Shape memory response— influence of deformation rate

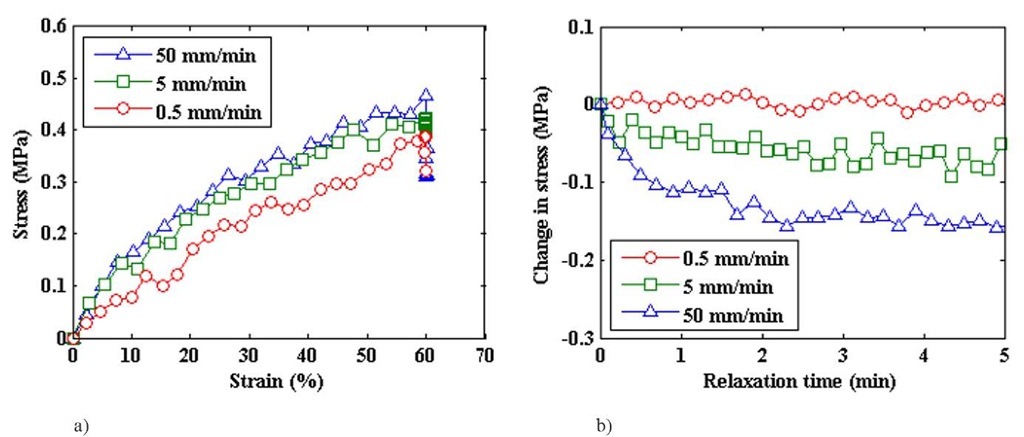

A previous study [7] revealed that Veriflex-E exhibited strain rate sensitivity in axial tension to failure at both room and elevated temperatures. To explore the strain rate sensitivity of the shape memory response of the Veriflex-E, specimens were subjected to shape memory cycles with deformation rates of 0.5, 5, and 50 mm/min from state 1 to 2 in Table 1. The stress-strain curves generated as the sample is strained to 60% at the three deformation rates followed by stress relaxation at a constant strain of 60% (state 2 to 3) were evaluated. The stress-strain results (given in Figure 5a) exhibit rate dependence of the initial linear elastic modulus during loading consistent with the previous study (the modulus increases with an increase in deformation rate). Strain hardening was observed in the previous study beginning near 60% strain, this was a major factor in the selection of 60% as the maximum strain in the current study. The plots of stress drop during relaxation versus relaxation time in Figure 5b show that the change in stress during relaxation is strongly influenced by the prior deformation rate. A larger magnitude drop in stress is observed in relaxation following loading at the deformation rate of 50 mm/min than following loading at 5 mm/min. This larger drop is consistent with results found for other polymers [8, 9] (not exhibiting shape memory capabilities). In contrast, no stress drop is observed during relaxation following loading at 0.5 mm/min.

Fig. 5 Tension to 60% strain at deformation rates of 0.5, 5, and 50 mm/min followed by 5 min stress relaxation periods at constant 60% strain a) stress-strain curve and b) change in stress versus relaxation time during relaxation period

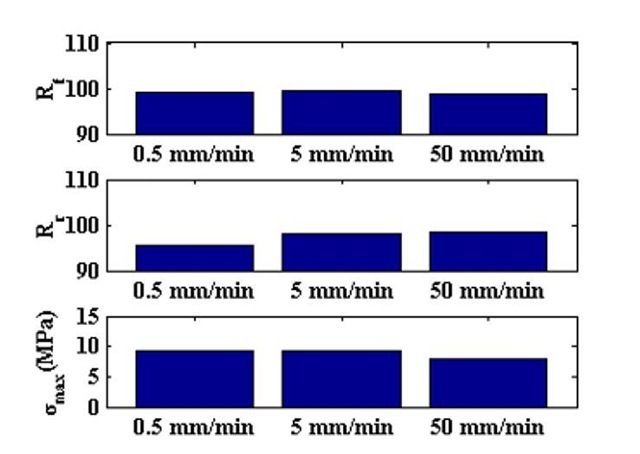

The effects of the prior deformation rate on the shape fixity, shape recovery, and maximum stress were also evaluated. The results shown in Figure 6 represent a single test for the two slower rates and the average of three tests at the 50 mm/min rate. At all three rates, the material exhibits excellent shape fixity (near 100%). There is a slight increase in shape recovery and slight decrease in the maximum stress as the deformation rate is increased. The less time the material is given for configurational changes to take place at elevated temperature (a faster rate deformation takes less time), the less resistance the material produces against locking in the strain and the better the subsequent shape recovery. More repeated testing at the two slower repeats are planned to verify the patterns in this data.

Shape memory response— influence of hold time after deformation

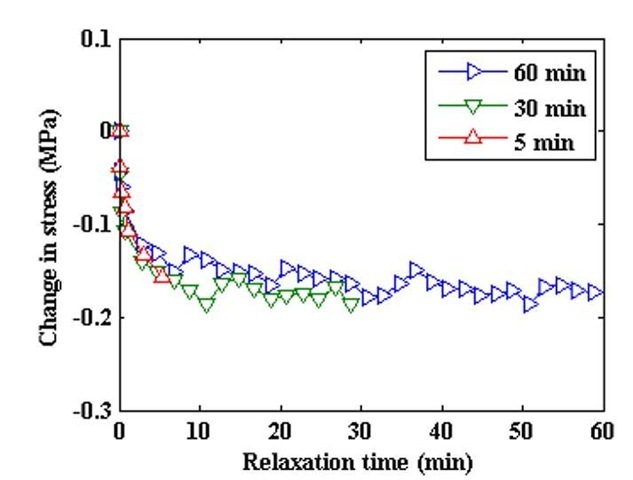

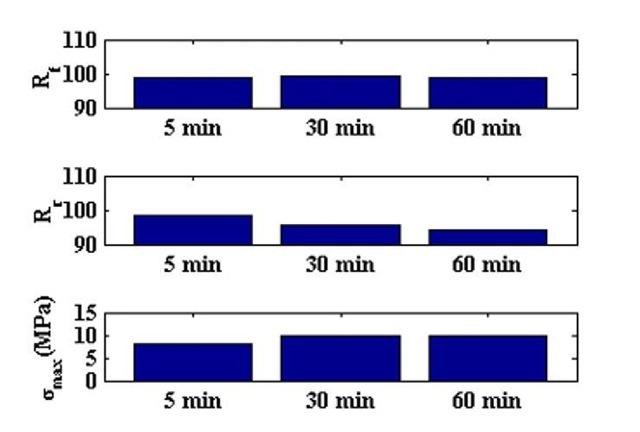

The influence of the hold time following deformation to 60% strain (duration of step 2 to 3 in Table 1) on the shape memory performance was also investigated. The stress relaxation following loading at 50 mm/min is shown in Figure 7 for hold times of 5, 30, and 60 min. The rate of stress drop has already begun to slow by the end of 5 min relaxation time and by 10 min relaxation time a steady stress magnitude has been reached. The effect of this hold time on the shape fixity, shape recovery, and maximum stress were evaluated and shown in Figure 8. There is a slight decrease in shape recovery and slight increase in the maximum stress as the hold time is increased. Once again, the less time the material is given for configurational changes to take place at elevated temperature, the less resistance the material produces against locking in the strain and the better the subsequent shape recovery. More repeated testing at the two slower repeats are planned to verify the patterns in this data.

Fig. 6 Shape fixity, shape recovery, and maximum stress for deformation rates of 0.5mm/min, 5 mm/min, and 50 mm/min (5 min hold time)

Fig. 7 Stress decrease versus relaxation time during relaxation periods of 5, 30, and 60 min (50 mm/min deformation rate)

Fig. 8 Shape fixity, shape recovery, and maximum stress for hold times of 5 min, 30 min, and 60 min (50 mm/min deformation rate)

The shape recovery and maximum stress results from Figures 4, 6, and 8 give evidence that the longer amount of time (slower deformation rate and longer hold time) that the Veriflex-E is subjected to deformation at high temperature, the lower its shape recovery capability and the higher the stresses that are generated during locking in the intended deformation.

Concluding remarks

The shape memory recovery of Veriflex-E degrades with repeated cycles (the residual strain after the cycle increases) and the maximum stress built up during the cycle increases with repeated shape memory cycling (at 50 mm/min deformation rate and 5 min hold time). These changes during repeated cycling would be amplified at slower deformation rates and longer hold times. The shape recovery values are observed to decrease as the deformation rate is decreased and as the hold times are increased. The recovery of the material is faster and more complete for the SMP subjected to the fastest deformation rate up to 60% strain and the shortest hold time following deformation. In addition the maximum stress levels slightly increase as the deformation rate is decreased and as the hold times are increased. Moreover, the elastic modulus increases with an increase in deformation rate during loading to 60% strain, and the stress drop during relaxation is higher for a higher prior deformation rate. The material demonstrates excellent shape fixity regardless of number of cycles, deformation rates, or hold times at high temperature.