Solution Process

Let us now try to relate the information provided in the input file with what is formulated in this topic. The first part of the ABAQUS input normally describes the nodes and their coordinates (position). These lines are often called ‘nodal cards1’. The second part of the input file are the so-called ‘element cards’. Information regarding the definition of the elements using nodes is provided. For example, element 1 is formed by nodes 1 and 2. The element cards give the connectivity of the element or the order of the nodal number that forms the element. The connectivity is very important, because a change in the order of the nodal numbers may lead to a breakdown of the computation. The connectivity is also used as the index for the direct assembly of the global matrices (see Example 4.2). This element and nodal information is required for determining the stiffness matrix (Eq. (5.21)) and the mass matrix (Eq. (5.23)).

The property cards define the properties (type of element, cross-sectional property, etc.) of the elements, as well as the material which the element is made of. The cross-section of the element is defined here as it is required for computation of the moment of area about the z-axis, which is in turn used in the stiffness matrix. The material properties defined are also a necessity for the computation of both the stiffness (elastic properties) and mass matrices (density).

The boundary cards (BC cards) define the boundary conditions for the model. In ABAQUS, a node of a general beam element (equivalent to the frame element, to be discussed in the next topic) in the XY plane has three DOFs: translational displacements in the x and y directions (1, 2), and the rotation about the z-axis (6). To model just the transverse displacements and rotation as depicted in the formulation in this topic, the x-displacement DOFs are constrained here. Hence it can be seen from the input file that the DOF ‘1’ is constrained for all nodes. In addition to this, the two nodes at the ends, nodes 1 and 11, also have their ‘2’ and ‘6’ DOFs constrained to simulate clamped ends. Just as in the worked example previously, constraining these DOFs would effectively reduce the dimension of the matrix.

We should usually also have load cards. Because this case study is an eigenvalue analysis, there are no external loadings, and hence there is no need to define any loadings in the input file.

The control cards are used to control the analysis, such as defining the type of analysis required. ABAQUS uses the subspace iteration scheme by default to evaluate the eigenvalues of the equation of motion. This method is a very effective method of determining a number of lowest eigenvalues and corresponding eigenvectors for a very large system of several thousand DOFs. The procedure is as follows:

(i) To determine the n lowest eigenvalues and eigenvectors, select a starting matrix X1 having m (>n) columns.

(iii) Calculate![]() where the dimension of

where the dimension of

(iv) Solve the reduced eigenvalue problem![]() for m eigenvalues, which are the diagonal terms of the diagonal matrix

for m eigenvalues, which are the diagonal terms of the diagonal matrix![]() and for eigenvectors

and for eigenvectors ![]()

(v) Calculate the improved approximation to the eigenvectors of the original system using

(vi) Repeat the process until the eigenvalues and eigenvectors converge to the lowest eigenvectors to desired accuracy.

By specifying the line ‘*FREQUENCY’ in the analysis step, ABAQUS will carry out a similar algorithm as that briefly explained above. The line after the ‘*FREQUENCY’ contains some data which ABAQUS uses to aid the procedure. The first entry refers to the number of eigenvalues required (in this case, 3). The second refers to the maximum frequency of interest. This will limit the frequency range, and therefore anything beyond this frequency will not be calculated. In this case, no maximum frequency range will be specified. The third is to specify shift points, which is used to ensure that the stiffness matrix is not singular. Here, again, it is left blank since it is not necessary. The fourth is the number of columns of the starting matrix X1 to be used. It is left blank again, and thus ABAQUS will use its default setting. The last entry is the number of iterations, which in this case is 30.

Output control cards are used for selecting the data that needs to be output. This is very useful for large scale computation that produces huge data files; one needs to limit the output to what is really needed.

Once the input file is created, one can then invoke ABAQUS to execute the analysis, and the results will be written into an output file that can be read by the post-processor.

Result and Discussion

Using the above input file, an analysis to calculate the eigenvalues, and hence the natural resonant frequencies of the bridge structure, is carried out using ABAQUS. Other than the 10-element mesh as shown in Figure 5.6, which is also depicted in the input file, a simple convergence test is carried out. Hence, there are similar uniform meshes using 20, 40 and 60 elements. All the frequencies obtained are given in Table 5.3. Because the clamped-clamped beam structure is a simple problem, it is possible to evaluate the natural frequencies analytically. The results obtained from analytical calculations are also shown in Table 5.3 for comparison.

Table 5.3. Resonant frequencies of bridge using FEA and analytical calculations

|

Number of two-node beam elements |

Natural frequency (Hz) |

|

|

|

Mode 1 |

Mode 2 |

Mode 3 |

|

|

10 |

4.4058 x 105 |

1 .2148 x 106 |

2.3832 x 106 |

|

20 |

4.4057 x 105 |

1 .2145 x 106 |

2.3809 x 106 |

|

40 |

4.4056 x 105 |

1 .2144 x 106 |

2.3808 x 106 |

|

60 |

4.4056 x 105 |

1 .2144 x 106 |

2.3808 x 106 |

|

Analytical calculations |

4.4051 x 105 |

1.2143 x 106 |

2.3805 x 106 |

From the table, it can be seen that the finite element results give very good approximations as compared to the analytical results. Even with just 10 elements, the error of mode 1 frequency is about 0.016% from the analytical calculations. It can also be seen that as the number of elements increases, the finite element results gets closer and closer to the analytical calculations, and converges such that the results obtained for 40 and 60 elements show no difference up to the fourth decimal place. What this implies is that in finite element analyses, the finer the mesh or the greater the number of elements used, the more accurate the results. However, using more elements will use up more computer resources, and it will take a longer time to execute. Hence, it is advised to use the minimum number of elements which give the results of desired accuracy.

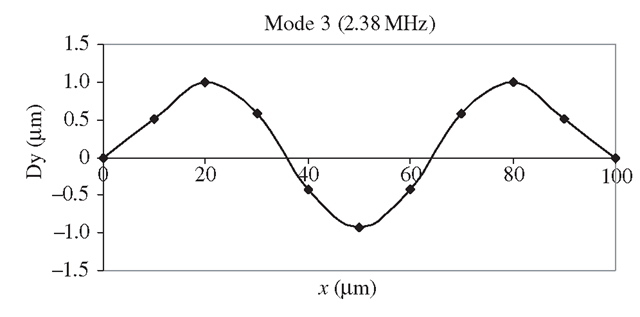

Other than the resonant frequencies, the mode shapes can also be obtained. Mode shapes can be considered to be the way in which the structure vibrates at a particular natural frequency. It corresponds to the eigenvector of the finite element equation, just like the resonant frequencies corresponds to the eigenvalues of the finite element equation. Mode shapes can be important in some applications, where the points of zero displacements, like the centre of the beam in Figure 5.8, need to be identified for the installation of devices which should not undergo huge vibration.

The data for constructing the mode shape for each eigenvalue or natural frequency can be obtained from the displacement output for that natural frequency. Figures 5.7 to Figure 5.9 show the mode shapes obtained by plotting the displacement components using 10 elements. The figures show how the clamped-clamped beam will vibrate at the natural frequencies. Note that the output data usually consists of only the output at the nodes, and these are then used by the post-processor or any graph plotting applications to form a smooth curve. Most post-processors thus contain curve fitting functions to properly plot the curves using the data values.

This simple case study points out some of the basic requirements needed in a finite element analysis. Like ABAQUS, most finite element software works on the same finite element principles. All that is needed is just to provide the necessary information for the software to use the necessary type of elements, and hence the shape functions; to build up the necessary element matrices; followed by the assembly of all the elements to form the global matrices; and finally, to solve the finite element equations.

Figure 5.9. Mode 3 using 10 elements at 2.4276 x 106 Hz.