Introduction

The squirrel cage induction motor is probably the most widely used motor in industry today. Traditional applications for AC induction motors include fans and pumps. The AC induction motor has been widely accepted in many demanding industrial applications, compared with the DC motor, because less maintenance is required. It is quite common to find AC motors in applications such as compressors, machine tools, conveyors,

mixers, crushers, ski lifts, and extruders. With its efficient operation and energy savings characteristics, the AC induction motor will increase in prominence throughout the next several decades.

The basic principles of operation of any manufacturer’s motor is essentially the same. Specific designs may differ, such as the air gap between the rotating parts, voltage insulation strength, and resistance to high-voltage spikes. However, the main parts in an induction motor are all the same.

It should be noted here that in the world of AC motors, there are basically two languages: NEMA (National Electrical Manufacturers Association) in North America, and IEC (International Electrotechnical Commission) in most of the rest of the world. Until recently, there was little need to be aware of the differences, both subtle and obvious. However, that is all changing as the motor market becomes more global. This trend gained additional fuel in 1992 when the economies of the European Common Market countries became one.

Later in this section, NEMA versus IEC motor ratings will be explored. More companies are shipping their electrical products overseas, and vice versa. In the not-so-distant future, it will be difficult to not come in contact with an IEC-rated motor. Therefore, a review of the comparisons will be useful. In addition, because of industry’s wide use of three-phase induction motors, the focus of this section will be on that motor type. However, several other common three-phase motor types will also be explored.

All AC motors can be classified into single-phase and polyphase motors (poly meaning many-phase, or three-phase). Because polyphase motors are the most commonly used in industrial applications, we will take a closer look at the construction of these units. Keep in mind that there are also single-phase AC motors in use for applications such as small appliances, residential fans, furnaces, and many other low-horsepower applications.

For industrial applications, however, mainly three-phase induction motors are used. The main advantage of using three-phase motors is efficiency. Three-phase motors are much simpler in construction than other types and require less maintenance. A more powerful motor can be built into a smaller frame compared with a single-phase motor. The three-phase motor will operate at a higher efficiency compared with the single-phase motor.

There are several types of polyphase motors: induction, wound rotor, and synchronous. The most common type of motor in this group is the squirrel cage induction motor. This motor type will be the basis for understanding the general AC motor principles.

AC Induction Motor

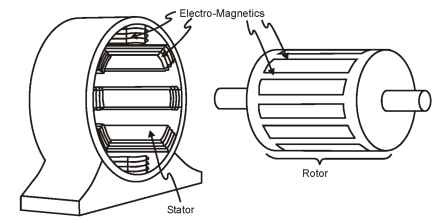

The main parts in an AC induction motor is the rotor (rotating element) and the stator (stationary element that generates the magnetic flux). The

rotor construction looks like a squirrel cage, hence the traditional name: squirrel cage induction motor. Figure 3-23 indicates the rotor construction.

Figure 3-23. Squirrel cage induction motor rotor

The squirrel cage motor is the simplest to manufacture and the easiest to maintain. The operation of the squirrel cage motor is simple. The three-phase current produces a rotating magnetic field in the stator. This rotating magnetic field causes a magnetic field to be set up in the rotor also. The attraction and repulsion between these two magnetic fields causes the rotor to turn. This concept can be seen in Figures 3-24 and 3-25

Figure 3-24. Rotor and stator

The squirrel cage motor is a constant-speed motor with either a normal or high starting torque. These characteristics fulfill the requirements of the majority of industrial applications.

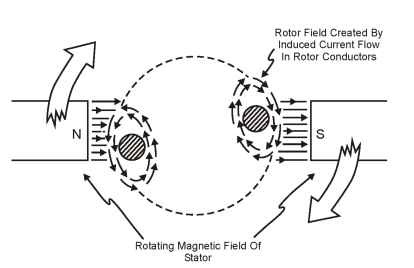

The concept of the rotating magnetic field is shown in Figure 3-26. This figure shows the relationship of the three-phases versus pole magnetic fields. Each magnetic pole pair is wound in such a way that allows the sta-

Figure 3-25. End view of two rotor segments (magnetic interaction with stator)

tor magnetic field to “rotate.” The stator of the motor consists of groups of coils wound on a core, which are enclosed by a frame. The simple two-pole stator shown in Figure 3-26 has three coils in each pole group. (A two-pole motor would have two poles x three phases = six physical poles.) Each coil in a pole group is connected to one phase of the three-phase power source. One characteristic of three-phase power is that the phase current reaches maximum value at different time intervals. Figure 3-26 also indicates the relationship between maximum and minimum values.

Figure 3-26. Basic two-pole stator

For the sake of example, our focus will be an instant in time when the current is almost at maximum in the “A” coils. (Use the upper left corner of Figure 3-25.) The magnetic fields of these coils will also be at almost maximum value. At this same instant, the currents of phase “B” are at zero and phase “C” currents are slightly more than “A.”

At a later instant in time, the current in the “B” coils is close to maximum with consequent maximizing of the magnetic field of the “B” coils. At this same instant, the field of the “C” phase is slightly less than maximum. The “A” coil fields are at zero value.

This same process repeats as the magnetic field of each of the phases reaches maximum, all at different times (different degrees of magnetic field rotation). The maximum field thus sequentially repeats at “A,” “C,” and “B” continuously around the stator and essentially defines a rotating magnetic field.

The coils of the stator are wound such that they are diametrically opposite coils. This means that they carry the same phase current but are connected so their magnetic fields are of opposite polarity. Again, the motor shown in Figure 3-26 would be a configuration of a two-pole winding.

Magnetic Field (Rotor)

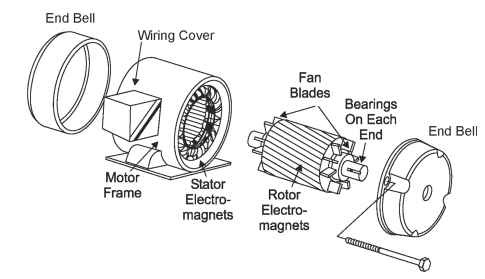

The rotor is the rotating part of the motor. The rotor consists of copper or aluminum bars, connected together at the ends with end rings. Refer to Figure 3-27.

Figure 3-27. Induction motor rotor construction

The inside of the rotor is filled with many individual disks of steel, called laminations. The revolving field set up by the stator currents, cut the squirrel cage conducting aluminum bars of the rotor. This causes voltage in these bars, called induced voltage. This voltage causes current to flow in the aluminum bars. The current sets up a magnetic field around the bars with corresponding north and south poles in the rotor. Torque is produced from

the attraction and repulsion between these poles and the poles of the revolving stator field.

Figure 3-28 shows the assembly of the parts into a complete induction motor unit.

Figure 3-28. Induction motor construction

Eddy Current Generation

The rotating stator magnetic field and induced voltage in the rotor bars also causes voltage in the stator and rotor cores. The voltage in these cores cause small circulating currents to flow. These currents, called eddy currents, serve no useful purpose and result only in wasted power. To reduce these currents, the stator and rotor cores are constructed with laminations. (discussed in the previous section). These laminations are coated with insulating varnish and then welded together to form the core. This type of core substantially reduces eddy current losses, but it does not eliminate them entirely.

Induction Motor Design

Engineers can design motors for almost any application by changing the design of the squirrel cage rotor and stator coils. Characteristics such as speed, torque, and voltage are just a few of the features controlled by the designer.

To standardize certain motor features, the National Electrical Manufacturers Association (NEMA) has established standards for a number of motor features. The following section contains many of the features that will be helpful in selecting the right motor for a specific application.

Control of Speed, Torque, and Horsepower

Control of Speed

The speed of a squirrel cage motor depends on the frequency and the number of poles for which the motor is wound. The higher the frequency, the faster the motor operates. The more poles the motor has, the slower it operates. The smallest number of poles ever used in a squirrel cage motor is two. A two-pole 60-Hz motor will run at approximately 3600 rpm. As soon will be seen, the motor will always operate at a speed less than 3600 rpm.

To find the approximate speed of any squirrel cage motor, the formula for synchronous speed can be used, which is actually the speed of the rotating magnetic field:

![]()

N = synchronous speed (rpm)

F = frequency of the power supply (Hertz)

P = number of stator poles

Squirrel cage induction motors are wound for the synchronous speeds found in Table 3-1.

| No. of poles | Sync. speed (at 60 Hz) | Sync. speed (at 50 Hz) |

| 2 | 3600 | 3000 |

| 4 | 1800 | 1500 |

| 6 | 1200 | 1000 |

| CO | 900 | 750 |

| 10 | 720 | 600 |

| 12 | 600 | 500 |

Table 3-1. Motor synchronous speeds vs. number of poles

Most standard induction motors (NEMA 143T through 445T frame sizes) are wound with a maximum of eight poles.

The actual speed of the motor shaft is somewhat less than synchronous speed. This difference between the synchronous and actual speeds is defined as slip. If the squirrel cage rotor rotated as fast as the stator field, the rotor bars would be standing still with respect to the rotating magnetic field. No voltage would be induced in the rotor bars, and no magnetic flux would be cut by the rotor bars. The result would be no current set up to produce torque. Since no torque is produced, the rotor will slow down until sufficient current is induced to develop torque. When torque is developed, the rotor will accelerate to a constant speed. Figure 3-29 is a graphical representation of slip.

Figure 3-29. Slip in an induction motor

To summarize: There must be a difference between the rotating magnetic stator field and the actual rotor bars’ position. This allows the rotor bars to cut through the stator magnetic fields and create a magnetic field in the rotor. The interaction of the stator and rotor magnetic fields produce the attraction needed to develop torque.

When the load on the motor increases, the rotor speed decreases. Then the rotating field cuts the rotor bars at a faster rate than before. This has the effect of increasing the current in the rotor bars and increasing the magnetic pole strength of the rotor. Basically, as the load increases, so does the torque output.

Slip is usually expressed as a percentage and can easily be calculated using the following formula:

![]()

Squirrel cage motors are built with the slip ranging from about 3-20%. Motors with a slip of 5% or higher are used for hard-to-start applications. A motor with a slip of 5% or less is called a normal slip motor. A normal slip motor is often referred to as a constant speed motor because the speed changes very little with variations in load.

In specifying the speed of the motor on the nameplate, most motor manufacturers use the actual speed of the motor at rated load. The term used is base speed. Base speed is a speed somewhat lower than the synchronous

speed. It is defined as the actual rotor speed at rated voltage, rated hertz, and rated load.

Direction of Rotation

The direction of rotation of a squirrel cage induction motor depends on the motor connection to the power lines. Rotation can easily be reversed by interchanging any two input leads.

Control of Torque and Horsepower

As discussed earlier, horsepower takes into account the speed at which the shaft rotates. It takes more horsepower to rotate the shaft fast, compared with rotating it slowly. Note: Horsepower is a rate of doing work.

By definition, 1 HP equals 33,000 ft-lb per minute. In other words, lifting a 33,000-pound weight 1 foot, in 1 minute would take 1 HP.

By using the familiar formula below, we can determine the horsepower developed by an AC induction motor.

T = torque in lb-ft N = speed in rpm

For example, a motor shaft turns at 5 rpm and develops 3 lb-ft of torque. By inserting the known information into the formula, we calculate that the motor develops approximately 0.003 HP (3 x 5 -f 5252 = .0028). As the formula shows, horsepower is directly related to the speed of motor shaft. If the shaft turns twice as fast (10 rpm), the motor will develop almost .006 HP, twice as much.

We can see the general rules of thumb for torque developed versus speed by reviewing Table 3-2.

Torque developed will vary slightly on lower HP and rpm motors or non-standard motors.

As seen in Table 3-2, at higher synchronous speeds, the induction motor develops less torque compared with lower speeds. We can also see that the higher the number of poles, the larger the amount of torque developed.

| No. of poles | Sync. speed (at 60 Hz) | Torque developed per HP |

| 2 | 3600 | 1.5 lb-ft |

| 4 | 1800 | 3 lb-ft |

| 6 | 1200 | 4.5 lb-ft |

| 8 | 900 | 6 lb-ft |

| 10 | 720 | 7.5 lb-ft |

| 12 | 600 | 8.75 lb-ft |

Table 3-2. AC induction motor—speed vs. torque developed

Basically, more poles mean stronger magnetic fields that will be produced. With more magnetic flux interacting with rotor flux, a stronger twisting motion will result, thereby developing more torque.

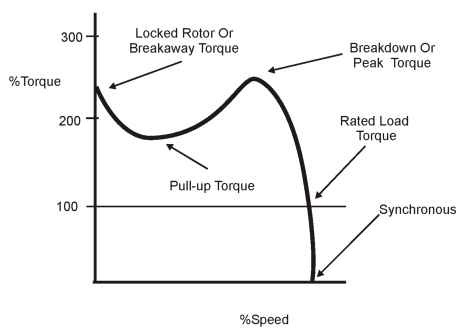

Regarding the issue of motor torque, there are several areas on the standard speed/torque curve that should be reviewed. An induction motor is built to supply this extra torque needed to start the load. The speed torque curve for a typical induction motor is seen in Figure 3-30.

Figure 3-30. Speed/torque curve for a NEMA design B motor

Figure 3-30 shows the starting torque to be about 250% of the rated-load torque.

Peak (Breakdown) Torque

Occasionally a sudden overload will be placed on a motor. To keep the motor from stalling every time an overload occurs, motors have what is called a breakdown torque. The breakdown torque point is much higher than the rated load torque point. For this reason, it takes quite an overload to stall the motor. The speed/torque curve shown in Figure 3-30 indicates the breakdown torque for a typical induction motor to be about 270% of the rated load torque.

Operating a motor overloaded for an extended period of time will cause an excessive heat buildup in the motor and may eventually burn up the motor windings.

The NEMA definitions and ratings for an induction motor’s characteristic torque is given later in this topic.

Locked Rotor Torque (Starting or Breakaway Torque)

The locked rotor torque of a motor is the minimum torque, which it will develop at rest for all angular positions of the rotor. This capability is true with rated voltage and frequency applied.

Pull-Up Torque

The pull-up torque of a motor is the minimum torque developed by the motor when accelerating from rest to the breakdown torque point. For motors that do not have a definite breakdown torque, the pull-up torque is the minimum torque developed up to rated speed.

Peak (Breakdown) Torque

The breakdown torque of a motor is the maximum torque that it will develop. This capability is true with rated voltage and frequency applied, without an abrupt drop in speed.

Rated Load Torque

The rated load torque of a motor is the torque necessary to produce the motor’s rated horsepower at rated-load speed. (Note: Rated load speed is normally considered base speed. Base speed means actual rotor speed when rated voltage, frequency, and load are applied to the motor.)

The above torque designations are all very important to the motor designer. Essentially, motors can be designed with emphasis on one or more of the above torque characteristics to produce motors for various applications. An improvement in one of these torque characteristics may adversely affect some other motor characteristic.

Enclosure Types and Cooling

Motors are often exposed to damaging atmospheres such as excessive moisture, steam, salt air, abrasive or conducting dust, lint, chemical fumes, and combustible or explosive dust or gases. To protect motors, a certain enclosure or encapsulated windings and special bearing protection may be required.

Motors exposed to the following conditions may require special mountings or protection: damaging mechanical or electrical loading such as unbalanced voltage conditions, abnormal shock or vibration, torsional impact loads, excessive thrust, or overhung loads.

Many types of enclosures are available. A few of the most common types are listed here, many of which are the same designations as for DC motors. It is strongly recommended that personnel actively involved with applying induction motors be familiar with, and adhere to, the contents of NEMA MG2 (“Safety Standard for Construction and Guide for Selection, Installation and Use of Electric motors and Generators”).

Open Motor

The open motor enclosure type has ventilation openings that permit passage of external cooling air over and around the windings.

Open Drip-proof Motor

The open drip-proof (ODP) enclosure type is constructed so that drops of liquid or solids falling on the machine from a vertical direction cannot enter the machine. (This vertical direction is not at an angle greater than 15°.)

Guarded Motor

(This could be abbreviated DPFG—drip-proof fully guarded.) The guarded enclosure type has all ventilation openings limited to specified sizes and shapes. This enclosure prevents insertion of fingers or rods and limits accidental contact with rotating or electrical parts.

Splash-proof Motor

The splash-proof enclosure type is so constructed that drops of liquid or solid particles falling on the motor cannot enter. (These liquid or solid particles can be in a straight line or at any angle not greater than 100° from the vertical.)

Totally Enclosed Motor

The totally enclosed enclosure type prevents the free exchange of air between the inside and outside of the case, but is not airtight.

Totally Enclosed Non-Ventilated (TENV) Motor

The totally enclosed non-ventilated enclosure type is not equipped for cooling by external devices.

Totally Enclosed Fan-Cooled (TEFC) Motor

The totally enclosed fan-cooled enclosure type has a shaft-mounted fan to blow cooling air across the external frame. It is a popular motor for use in dusty, dirty, and corrosive atmospheres.

Totally Enclosed Blower-Cooled (TEBC) Motor

The totally enclosed blower-cooled enclosure type is totally enclosed and is equipped with an independently powered fan to blow cooling air across the external frame. A TEBC motor is commonly used in constant torque, variable-speed applications.

Encapsulated Motor

The encapsulated enclosure has windings that are covered with a heavy coating of material to protect them from moisture, dirt, abrasion, etc. Some encapsulated motors have only the coil noses coated. In motors with pressure-embedded windings, the encapsulation material impregnates the windings, even in the coil slots. With this complete protection, the motors can often be used in applications that demand totally enclosed motors.

Explosion-Proof (TEXP) Motor

The explosion-proof enclosure is totally enclosed and built to withstand an explosion of gas or vapor within it. It also prevents ignition of gas or vapor surrounding the machine by sparks, flashes, or explosions that may occur within the machine casing.

Protection and Ratings

Motor Protection

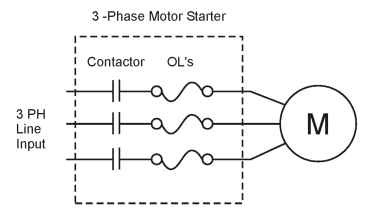

The typical method of starting a three-phase induction motor is by connecting the motor directly across the power line. Line starting a motor is done with a three-phase contactor. To adequately protect the motor from prolonged overload conditions, motor overloads are installed, typically in the same enclosure as the three-phase contactor. These overloads (OLs) operate as heater elements—heating to the point of opening the circuit, and mechanically disconnecting the circuit (Figure 3-31).

Figure 3-31. Line starting a motor

Overloads can be purchased with a specific time designed into the element. Classes 10, 20, and 30 are the usual ratings for industrial use. A class 10 overload indicates that the overload will allow 600% inrush current for 10 s before opening the circuit. Class 20 overloads would allow 600% inrush current for 20 s, and a class 30 would allow 30 s of operation. The current draw from a typical induction motor, as well as the torque produced can be seen in Figure 3-32.

Line starting an induction motor, as shown in Figure 3-32, would allow the motor to develop rated torque, as soon as the motor starter button is pressed. This is because across the line, the motor has the benefit of full voltage, current, and frequency (Hz). As long as the input power is of rated value, the motor would develop the torque as seen in Figure 3-32, from zero to base speed.

Figure 3-32. Motor torque and inrush current (line starting)

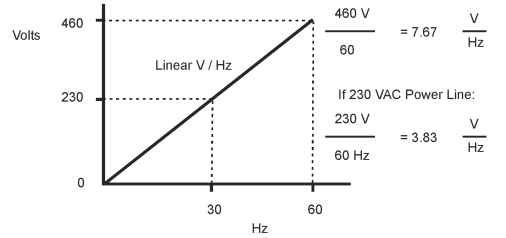

If the ratio of voltage to hertz is maintained, then the motor will develop the rated torque that it was designed to produce. This relationship can be seen in Figure 3-33 and is designated the volts per hertz ratio (V/Hz).

Figure 3-33. Volts per Hz ration (V/Hz)

As seen in Figure 3-33, the V/Hz ratio is calculated by simply dividing the input voltage by the hertz. This characteristic is an important ingredient of AC drive design, which will be covered in the next topic.

There may be applications where full torque is not desirable when the motor is started: a conveyor application in a bottling line, for example. If the feed conveyor has uncapped full bottles on the conveyor, full torque when the conveyor is started would be a not-so-good situation. (The bottles would spill all of their contents.) In cases like that, a reduced torque type of start would be required. There are also cases where full voltage and

hertz, which causes 600% inrush current, would cause a serious power dip on the utility system. High-horsepower motors connected to compressors would be an example. In these cases, a reduced voltage start would be required. If the voltage is less than rated value, the motor would not develop rated torque (according to the V/Hz ratio listed in Figure 3-32). Reducing the V/Hz ratio also reduces the starting current, which means there is less of a power dip.

Reducing the starting current may be accomplished in any one of the following ways.

Primary Resistor or Reactance

The primary resistor or reactance method uses series reactance or resistance to reduce the current during the first seconds. After a preset time interval, the motor is connected directly across the line. This method can be used with any standard induction motor.

Auto Transformer

The auto transformer method uses an auto transformer to directly reduce voltage and the current for the first few seconds. After a preset time interval, the motor is connected directly across the line. This method can also be used with any standard induction motor.

Wye-Delta

The wye-delta method applies the voltage across the Y connection to reduce the current during the first few seconds. After a preset time interval, the motor is connected in delta mode permitting full current. This type of induction motor must be constructed with wye-delta winding connections.

Part-Winding

The part-winding method uses a motor design that has two separate winding circuits. Upon starting, only one winding circuit is engaged and current is reduced. After a preset time interval, the full winding of the motor is connected directly across the line. This type of motor must have two separate winding circuits. To avoid winding overheating and damage, the time between first and second winding connections is limited to 4 seconds maximum.

Motor Ratings

When reviewing ratings, it is also necessary to review several design features of the induction motor. Induction motor design classifications, characteristics, and ratings will now be reviewed in detail.

Because of the variety of torque requirements, NEMA has established different “designs” to cover almost every application. These designs take into consideration starting current and slip, as well as torque. These motor design classes should not be confused with the various classes of wire insulation, which are also designated by letter.

Table 3-3 indicates the various NEMA design classifications and suitable applications.

| Design class | Starting current | Locked rotor torque | Breakdown torque | % Slip |

Suitable Applications Fans, blowers, rotary pumps, unloaded compressors, machine tools, misc. Constant speed load. |

| A | High | Med. Torque | High | 5% Max |

Fans, blowers, rotary pumps, unloaded compressors, machine tools, misc. Constant speed load. |

| B | Medium | Med. torque | High | 5% Max | Fans, blowers, rotary pumps, unloaded compressors, machine tools, misc. Constant speed loads. |

| C | Medium | High torque | Medium | 5% Max |

High-inertia starting (e.g., centrifugal blowers, flywheels, crushers. Loaded starts (e.g., piston pumps, compressors, conveyors). Constant load speed. |

| D | Medium | Extra-high torque | Low | 5-13% | Very high inertia, loaded starting. Considerable variation in load speed (e.g., punch presses, shears, forming machine tools, cranes, hoists, elevators, oil pump jacks) |

| LU | Medium to high | Medium to high | Medium to high | 75% | Pumps, fans, and blowers |

Table 3-3. NEMA torque designs for polyphase motors

Figure 3-34 indicates the relative differences in torque, given a specific motor NEMA design class. The motors indicated are all line started.

As seen in Figure 3-34, the major differences are in the starting torque and peak or breakdown torque capabilities.

Efficiency

The efficiency of a motor is simply the ratio of the power “out” to the power “in,” expressed in percentage.

![]()

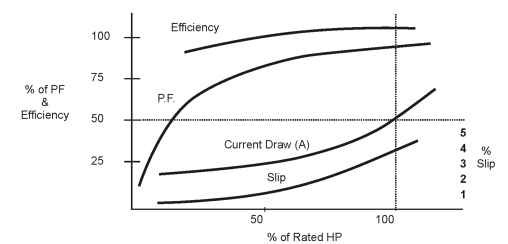

Figure 3-35 illustrates the general relationship between current, slip, efficiency, and power factor.

Figure 3-34. Comparison of NEMA Designs (speed/torque characteristics)

Generally, motor efficiency is relatively flat from rated load to 50% of rated load. Some motors exhibit peak efficiency near 75% of rated load.

Power Factor

Power Factor (P.F.) is the ratio of real power to apparent power, or kW/ kVA. Kilowatts (kW) are measured with a wattmeter, and kilovolt-amperes (kVA) are measured with a voltmeter and ammeter. A power factor of one (1.0) or unity is ideal. Power factor is highest near rated load, as seen in Figure 3-35. Power factor at 50% load is considerably less and continues to dramatically decrease until zero speed.

Figure 3-35. Speed, slip, efficiency and power factor relationships

Current Draw

Current draw in amperes is proportional to the actual load on the motor in the area of rated load. At other loads, current draw tends to be more nonlinear (Figure 3-35).

Locked Rotor (kVA/HP)

Another rating specified on motor nameplates is locked rotor kVA per horsepower. (Some manufacturers use the designation locked rotor amps.) A letter appears on the nameplate corresponding to various kVA/HP ratings. Refer to

Table 3-4 for letter designations.

| Code letter | kVA/HP |

| A | 0-3.14 |

| B | 3.15-3.54 |

| C | 3.55-3.9 |

| D | 4.0-4.4 |

| E | 4.5-4.9 |

| F | 5.0-5.5 |

| G | 5.6-6.2 |

| H | 6.3-7.0 |

| J | 7.1-7.9 |

| K | 8.0-8.9 |

| L | 9.0-9.9 |

| M | 10.0-11.1 |

| N | 11.2-12.4 |

| P | 12.5-13.9 |

| R | 14.0-15.9 |

| S | 16.0-17.9 |

| T | 18.0-19.9 |

| U | 20.0-22.3 |

| V | 22.4 and above |

Table 3-4. Locked rotor kVA per HP

The nameplate codes are a good indicator of the starting current in amperes. A lower code letter indicates a low starting current and a high code letter indicates a high starting current for a specific motor horsepower rating. Calculating the starting current can be accomplished using the following formula:

Example: What is the approximate starting current of a 10-HP, 208-V motor with a nameplate code letter of “K” ?

Solution: From Table 3-4, the kVA/HP for a code letter of “K” is 8.0 to 8.9. Taking a number approximately halfway in-between and substituting in the formula, we get:

Therefore, the starting current is approximately 236 amperes. The starting current is important because the purchaser of the motor must know what kind of protection (overload) to provide. The installation must also include power lines of sufficient size to carry the required currents and properly sized fuses.

Insulation Systems

An insulation system is a group of insulating materials in association with conductors and the supporting structure of a motor. Insulation systems are divided into classes according to the thermal rating of the system. Four classes of insulation systems are used in motors: class A, B, F, and H. Do not confuse these insulation classes with motor designs previously discussed. Those design classes are also designated by letter.

Another confusion factor is the voltage insulation system classes of the sta-tor windings. Those classes are also designated by class B, F, and H, for example. NEMA, standard MG1, part 31 indicates the voltage insulation classes, relative to use on AC drives. More review of motor voltage insulation characteristics will be done in topic 4.

At this point, we will review the temperature insulation classes, common in standard industrial induction motors operated across the line.

Class A. Class A insulation is one in which tests have shown suitable thermal endurance exists when operated at a temperature of 105°C. Typical materials used include cotton, paper, cellulous acetate films, enamel-coated wire, and similar organic materials impregnated with suitable substances.

Class B. Class B insulation is one in which tests have shown suitable thermal endurance exists when operated at a temperature of 130°C. Typical materials include mica, glass fiber, asbestos, and other materials, not necessarily inorganic, with compatible bonding substances having suitable thermal stability.

Class F. Class F insulation is one in which tests have shown suitable thermal endurance exists when operated at a temperature of 155°C. Typical materials include mica, glass fiber, asbestos, and other materials, not necessarily inorganic, with compatible bonding substances having suitable thermal stability.

Class H. Class H insulation is one in which tests have shown suitable thermal endurance exists when operated at a temperature of 180°C. Typical materials used include mica, glass fiber, asbestos, silicone elastomer, and other materials, not necessarily inorganic, with compatible bonding substances, such as silicone resins, having suitable thermal stability.

Usual Service Conditions

When operated within the limits of the NEMA-specified “usual service conditions,” standard motors will perform in accordance with their ratings.

For service conditions other than usual, the precautions listed below must be considered.

Ambient or room temperature not over 40°C. If the ambient temperature is over 40°C (104°F), the motor service factor must be reduced or a higher horsepower motor used. The larger motor will be loaded below full capacity so the temperature rise will be less and overheating reduced. (Note: Service factor refers to rated motor power and indicates permissible power loading that may carried by the motor. For example, a 1.15 service factor would allow 15% overload power to be drawn by the motor.)

Altitude does not exceed 3300 feet (1000 meters). Motors having class A or B insulation systems and temperature rises according to NEMA can operate satisfactorily at altitudes above 3300 feet. However, in locations above 3300 feet, a decrease in ambient temperature must compensate for the increase in temperature rise, as seen in Table 3-5.

| Ambient temp. °C (°F) | Max. altitude (ft) |

| 40 (104) | 3300 |

| 30 (86) | 6600 |

| 20 (68) | 9900 |

Table 3-5. Temperature vs. altitude

Motors having a service factor of 1.15 or higher will operate satisfactorily at unity service factor and an ambient temperature of 40°C at altitudes above 3300 feet up to 9000 feet.

Voltage Variations. A voltage variation of not more than ±10% of name-plate voltage:

Operation outside these limits or unbalanced voltage conditions can result in overheating or loss of torque and may require using a larger-horsepower motor.

Frequency Variations. A frequency variation of not more than ±5% of nameplate frequency: Operation outside of these limits results in substantial speed variation and causes overheating and reduced torque.

A combination of 10% variation in voltage and frequency provided the frequency variation does not exceed 5%.

Mounting Surface and Location. The mounting surface must be rigid and in accordance with NEMA specifications. Location of supplementary enclosures must not seriously interfere with the ventilation of the motor.

AC Motor Types

Introduction

AC motors can be divided into two major categories—asynchronous and synchronous. The induction motor is probably the most common type of asynchronous motor (meaning speed is dependent on slip). When reviewing induction motors, there are two rating designations—NEMA and IEC.

Another type of asynchronous motor is the wound rotor motor. This type of motor has controllable speed and torque because of the addition of a secondary resistance in the rotor circuit. A third type of popular asynchronous motor is the single-phase motor. The single-phase AC motor will not be covered because of their limited use in industrial applications when connected with variable-frequency drives.

The synchronous motor is inherently a constant-speed motor, when operated directly across the line. This type of motor operates in synchronism with the line frequency. Two types of synchronous motors are non-excited and DC-excited.

The basic principles of AC induction motors have been previously covered. In this section, attention will be given to motor designations, ratings, and designs.

Standard AC Induction Motors (NEMA and IEC)

NEMA frame motors are in widespread use throughout U.S. industry. This motor design was developed before the 1950s and has well served many types of fixed-speed applications. In 1952 and 1964, NEMA evaluated standard frame sizes and re-rated the frame standards. The result was smaller diameter motor frames (e.g., original 326 frame prior to 1952, to a 284U frame in 1952, to a 256T frame in 1964). As the re-rating took place, the frame sizes (numbers) were reduced, as was the amount of iron in the stator. With less iron in the stator, less overload capability is realized compared with the “U” frame or the original frame size.

However, with smaller-diameter frames comes more efficiency and faster response to changes in magnetic flux. Figure 3-36 indicates the construction of a standard AC induction motor. All the major motor components are identified.

It should be noted that all standard motors include a small rectangular slot, cut lengthwise in the shaft, called a keyway or keyseat. This slot includes a tapered-cut rectangular piece of steel, call a key. The key is inserted into the keyway and pressure-fit snugly to mechanically connect the shaft and coupler or connection device, such as a pulley or gear.

As seen in Figure 3-36, the induction motor is a fairly simple device. However, precision engineering is required to create small tolerances and air gaps that will allow maximum efficiency and torque generation.

Figure 3-36. AC induction motor construction

The AC induction motor (polyphase induction motor) can be divided into five classifications, according to NEMA. The speed/torque characteristics for each classification have been presented in an earlier section. A brief description of each classification will be presented here, followed by a comparison to IEC frame motors.

• NEMA Design A: This type of motor has a high breakdown torque characteristic, compared with NEMA design B motors. These motors are normally designed for specific use, with a slip characteristic usually less than 5%.

• NEMA design B: This type of motor is designed for general-purpose use and accounts for the largest share of induction motors sold. The typical slip for a design B motor is 3-5% or less.

• NEMA design C: This type of motor has a high starting torque, with a relatively normal starting current and low slip. The type of load applied to a design C is one where breakaway loads are high upon start. The loads, however, would be normally run at the rated point, with very little demand for overload.

• NEMA design D: This type of motor has a high starting torque, high slip, but also low full load speed. Because of its high slip (513%), the speed can easily fluctuate because of changes in load.

• NEMA design E: This type of motor is known for high efficiency and is used mainly where the starting torque requirements are low. Fans and centrifugal pumps make up the bulk of applications using this type of motor.

Figure 3-37 indicates the NEMA designs and compares design with rated starting current and speed.

As shown in Figure 3-37, though design E may have the highest efficiency, it also has the highest starting current—about 800%. This fact must be reviewed when sizing the proper overload heater elements. Most standard induction motors have closer to a 600% starting current rating.

Figure 3-37. Current vs. speed for NEMA motor designs

Though NEMA motors are rated in horsepower, there are times when a motor is specified on the basis of its frame size. NEMA supplies standard frame designations, up to the 445T frame. Above that rating, motor manufacturers can supply their own standards and designate the motor rating as exceeding the NEMA ratings.

There are standard frame sizes of motors and are based on a given horsepower or base speed. NEMA designates a foot to centerline dimension as an indication of the frame size. There is also a designator for frame diameter. Figure 3-38 indicates an AC induction motor, with an indication of frame size.

Figure 3-38. 324 frame motor designation

Using a 324 T frame motor as an example, the motor designer designates the shaft centerline distance to the foot at 8 inches. To figure any shaft centerline distance to foot, divide the first two digits of the frame number by 4 (32 -f- 4 = 8 inches). With this information, an application engineer can design a machine with the motor dimensions in mind. This also assists in comparing one motor with one from another manufacturer. All motor dimensions are standard.

Since motor dimensions are standard, so too are motor nameplate ratings. As with DC motors, AC motor nameplates contain all the necessary information to effectively apply the motor. Figure 3-39 is an example of a typical AC motor nameplate.

Figure 3-39. AC motor nameplate

• Frame: Indicating the frame rating per specific horsepower, given the rated voltage and frequency (example: 256T frame).

• HP: Available horsepower at the designated voltage and frequency ratings.

• Voltage, phase, and frequency: Designations for the rated voltage, phase, and frequency in hertz. Many industrial motors contain a dual-voltage rating. This means that they can be connected to two different voltage lines. The operating voltage is designated by either jumper strips or wire configurations that are completed in the conduit box. Typically, NEMA frame motors are rated for 60-Hz operation.

• FL Amps: Current rating of the motor, listed in amperes. Some nameplates indicate current rating as FLA (full load amps). This would indicate that the motor would draw the stated amps under rated voltage, frequency, and load. If the motor is a dual-voltage motor, two values of amps would be listed. The first value would coincide with the first value of voltage stated. The second value would coincide with the second voltage value listed. (Example: A 230/460V motor may indicate nameplate amps of 68/34 amps. The motor would draw twice the amps on the 230-V connection, compared with the 460-V connection.)

• rpm: This is the motor speed in rpm at base speed. Base speed is indicated as rated voltage, frequency, and load. Due to less slip, an unloaded motor speed would rise from this speed to close to synchronous speed.

• Design and insulation class: The design class would indicate the NEMA designation for A, B, C, D, or E. Typically, the insulation class would indicate the temperature capability of the stator winding insulation. For example, a common designation of Class B insulation would allow for a maximum temperature rise of 130°C (266°F). A Class H insulation would allow for a maximum temperature rise of 180°C (356°F). Temperature rise means the amount of temperature increase, above the normal ambient rating of 40°C (104°F).

An additional classification is now being included with motors—that of the electrical strength of the stator winding insulation (referred to a dielectric strength). AC motors applied to variable-frequency drives run the risk of possible insulation damage from the power conversion technology in the drive. Voltage stress beyond the rating can cause microscopic pin holes in the insulation, which could result in an open phase and eventual motor failure. Motors designated as inverter duty have the electrical insulation strength to avoid failure due to drive technology issues.

NEMA MG-1, Part 31 standards indicate that motors operated on 600 V or less drives should be capable of withstanding peak voltage of 1600 V. Motor cable length and drive carrier (switch) frequency also play a part in the possible damage to a motor’s insulation strength. Motors with a 1200-V or 1000-V insulation strength should not be applied to AC drives unless additional precautions are taken. Special drive output filters will reduce the effects of high-peak voltages and lower the risk of insulation failure.

The motor manufacturer should always be consulted when questions arise regarding the insulation strength of the windings. The manufacturer can make recommendations as to additional safeguards that may be needed to increase motor life when connected to a drive.

• Duty and S.F. (Service Factor): Most standard AC motors list duty as “continuous” or “intermittent.” The service factor of the

motor is the multiplier or additional safe power loading above the rating. Small fractional horsepower motors may carry a service factor of 1.4, while larger integral horsepower motors may list only 1.15 service factor. For example, a 1.15 S.F. would indicate a motor’s capability of 15% additional horsepower output, above the rating. A 1.4 S.F. would indicate 40% additional horsepower output.

• Efficiency and Ambient: Many motors may list a designation of premium efficiency. In addition, an actual number may be referenced, such as 89.5. The efficiency is closely tied with the NEMA classification, such as design A, B, C, etc. The motor manufacturer will acquire the rating from an independent testing agency. The ambient temperature is the maximum normal operating temperature, below the amount indicated in the temperature insulation class.

Not all AC motors contain every piece of data listed above. But all motor nameplates would indicate the most important information, such as voltage, frequency, amps, and rpm. This information is required by an AC drive, in order for the drive to match internal diagnostics with the motor data.

Some motor nameplates indicate a wiring diagram for the dual voltage windings; others have a sticker or label inside the conduit box, stating the wiring connections. Some of the new motors manufactured today indicate the dielectric strength of the insulation or mounting design.

IEC Ratings

At this point, it would be helpful to briefly review IEC motor ratings and then compare IEC with NEMA. The motor market today has become more global, with IEC rated motors on equipment exported from Europe.

IEC is the acronym for the International Electrotechnical Commission. IEC, like NEMA, establishes and publishes mechanical and electrical standards for motors. Many IEC standards have been nationalized for a specific country, such as Germany, Great Britain, or France.

Though NEMA and IEC standards use different terms, they are essentially similar in ratings and in many cases are interchangeable. NEMA standards are probably more conservative, which allows for interpretations in design. IEC standards are more specific and categorized. They are typically more precise.

Both IEC and NEMA use letter codes to indicate mechanical dimensions. They also use code letters to indicate general frame size. The NEMA and IEC dimension codes are not interchangeable, nor are the frame sizes (exception being the 56 frame, which is the same in NEMA and IEC).

As expected, NEMA designations are listed in inches and horsepower, whereas IEC designations are listed in millimeters and kilowatts. NEMA lists a handful of enclosure designations and descriptions, whereas IEC uses numbers.

IEC lists two numbers: the first number indicates protection against solid objects; the second number indicates protection against water entry. The enclosure letters “IP” indicate ingress protection. (Example: IP55. The first “5″ indicates complete protection, including dust-tight, and the second “5″ indicates protection from water sprayed from a nozzle from any direction. This type of motor would be considered wash-down duty.)

NEMA would list the enclosure type to indicate the particular cooling method employed in the motor. IEC, however, would use a letter and number code to designate how a motor is cooled. (Example: IC40. The “4″ indicates frame cooling, while the “0″ indicates convection cooling with no fan.) The temperature insulation class ratings are identical, whether

NEMA or IEC.

IEC motors are listed as “50 Hz” rather than the NEMA “60 Hz.” A 50-Hz IEC motor will normally operate satisfactorily on 60 Hz, as long as the voltage is increased by the same ratio as the frequency. (Example: 50 Hz at 380 V to 60 Hz at 460 V) The motor speed would be 1/6 higher than at 50 Hz. However, operating a 50-Hz motor at the lower U.S. voltage of 230 V may not operate satisfactorily without derating (requiring the motor to deliver 15 or 20% less torque at nameplate rating, due to motor heating).

When applying an IEC motor instead of a NEMA motor, it is always sound practice to consult a motor rating table for comparisons. NEMA ratings include a factor for overload, whereas IEC strictly rates motors with little to no overload capability.

Wound Rotor

The speed and torque characteristics of an AC induction motor are essentially defined by the design, number of poles, and line power applied. In contrast, the wound rotor version of an induction motor does have controllable speed and torque characteristics. Different values of resistance are inserted into the rotor circuit to obtain various performance options.

Wound rotor motors are normally started with a secondary resistance connected to the rotor circuit. The resistance is reduced to allow the motor to increase in speed. This type of motor can develop substantial torque, and at the same time, limit the amount of locked rotor current. The secondary resistance can be designed for continuous operation at reduced speeds. Special consideration is required for heat dissipation at reduced speeds because of reduced cooling effects and high inertia loads. Figure 3-40 indicates a wiring diagram of a wound rotor motor.

Figure 3-40. Wound rotor motor diagram

The advantages of this type of motor include a lower starting current (less than 600%) with a high starting torque. This motor type also provides for smooth acceleration and easy control capability.

A disadvantage of this type of motor is that efficiency is low. The external resistance causes a large drop in rpm, based on a small change in load. Speed can be reduced down to 50% of rated value. Another disadvantage is that the relative cost of this motor may be substantially higher than an equivalent three-phase induction motor.

Synchronous Motors

The three-phase AC synchronous motor is a unique and specialized type of motor. Without complex electronic control, this motor type is inherently a fixed-speed motor. This type of motor is used in applications where constant speed is critical. It is also in cases where power factor correction is desired, since it can operate at leading or unity power factor. The synchronous motor is a highly efficient means of converting AC electrical power to mechanical power.

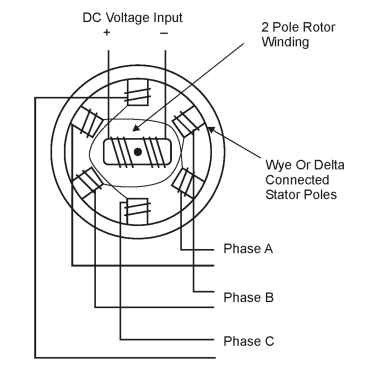

The synchronous motor could be considered a three-phase alternator, operated backward. Direct current is applied directly to the rotor to produce a rotating electromagnetic field. The stator windings are connected in either a wye or delta configuration. Figure 3-41 indicates a diagram of the synchronous motor.

It should be noted that the synchronous motor has a “wound” rotor that is connected to a brush assembly system connected to DC power. In reality, synchronous motors have little to no starting torque. An external device must be used for the initial start of the motor.

Devices such as an auxiliary DC motor/generator or damper windings are typically used to initially start the synchronous motor. The motor is constructed such that it will rotate at the same speed as the rotating stator field. At synchronous speed, rotor and stator speed are equal, and therefore, the motor has no slip. With a load on the shaft, slip increases and the

Figure 3-41. AC synchronous motor diagram

motor responds with more torque, which increases the speed back to “synchronism.”

Synchronous motors in sub-fractional ratings are usually self-excited using damper windings. High-horsepower synchronous motors are usually DC excited using an external DC motor/generator.

Multiple Pole Motors

Multiple pole motors could be considered multiple-speed motors. As stated earlier, the speed is a direct result of the number of pole pairs. At 60 Hz, a four-pole motor would have a synchronous speed of 1800 rpm. At the same 60 Hz, a two-pole motor would have twice the synchronous speed— 3600 rpm. Typically, an AC induction motor has only one set of pole pairs—2, 4, 6, or 8 poles, or more. However, specially designed multiple speed motors would be wound for two different pole pair connections.

Most of the multiple pole motors would be dual-speed or two-speed design motors. Essentially, the conduit box would contain two sets of wiring configurations: one for the low-speed and one for the high-speed windings. The windings would be engaged by a two-position switch or electrical contacts. The switch or contacts would connect either the low- or high-speed winding to the three-phase power source.

This type of motor configuration provides a certain amount of flexibility in manufacturing. Perhaps the low-speed winding would be used for a production process taking place on a feed conveyor. Once the process is com-

plete and a limit switch is closed, that same conveyor would move the product at high speed to the packaging and labeling section. There are many other industrial, packaging, food processing, and HVAC applications where two-speed motors could be an advantage. The possible disadvantage of this type of motor is the additional cost of some type of external switch control.

Specialty Motors

General Principles of Operation—Stepper

A step or stepper motor is one in which electrical pulses are converted into mechanical movements. A standard DC motor, for example, rotates continuously; but a stepper motor rotates in fixed increments whenever it is pulsed on. A standard DC motor would be considered an analog device, while a stepper motor would be considered digital.

The size of the step, or the step angle, is determined by the motor construction or by the type of controller connected. (Note: The step angle is determined in fractions of 360°, which is one complete shaft rotation.) For example, the step resolution of 90° would be four steps per rev (revolution). A 15° resolution would indicate 12 steps per rev, and 1.8° would indicate 200 steps per rev. Microstep motors are capable of thousands of steps per rev.

Because of their exactness of rotation, stepper motors are used, “open-loop” in control systems where position is critical. In many high-accuracy applications, an encoder or position feedback device is used to confirm the actual position of the motor shaft.

Stepper motors require a drive package with an electronic controller, power supply, and feedback device, if needed. Figure 3-42 indicates the principle of stepper motor design.

The stepper motor is a two-phase type of motor. The indexer provides step and direction pulses to the drive controller (amplifier). The amount of current for each phase is determined by the controller, which is then used as an output to the stepper motor. The stepper motor is operated by pulses, which determine the “steps” of the motor shaft. The frequency of these steps determines the speed of the motor.

The most common types of stepper motors are probably the permanent magnet (PM) and the variable reluctance (VR). The diagram in Figure 342 is one type of a PM stepper motor. Is could be considered a design similar to the synchronous induction motor.

The rotor moves in step with the stator windings when the windings are energized. If the windings are continuously energized from the two-phase supply, then the motor would essentially act as a low-speed synchronous motor. As seen in Figure 3-42, the PM rotor is surrounded by the two-phase stator. The rotor sections are offset by 1/2 tooth pitch (180°) from

Figure 3-42. PM stepper motor diagram

each other. As the voltage rotates clockwise, from phase A to phase B, a set of rotor magnets will align themselves with the stator magnetic field. The rotor will therefore turn one step. If for some reason, both phases are energized simultaneously, the rotor will establish a location midway between the stator poles. If that were to happen, the motor would be considered half stepping.

The VR type stepper motor is basically constructed the same way as a PM motor. The difference is that the VR type does not have magnets in the rotor. It would contain, however, 2-, 3- or 4-phase stator windings. The motor would operate similar to an induction motor, with the rotor aligning itself with a stator pole that is energized.

The stepper motor is essentially a brushless motor. It can deliver high torque at zero speed, with no drifting of the shaft position. The direction of the motor can be reversed by reversing the direction of the pulses from the controller. The device has low inertia, similar to a servomotor, a result of the windings in the stator and a permanent magnet rotor.

There are several application considerations that come with stepper motors. Periodically, possibly at low speeds, this type of motor exhibits oscillations with every step. This is caused by poles in the rotor seeking the next available magnetic field. Many times, the magnetic fields of the rotor and stator do not match up, typically upon power-up. Also, the motor, controller, and load must be somewhat matched to minimize the oscillations. Stepper motors tend to run hotter than standard induction motors. This is due to the pulse waveform from the controller, especially at low

speed, with high current levels present (a product of high torque response at low speed).

AC Vector Motors

This type of motor is a specific type that would be applied to an AC vector or flux vector drive. Principles of operation for this motor are basically identical to the standard AC induction motor. Because this motor is operated from a flux vector drive, special design characteristics are required.

Vector control basically means the requirement of full torque at zero speed. In applications such as elevators, hoists, and ski lifts, the motor usually is started while under rated load. If the device is an elevator car, the position of the device cannot change when the motor is started. If a standard induction motor were used, the motor would have to “slip back” for torque to be developed. During the process of developing “motor slip,” the elevator car may have dropped several feet before the motor could develop enough torque to move it upward. The vector motor is specially designed to operate at extremely low slip and be able to handle the heat generated by providing full torque at zero speed.

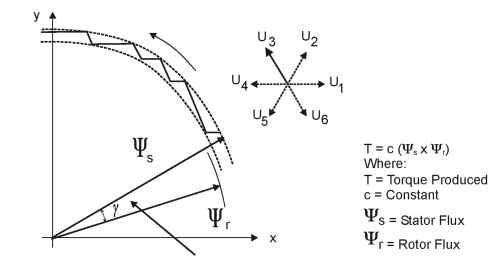

The general principle of operation lies with analyzing the motor in terms of voltage and flux vectors. The rotor is divided into 360° of rotation, which is one complete rotation. A vector would be the direction and amount of a certain quantity in the motor circuit—in this case, rotor flux or stator flux. The relationship between rotor and stator flux is indicated in Figure 3-43.

Figure 3-43. Vector motor relationships – stator and rotor flux

The torque in an induction motor is developed by the relationship of rotor and stator flux. The physical torque developed is a byproduct of the magnitude of the stator and rotor flux vectors. Stator flux is a function of the input voltage to the motor. (The voltage vectors are indicated by U1 to U6 in the figure.) We could consider the dashed curve set the torque span

developed in the motor. The device that would control the amount of sta-tor and rotor flux generated would be considered a vector or flux vector AC drive.

The vector motor, in most cases, must have provisions for the mounting of a feedback device on the shaft end. The feedback device (encoder or resolver) sends information back to the drive control, indicating exactly where the rotor position is located. The drive control needs this information to calculate and generate V/Hz. The V/Hz waveform is then used by the motor to generate the flux vectors shown in the figure.

Vector control, drive control, and feedback devices will be discussed in topic 4 (AC Drives section) and topic 5 (Closed Loop Control section). This type of technology is definitely in high demand throughout industry today. The use of motor vector control (torque control) allows manufacturing systems to increase accuracy and productivity. The basic design of the AC induction motor has not changed much in the last few decades. Magnetism is magnetism. However, the ratings are now more precise than they were a few decades ago. The efficiencies are definitely higher than a few decades ago. There are AC drive manufacturers that require a flux vector drive and motor combination—a matched set. The direction of industry, however, is to be able to use a combination of vendor equipment to achieve the desired results.