Introduction

Serial numbers are present on many everyday objects. They are used to distinguish items from others of a similar appearance. In most instances, they are simply a sequential number, which describes how many units in a particular production sequence have been produced. In some cases, they are encoded to carry information about the product, such as date of manufacture, model type, etc.identify a shoe, providing the characteristic was sufficiently clear and detailed, and reflected sufficient significant features in common with the scene impression. An example would be a feature generally shaped like an ‘X’ with one stem of the ‘X’ longer than the other, and terminating in a slight curve. If a characteristic such as this were of the same size, shape, position and orientation on both a crime scene impression and a shoe sole of the same design, it could be sufficient alone to permit a positive identification. However, should a characteristic be less clear or contain fewer features, such as a very tiny hole, more than one characteristic would be needed for identification.

Serial numbers are regularly removed from items in order to hide their true identity. The reasons for the removal are varied, and include:

• the perpetration of fraud, such as portraying an item to be of a different value when making an insurance claim;

• to hide the origin of items used in the commission of a crime, such as removing the number from a firearm used in a murder;

• to prevent positive identification of stolen property.

The Footwear Impression Expert

Footwear impression examinations should be made by persons who have received additional specialized training and are experienced in that discipline. Being qualified as an expert in other forensic disciplines is not, in itself, qualification to conduct examinations between questioned footwear impressions and known shoes. Examiners in this field should be afforded specific training and experience under the direct supervision of an experienced and qualified footwear impression examiner. This normally includes working cases and practical exercises of sufficient quantity over an extended period of time to enable the trainee examiner to acquire the necessary skills and knowledge related to this forensic discipline. Reading the available literature, attending specific courses, seminars and workshops, touring footwear manufacturing facilities and conducting research are ways of obtaining further knowledge.

Serial numbers can be applied to objects by way of adhesive labels, or direct impression on to the actual object. Generally, direct application on to the object is used when the item is composed of metal, and labels are used on plastic items. Inevitably, there are exceptions to this. Cameras, for example, may carry serial numbers stamped directly into a polymer section of the body.

Methods of Application

Serial numbers can be applied in a variety of ways, depending upon the substrate to be marked and the environment the number will be used in. The major methods include:

• Die stamping In this technique, a male or ‘inverse positive’ of the character to be stamped is created, and then applied to the substrate under sudden pressure (often by hand). An indented character is left behind. This method is commonly used on metal substrates, particularly in the motor vehicle manufacturing industry. The process is often called ‘cold working’.

• Rolling A similar process to die stamping. In this case, the characters to be stamped are applied to the substrate with a slower, more steady pressure. Its application is in cases in which the substrate could be damaged by the sudden impact used in die stamping.

• Hot stamping Polymer substrates are not amenable to either of the cold working methods described above. However, by heating a die prior to stamping, it can be used to produce a suitable impressed character.

• Pin stamping Small pins are used to form individual dots on the substrate, using an impact process. By arranging these dots into the appropriate pattern, the requisite characters are formed. The process is analogous to dot matrix computer printing.

• Engraving The substrate is cut away by a tiny spinning head or similar, leaving marks which form the serial number. This method is particularly common on plastic substrates, or where numbers are being applied by a consumer (for example, inscribing a driver’s license number on to the back of a video cassette recorder).

• Laser etching A technique that is coming into widespread favor, this effectively involves burning the serial number into the substrate by applying an industrial laser.

• Embossing Involves a technique similar to die stamping or rolling, but is used on thin metal plates to produce a raised print appearance. The die is pushed on to the plate from behind.

• Traditional printing methods A variety of printing techniques can be used to apply serial numbers, especially on to adhesive labels or cloth stock. The methods include ink processes such as offset printing, hot foil stamping, screen printing, laser printing, etc.

Removal Methods

Traditionally, methods used to remove serial numbers involve a physical abrasion of the substrate until the number is no longer visible. Methods to do this include filing, grinding (usually with an electric or air-powered angle grinder), sanding with sandpaper or emery paper, or scraping with a sharp implement, especially on plastic substrates.

Numbers can also be obliterated so that they are no longer decipherable. One method of accomplishing this is called ‘peening’. A relatively sharp object, such as a centre punch or cold chisel, is hammered on to the area of the number until it is damaged beyond legibility.

In the case of printed numbers, chemicals can be used to wash away or blur the numbers. Solvents such as alcohol, acetone or similar can be used.

Restoration Methods

Forensic practitioners are most often confronted with die-stamped serial numbers which have been ground off metal substrates. This is particularly common in cases involving theft of motor vehicles or the use of firearms.

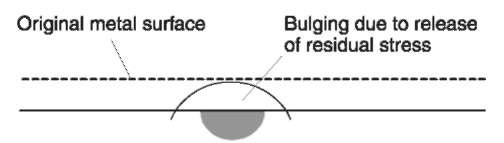

If a number is ground off a surface until no visible sign of the characters remains, it does not necessarily follow that all traces of the number have been obliterated. The process of cold working involves transmitting a shock into the substrate, and compressing the metal structure such that the material which originally occupied the volume taken by the characters is displaced downwards into the substrate (Fig. 1). If the top layer of the substrate is subsequently removed, a damaged area of material underneath the original characters may remain (Fig. 2). Note that a number of factors may influence how far into the substrate the damaged area extends. These include the composition of the material, as well as the force used to stamp the number. If the surface is ground off deeply enough, it is possible that all traces of the damaged area will be obliterated.

Figure 1 Damaged area underneath a stamped character.

Figure 2 Residual deformation still present after obliteration of character.

There are two major methods employed for recovering obliterated serial numbers in metal substrates. These are generally referred to as ‘chemical etching’ and ‘heat treatment’. The purpose of both processes is to create a visible contrast between the damaged and undamaged regions of the substrate. This contrast is the result of differential reflection or scattering of light from the damaged area compared with that from the undamaged area (Fig. 3).

Before either method can be applied, the surface must be prepared. This involves removing as much as possible in the way of residual irregularities, in order to obtain as smooth a surface as possible. A compromise must occasionally be reached when deep grooves are present, as removing the surrounding metal may achieve total obliteration of any remaining traces of the original characters.

Progressively finer grades of waterproof abrasive paper (known as ‘wet and dry’ paper) should be used to gradually smooth out the surface, with the best results being obtained from a mirror-like finish. Some practitioners use small hand-grinding or sanding tools to smooth the surface, but this can run the risk of uncontrolled heating of the area, as well as having less control over the depth of the abrasion. For these reasons, hand sanding is generally preferred.

Chemical etching

This is perhaps the most commonly used technique for recovering obliterated numbers. It originates from metallurgical examinations, in which etching solutions are applied to cross-sections of metal in order to observe the crystal structure under reflected light.

Figure 3 Reflection of light from smooth surface compared to rough surface.

For recovering obliterated numbers, the method relies upon the phenomenon that the rate of reaction between the applied chemicals and the substrate can differ in the damaged and undamaged areas. The damaged area usually has a different electrochemical potential to the undamaged surroundings, so can therefore be attacked selectively, or at least at a different rate, in comparison with the surroundings.

The chemicals used depend upon the composition of the substrate. They range from simple alkaline solutions to complicated mixtures which result in an oxidation/reduction reaction with the metal. Care must be taken when using some of the etching solutions, as they can be corrosive and/or toxic.

The solutions are generally applied by wiping them across the surface of the substrate with a cotton-wool or cloth swab. This process is repeated regularly, and the surface is observed closely between applications. Any visible characters should be noted immediately, as it is quite common for different characters to appear at different times during the restoration. It is also common for some characters to disappear shortly after becoming visible.

Another method of application, particularly useful for aluminum alloy engine block numbers on horizontal surfaces, is to form a dam of plasticene around the area, then pour the etching solution into this to a depth of 2-5 mm. The surface will be observed to bubble, with the recovered characters being visible.

A modification to the standard chemical etching technique is that of ‘electropolishing’. This involves adding an electric current to the etching process. A d.c. power supply is used, with one terminal connected to the body of the substrate, and the other to the swab. This method has found favor in some forensic laboratories, but opinion seems to be divided. In many instances the extra time and equipment required are considered not to produce a superior result.

Heat treatment

This is a highly successful technique, with particular application to restoring obliterated serial numbers on cast-iron substrates. It has one significant advantage, which is speed. A heat treatment can at times be completed in a matter of minutes, whereas chemical etching is generally a much slower process. It again relies upon the residual stresses remaining under the stamped area. However, the visualization technique differs from that of etching. In this method, heat is applied directly to the obliterated area until the metal glows a light cherry red. This results in the release of the residual tensile stresses, and allows the compressed area to bulge above the surroundings (Fig. 4). After heating, the area is lightly rubbed with abrasive paper, which removes any soot or oxide layer from the raised characters. They therefore stand out in contrast to the dark surroundings.

There is no specific temperature at which a heat treatment recovery will take place. Factors including the depth of the impression and the exact composition of the substrate will affect the temperature required. As a guide, the surface should be slowly heated to no more than a cherry red. An oxyacetylene welding torch with a small brazing tip, such as a number 8, is the preferred heating equipment.

It is sometimes possible to see the raised characters before the surface has reached full temperature. If this occurs, there is no requirement to heat further.

In order to avoid cracking the substrate, the area should be heated slowly, and then also allowed to cool slowly. To do this, the heat source should be either gradually turned down or slowly moved away from the surface. This avoids a rapid cooling process.

Heat treatment has been used with limited success on aluminum alloy substrates. A much lower temperature is employed, and it appears preferable to apply the heat to the substrate a short distance away from the obliterated area, and allow conduction to heat the area in question. This is known as ‘indirect heating’.

For thin sheet metal areas, the application of heat treatment does not seem to produce useful results: chemical etching is the preferred technique.

Other methods

A variety of other methods for visualizing obliterated serial numbers on metal objects have been reported but are not in general use. These include the following.

Magnetic particle method In this technique, the object is magnetized and then sprayed with fine magnetic particles. The particles are attracted to regions on the surface where a crack or other damage has occurred. The method has an application in crack testing of aeronautical components, and is suitable for the recovery of serial numbers on small objects such as firearms.

The method has an advantage, in that it is nondestructive, enabling other methods to be tried subsequently if necessary. It does, however, have a significant drawback, which is in the equipment required. To magnetize the object requires either running a high amperage electric current through it, or placing the object in contact with a large magnet. Also, neither of these actions is appropriate if the object happens to be a serial number stamped on an engine still fitted into a motor vehicle.

Figure 4 Bulging of surface following release of residual stress due to application of heat.

Ultrasonic cavitation Cavitation is a phenomenon that involves the formation of bubbles in a liquid due to localized reductions in pressure. The bubbles are of high energy and have the capability to etch metal surfaces.

Recovery of obliterated serial numbers in metal objects is possible if they are placed into a water bath which is excited by an ultrasonic sound frequency. It appears that the etching occurs preferentially at the sites that have been damaged by stamping. The method has the advantage of being applicable to a wide variety of metals and not requiring the use of chemicals. However, it, like the magnetic particle method, is only suitable for small objects. It is also destructive, in a similar manner to chemical etching.

X-Rays The use of radiography in efforts to recover obliterated serial numbers does not appear to be successful. It seems the radiographs are simply not sensitive enough to enable visualization of the minute damaged areas left after removal of a number. However, the method has been successfully used to locate serial numbers that have been hidden with paint or body filler, or by welding another piece of metal on top of the original.

Nonmetal substrates Less commonly encountered in casework are instances of removal of serial numbers from plastic substrates. The recovery methods described earlier are not applicable in these instances.

It appears that a stamped polymer retains a compressed area underneath the characters in a manner analogous to that of metal substrates. To recover the number, it is necessary to apply a method that will swell the substrate, allowing an image of the compressed area to become visible. The methods used to achieve this include applying heat (obviously at a considerably lower level than that applied to metal), polishing or immersing the area in chemicals.

Reagent Recipes

There are numerous formulations for chemicals that will etch different metals. For practical purposes, the major ones of interest are described in Table 1.

Table 1 Common metal etching formulations

| Substrate | Etchant | |

| Cast-iron and steel | 1. | Fry’s reagent |

| 90 g CuCl2 | ||

| 120 ml HCl | ||

| 100 ml water | ||

| 2. | Modified Fry’s reagent | |

| 15 g CuCl2 | ||

| 120 ml HCl | ||

| 75 ml ethanol | ||

| Stainless steel | 1. | Acidified ferric chloride |

| 5g FeCl3 | ||

| 50ml HCl | ||

| 100 ml water | ||

| Aluminum alloys | 1. | Dilute sodium hydroxide |

| 10g NaOH | ||

| 90 g water | ||

| (Some sources suggest up to | ||

| 60% NaOH) | ||

| 2. | Hume-Rothery’s solution | |

| 200 g CuCl2 | ||

| 5ml HCl | ||

| 100 ml water | ||

| 3. | Dilute nitric acid | |

| 25ml HNO3 | ||

| 75 ml water | ||

| 4. | Alternating acid and alkali | |

| 10% NaOH and 10% HNO3 | ||

| applied alternately | ||

| Brass and copper | 1. | Acidified ferric chloride |

| 19gFeCl3 | ||

| 6ml HCl | ||

| 100 ml water | ||

| 2. | Copper chloride solution | |

| 40 g CuCl2 | ||

| 180 ml HCl | ||

| 100 ml water | ||

A variety of chemicals can be used to swell polymer substrates (Table 2).

Photography

The photographic techniques used to record recovered serial numbers are applications of those used in other forensic areas, such as fingerprints and crime scene examination.

For photographing the results of a chemical etch, black and white film has proved to be most suitable.

Table 2 Chemicals used for the restoration of obliterated serial numbers in common polymers

| Substrate | Chemical |

| High density polyethylene (HDPE) | Ethanol |

| Polycarbonate | Ethanol; ethyl ether |

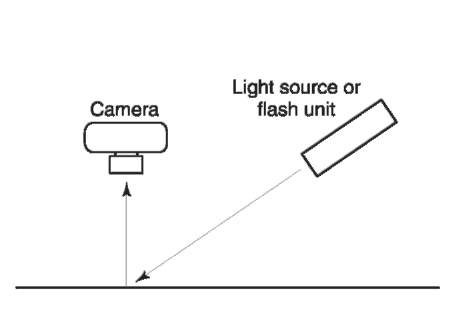

It allows for the contrast between the faint image and the background to be enhanced. A mixture of flash photographs and available light images should be obtained where possible. Oblique lighting appears to produce the best images (Fig. 5). It is often necessary to experiment to determine the best angle for the incident light, depending upon the extent of the recovery, and the nature and location of the surface. A film rated at 400 ASA is suitable, in order to produce images from faint recoveries.

The nature of the recoveries obtained by chemical etching do not always lend themselves to photography. It is possible in some instances to obtain a faint recovery which is decipherable with the naked eye but will not produce a satisfactory image on a photographic film. This reinforces the fact that careful, detailed notes should always be maintained throughout an etching process.

For recording the results of a heat treatment, color film rated about 200 ASA has been found to be appropriate. Again, a mixture of flash and available light photographs should be taken. Interestingly, the results from flash photography appear to be superior in this situation. The best results are often obtained by having the flash unit as closely aligned as possible to the lens of the camera, so that it is almost projecting vertically on to the surface (Fig. 6). This appears to highlight the reflective tops of the raised characters, and can result in some spectacular images.

Figure 5 Oblique lighting used for photographing the results of chemical etching.

Figure 6 Lighting used for photographing the results of heat treatment.