Abstract

Building owners and property managers have provided numerous reports of the energy savings obtained from the retrofit installation of energy-control window film to existing buildings. In many cases, substantial energy savings are reported with simple paybacks often within one to four years. However, such claims have not been produced using the rigorous methods prescribed by the International Performance Measurement and Verification Protocol (IPMVP)

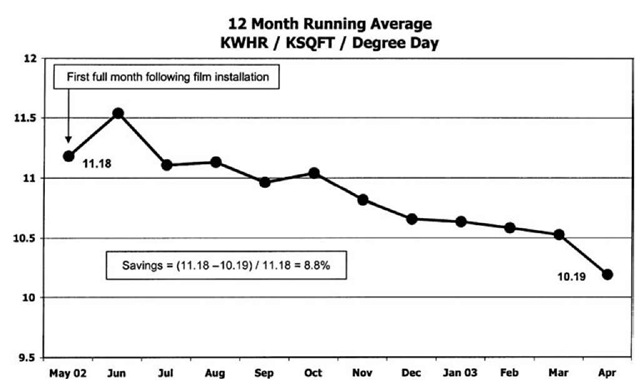

To provide for more definitive evidence of the savings from the use of energy-control window films, CPFilms undertook a demonstration project to install window film on a mid-sized commercial office building and then measure the resulting energy savings using two separate IPMVP methods. The measurement of savings involved the use of IPMVP Option C (whole-building method using utility bill analysis) and Option D (calibrated simulation). During the twelve months following film installation, Option C measured savings of 8.8% were achieved, which includes savings over both the cooling and heating seasons. This compares favorably to Option D calculated savings of 8.4% that were estimated prior to film installation. Both estimates of energy savings demonstrate a simple payback in less than three years.

PROJECT OVERVIEW

In early 2002, CPFilms completed the installation of 9200 ft2 of energy-control window film on an eight-story building in Rockford, Illinois (near Chicago). Fig. 1 shows the building chosen for the demonstration project following completion of window film installation. The building’s conditioned space is 59,000 ft2 and the building’s windows are single-pane bronze tinted glass. The building is heated and cooled using all-electric room unit ventilators.

The window film chosen for this demonstration project was CPFilms’ LLumar® E-1220 Low-E film. As shown in Table 1, addition of this film reduced solar heat gain 67% based on the solar heat gain coefficients (SHGC) of the windows before and after film installation. In addition, the film is constructed with a low-emissivity, or low-e coating that improved the insulating value (U-value) of the single-pane windows by 23%. This improvement in the window’s insulating properties provided additional cooling-season energy savings, beyond the reduction in solar heat-gain, and provided heating-season energy savings by reducing heat loss through the windows.

Rockford has over 6000 heating degree days per year (using a 65°F base). This cool-climate location was chosen to demonstrate that, under the proper circumstances,energy-control window films are an attractive option even in cooler climates and are not simply a “warm climate only” technology, especially when utilizing low-e insulating films. The location was also chosen to show that low-e window films, and the improvement in window insulating properties they offer, can provide substantial energy savings during a prolonged heating season, more than offsetting the loss of “free” solar heat. Negotiations with the building owner prohibited other energy-saving measures from taking place in order to isolate the effects from window film installation.

Before film installation, CPFilms utilized DOE-2.1 to evaluate project energy savings using IPMVP Option D calibrated simulation methods. CPFilms then enlisted the efforts of Johnson Controls, a leading national energy service company (ESCO), to independently measure and verify energy savings using IPMVP Option C. The Option C measurement of energy savings was compared to predicted savings from the calibrated simulation as a means of determining the suitability of using DOE-2 in predicting energy savings for future projects. This was deemed important, as normally it is not possible to isolate the energy savings from window film installation. Often multiple energy-saving measures are performed along with window film. As a result, Option D typically is the only viable means for determining energy savings from window film installation.

WINDOW FILM ENERGY SAVINGS USING IPMVP OPTION D

Prior to window film installation, a whole-building energy simulation of the demonstration building was prepared.

Fig. 1 Demonstration building following film installation.

To ensure that the simulation model would provide an accurate assessment of the energy savings resulting from window film installation, the monthly and annual energy consumption of the simulated building was compared to the building’s actual consumption for the two previous years. DOE-2 energy analysis software was chosen as the method for simulating the building’s energy performance, based upon the regular use of the program in the research, ESCO, and utility industries as a reliable method for such purposes. Table 2 provides a review of the most pertinent information used in the simulation.

Fig. 2 shows the comparison of monthly and annual electricity consumption for the building using averaged data from 2000 to 2001 compared to the simulation results. As indicated in Fig. 2, the simulation estimate of annual energy use for the demonstration building closely matches actual data for the 2000-2001 period, while matching the monthly fluctuations in energy use reasonably well. As the simulation model uses averaged weather data over multiple years, it is not reasonable to expect simulation and actual monthly energy use to match precisely each month.

Table 1 Window thermal and solar properties

| Window values | U-valuea (Btu/ h/ ft2/deg F) | Solar heat gain coefficient |

| Before film installation | 1.09 | 0.64 |

| After film installation | 0.84 | 0.21 |

| % Improvement with film | 23% | 67% |

“National Fenestration Rating Council (NFRC)/American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) Winter night-time conditions, 0°F outdoors, 15 mph wind, 70°F indoors.

Table 2 Values used in doe-2 simulation

| Building type | Commercial office |

| Building size | 8 floors, 59,000 ft2 total conditioned area |

| Window areas | North—2875 ft2 South—2875 ft2 East—1725 ft2 West—1725 ft2 |

| Window type | Single-pane, 1/4-in., Bronze |

| Lighting offices | 1.0 w/ft2 |

| Plug load | w/ft2 |

| Heating temperatures | 70°F daytime, 65°F night |

| Cooling temperatures | 75°F daytime, 85°F night |

| Ventilation rate | 20 cfm per person, 250 ft2 per person |

| Cooling system efficiency | 1 kW/ton |

Next, the building DOE-2 model was modified to show the effect of adding CPFilms’ LLumar® E-1220 low-e window film to the existing windows. As seen in Table 3, the DOE-2 calculations indicated an 8.4% reduction in annual electricity consumption, saving approximately 180,850 kWh annually and producing a simple payback in 2.77 years.

WINDOW FILM ENERGY SAVINGS USING IPMVP OPTION C

Energy savings for the demonstration building were also independently measured by Johnson Controls using IPMVP Option C, employing the analysis of monthly utility bills. This method was deemed appropriate, as the demonstration building is all electric, making it relatively simple to identify the energy savings from window film installation for both the heating and cooling seasons.

As expected, the main factors causing fluctuations in energy consumption for the building, based on a review of prior energy use, were: (1) building occupancy, and (2) weather conditions. As mentioned, other factors affecting building energy consumption (type and amount of lighting, heating, ventilating and air-conditioning (HVAC) equipment efficiency and type, cooling and heating temperatures, etc.) were held relatively stable to enable isolating the savings from window film installation as much as possible. Accordingly, the method for measuring energy savings would be to determine the energy consumption over the 12-month period prior to window film installation, after adjusting consumption for occupancy and weather, and compare this figure to the value for the 12 months following window film installation.

Fig. 2 Monthly and annual electricity consumption (actual vs DOE-2 model).

Table 3 Annual savings using Option D

| Existing annual electric | 2,153,000 kWh | $138,222 |

| consumption and cost based on average of 2000 & 2001 | ||

| Estimated savings (as a % of existing consumption) | 8.4% | |

| Estimated annual savings Simple payback | 180,850 kWh 2.77 years | $11,610 |

Fig. 3 shows the electricity use per thousand ft2 of occupied space per degree day (kWh/ksqft/DD), before, during and after window film installation. From Fig. 3 it is apparent that during and immediately following window film installation, energy usage began to decrease significantly. As seen in Fig. 4, the average energy consumption for the twelve months prior to film installation was 11.18 kWh/ksqft/DD. Following film installation, the same information was tracked on a monthly basis and the average energy consumption for the twelve months following film installation was 10.19 kWh/ksqft/DD. A comparison of these “before” and “after” values indicated the project’s overall savings to be 8.8%.

Table 4 shows the results obtained from both IPMVP methods, in a side-by-side comparison. As indicated in this table, the results of both methods match closely, giving additional confidence to the results obtained.

Fig. 3 Building energy use—before and after film installation.

Fig. 4 Determining energy savings after film installation.

Table 4 Comparison of energy savings using Option C and Option D

| Option C | Option D | |

| Annual kWh savings Savings as a % of existing | 189,460 8.8% | 180,850 8.4% |

| consumption Annual dollar savings | $12,163 | $11,610 |

| Simple payback (years) | 2.65 | 2.77 |

CONCLUSION

The demonstration project provided insight into the substantial savings that can be achieved from the installation of energy-control window films. The project also demonstrated that significant energy savings can be obtained even in cool climates, if a significant amount of energy-inefficient window glass is utilized on the building envelope. Energy savings in warmer regions are likely to be greater than those shown in this article, but actual savings will be dependent upon many variables, especially existing glass type and type of window film utilized. These variations can easily be accounted for within a DOE-2 analysis for an accurate assessment.

The project also demonstrated that energy savings from window film installation can be accurately predicted using DOE-2 or other appropriate computer simulation software, if an accurate model of the building is prepared. This is especially important, as directly measuring the energy savings from window film installation using IPMVP methods other than Option D is often difficult, as the many factors affecting energy consumption are not normally held constant as they were in this study. Using the information provided by this project, energy savings from future window film projects can be predicted with confidence using DOE-2.