cross-section is too severe for accurate approximation, then the equations for a varying cross-sectional area can also be formulated without much difficulty using the same concepts and procedure given in this topic.

Figure 6.1. Example of a space frame structure.

FEM Equations For Planar Frames

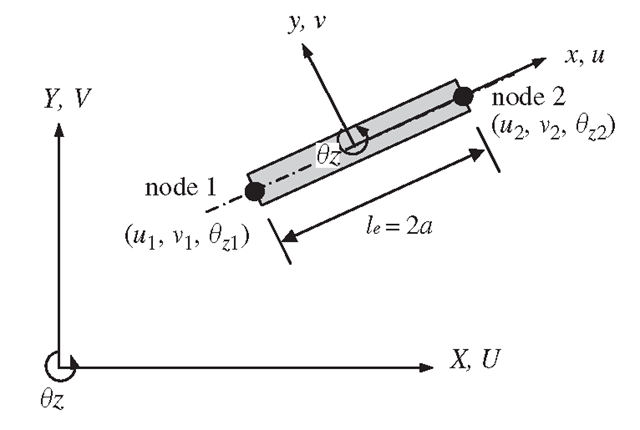

Consider a frame structure whereby the structure is divided into frame elements connected by nodes. Each element is of length le = 2a, and has two nodes at its two ends. The elements and nodes are numbered separately in a convenient manner. In a planar frame element, there are three degrees of freedom (DOFs) at one node in its local coordinate system, as shown in Figure 6.2. They are the axial deformation in the x direction, u; deflection in the y direction, v; and the rotation in the x-y plane and with respect to the z-axis, θζ. Therefore, each element with two nodes will have a total of six DOFs.

Equations in Local Coordinate System

Considering the frame element shown in Figure 6.2 with nodes labelled 1 and 2 at each end of the element, it can be seen that the local x-axis is taken as the axial direction of the element with its origin at the middle of the element. As mentioned, a frame element contains both the properties of the truss element and the beam element. Therefore, the element matrices for a frame element can be simply formulated by combining element matrices for truss and beam elements, without going through the detailed process of formulating shape functions and using the constitutive equations for a frame.

Figure 6.2. Planar frame element and the DOFs.

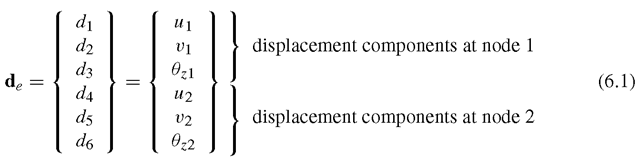

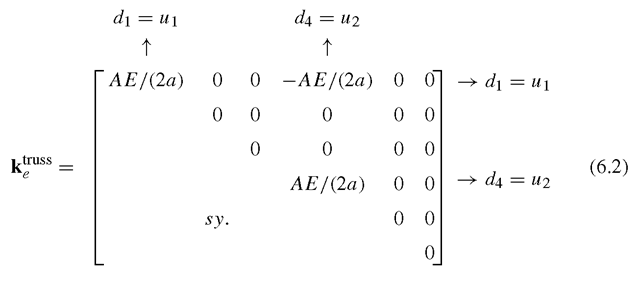

Recall that the truss element has only one degree of freedom at each node (axial deformation), and the beam element has two degrees of freedom at each node (transverse deformation and rotation). Combining these will give the degrees of freedom of a frame element, and the element displacement vector for a frame element can thus be written as

To construct the stiffness matrix, the stiffness matrix for truss elements, Eq. (4.16), is first extended to a 6 x 6 matrix corresponding to the order of the degrees of freedom of the truss element in the element displacement vector in Eq. (6.1):

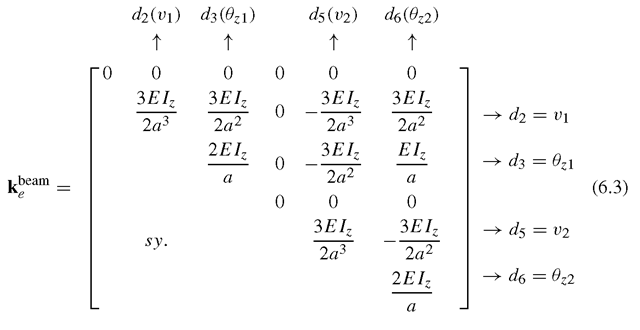

Next, the stiffness matrix for the beam element, Eq. (5.21), is also extended to a 6 x 6 matrix corresponding to the order of the degrees of freedom of the beam element in Eq. (6.1):

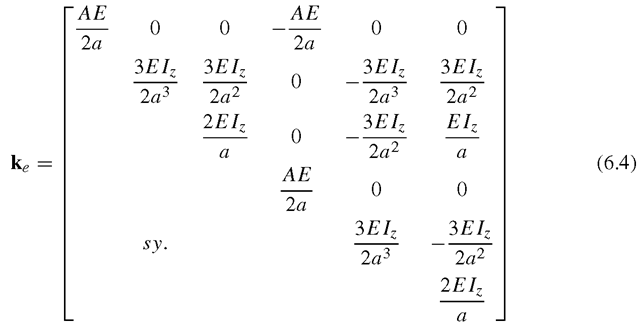

The two matrices in Eqs. (6.2) and (6.3) are now superimposed together to obtain the stiffness matrix for the frame element:

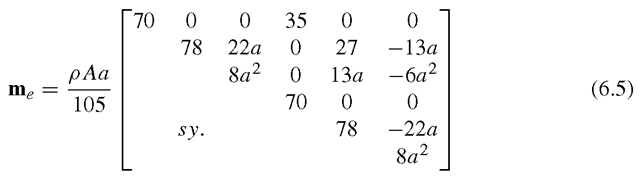

The element mass matrix of the frame element can also be obtained in the same way as the stiffness matrix. The element mass matrices for the truss element and the beam element, Eqs. (4.17) and (5.23), respectively, are extended into 6 x 6 matrices and added together to give the element mass matrix for the frame element:

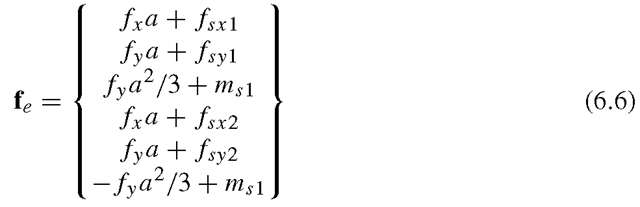

The same simple procedure can be applied to the force vector as well. The element force vectors for the truss and beam elements, Eqs. (4.18) and (5.24), respectively, are extended into 6 x 1 vectors corresponding to their respective DOFs and added together. If the element is loaded by external distributed forces fx and fy along the x-axis; concentrated forces fsx1, fsx2, fsy1 and fsy2; and concentrated moments ms1 and ms2, respectively, at nodes 1 and 2, the total nodal force vector becomes

The final FEM equation will thus have the form of Eq. (3.89) with the element matrices having the forms in Eqs. (6.4) to (6.6).

Equations in Global Coordinate System

The matrices formulated in the previous section are for a particular frame element in a specific orientation. A full frame structure usually comprises numerous frame elements of different orientations joined together. As such, their local coordinate system would vary from one orientation to another. To assemble the element matrices together, all the matrices must first be expressed in a common coordinate system, which is the global coordinate system.

Assume that local nodes 1 and 2 correspond to the global nodes i and j, respectively. The displacement at a local node should have two translational components in the x and y directions and one rotational deformation. They are numbered sequentially by u, v and θζ at each of the two nodes, as shown in Figure 6.3. The displacement at a global node should also have two translational components in the X and Y directions and one rotational deformation. They are numbered sequentially by D3i-2, D3i-I and D3i for the ith node, as shown in Figure 6.3. The same sign convention also applies to node j. The coordinate transformation gives the relationship between the displacement vector de based on the local coordinate system and the displacement vector De for the same element, but based on the global coordinate system:

where

Figure 6.3. Coordinate transformation for 2D frame elements.

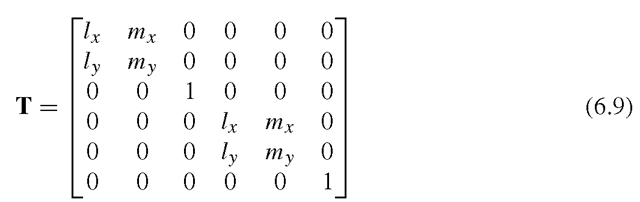

and T is the transformation matrix for the frame element given by

in which

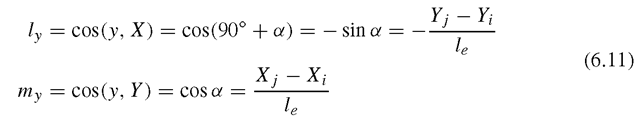

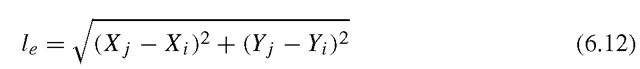

where a is the angle between the x-axis and the X-axis, as shown in Figure 6.3, and

Note that the coordinate transformation in the X-Y plane does not affect the rotational DOF, as its direction is in the z direction (normal to the x-y plane), which still remains the same as the Z direction in the global coordinate system. The length of the element, le, can be calculated by

Equation (6.7) can be easily verified, as it simply says that at node i, u i equals the summation of all the projections of D3i-2 and D3i-1 onto the local x axis, and V1 equals the summation of all the projections of D3i-2 and D3i-1 onto the local y axis. The same can be said at node j. The matrix T for a frame element transforms a 6 x 6 matrix into another 6 x 6 matrix. Using the transformation matrix, T, the matrices for the frame element in the global coordinate system become

Note that there is no change in dimension between the matrices and vectors in the local and global coordinate systems.

FEM Equations For Space Frames

Equations in Local Coordinate System

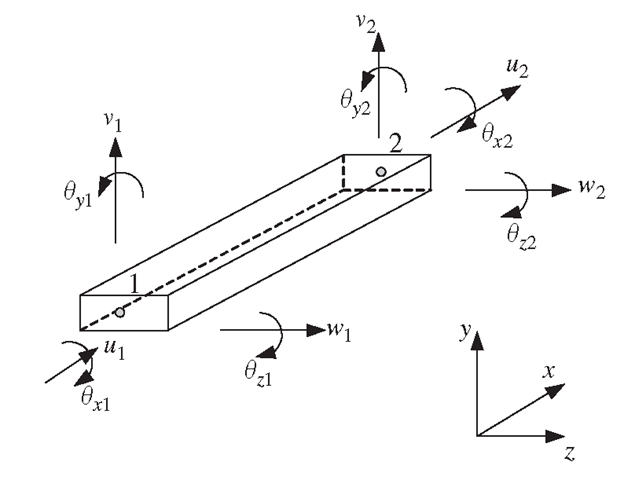

The approach used to develop the two-dimensional frame elements can be used to develop the three-dimensional frame elements as well. The only difference is that there are more DOFs at a node in a 3D frame element than there are in a 2D frame element. There are altogether six DOFs at a node in a 3D frame element: three translational displacements in the x, y and z directions, and three rotations with respect to the x, y and z axes. Therefore, for an element with two nodes, there are altogether twelve DOFs, as shown in Figure 6.4.

Figure 6.4. Frame element in space with twelve DOFs.

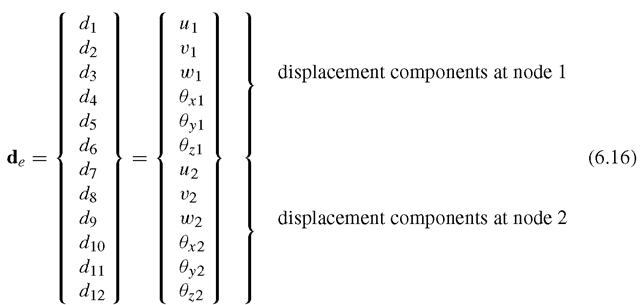

The element displacement vector for a frame element in space can be written as

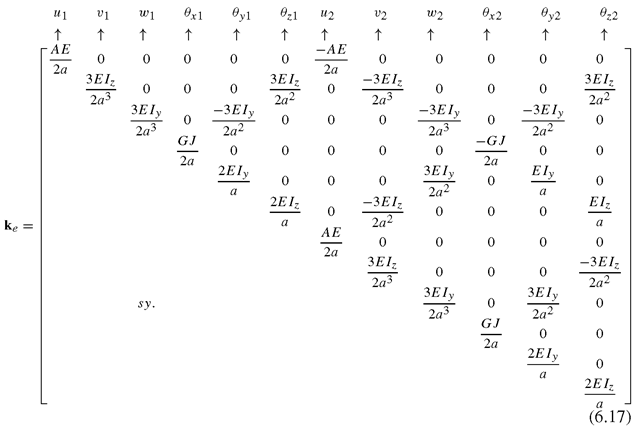

The element matrices can be obtained by a similar process of obtaining the matrices of the truss element in space and that of beam elements, and adding them together. Because of the huge matrices involved, the details will not be shown in this topic, but the stiffness matrix is listed here as follows, and can be easily confirmed simply by inspection:

where Iy and Iz are the second moment of area (or moment of inertia) of the cross-section of the beam with respect to the y and z axes, respectively. Note that the fourth DOF is related to the torsional deformation. The development of a torsional element of a bar is very much the same as that for a truss element. The only difference is that the axial deformation is replaced by the torsional angular deformation, and axial force is replaced by torque. Therefore, in the resultant stiffness matrix, the element tensile stiffness AE/le is replaced by the element torsional stiffness GJ/le, where G is the shear modules and J is the polar moment of inertia of the cross-section of the bar.

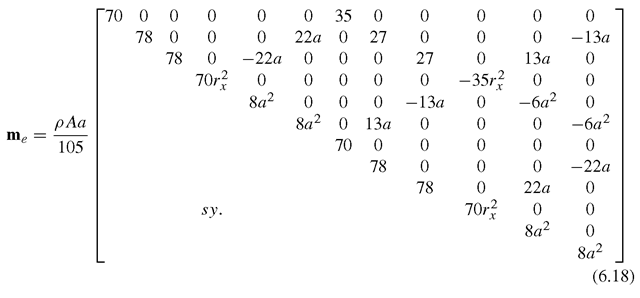

The mass matrix is also shown as follows:

where

in which Ix is the second moment of area (or moment of inertia) of the cross-section of the beam with respect to the x axis.