Abstract

This entry discusses a broad range of topics as an overview of the field of wind power. The topics include current penetration, market shares, technology, costs, governments, and regulation.

INTRODUCTION (WEB PREVIEW)

This article is a broad overview of wind power. It covers a range of topics, each of which could be expanded considerably. It is intended as an introductory reference for engineers, students, policy-makers, and the lay public.

Wind power is a small but growing source of electrical energy. Its economics are well known; there are several large and competent manufacturers, and technical problems are steadily being addressed. Wind power can now be considered as a financially and operationally viable alternative when planning additional electrical capacity. However, as shown below, wind power is only a minor component of present energy sources.

World final energy consumption (2002)[1]: 100%

World final electrical consumption (2002)[2]: 16.1%

World final wind power consumption (2004)[3]: 0.15%

Wind power’s main deficiency as a power source is variability. Since wind velocity cannot be controlled or predicted with pinpoint accuracy, alternatives must be available to meet demand fluctuations.

Wind power carries few environmental penalties and makes use of a renewable resource. It has the potential to become a major but not dominant part of the future energy equation.

History

People have used wind to move boats, grind grains, and pump water for thousands of years. Wind-powered flour mills were common in Europe in the 12th century. In the 1700s, the Dutch added technical sophistication to their windmills with improved blades and a method to follow the prevailing wind. Isolated farms in the last century used windmills to generate electricity until the availability of the electrical power grid became widespread.

Past interest in wind power has tended to rise and fall with fuel prices for the predominant method of electrical production—thermal plants burning oil, natural gas, and coal.

CURRENT

Electrical Production

Although small, wind power is a fast-growing part of the energy picture. Since 1990, worldwide installed capacity has grown about 27% (Table 1).[3]

Business is good for the leading manufacturers of wind power devices. Sales have increased; the technology is stable and predictable, with low maintenance and high availability.

Geographical Distribution (Countries)

The European Union had around 72% of installed capacity in 2004, and Germany, Spain, and the United States accounted for 66.1%. Denmark, Spain, and Germany had by far the largest 2004 capacity in terms of MW per million populations, and 10.6% of the world’s population had 81.9% of its wind power capacity. In 2004, Denmark produced about 20% of its electrical power from wind power in 2004 (Table 2).[3]

Manufacturing capacity in 2002 was largely confined to this group of countries, with five big vendors accounting for 76% of sales. European Union vendors accounted for 85% of manufacturing market share.[3]

ECONOMICS Cost per kWh

Wind power is a viable method of producing electricity that is capital intensive with low operating costs. The cost of production compares favorably with traditional fossil fuel or nuclear plant costs.

The major cost elements of a modern wind power installation are as follows [3'5'9]:

Capital

Onshore: 1200-1500 USD/kW Offshore: 1700-2200 USD/kW Operating: usually about 1.5%-2.0% of capital cost per year.[12]

Capital costs include wind capacity survey and analysis, land surveying, permits, roads, foundations, towers and turbines, sensors and communications systems, cabling to transformers and substations, maintenance facilities, testing, and commissioning. By far the largest individual capital cost is the turbine (up to 75%).

Operating and maintenance costs include management fees, insurance, property taxes, rent, and both scheduled and unscheduled maintenance.

Financing costs are a major portion of energy production costs, making them very sensitive to interest rates, incentives and subsidization.

Energy production cost estimates vary considerably. Optimists in the industry, such as the British Wind Energy Association, quote a low of 4.8 USD cents per kWh for an onshore plant in an optimal location. Pessimists, like the Royal Academy of Engineering in the UK, quote up to 13.2 USD cents per kWh for an offshore plant, partly by including a controversial 3.1 USD cents per kWh cost for

Table 2 Capacity distribution

| Country | 2001 | Wind power installed capacity (MW) 2002 2003 | 2004 | One-year (%) | Three-year

(%’) |

Population (millions) | Capacity (MW/Million) | Percent of world capacity | |

| Denmark | 2.456 | 2.880 | 3.076 | 3.083 | 0.2 | 7.9 | 5.4 | 570.9 | 6.4 |

| Spain | 3.550 | 5.043 | 6.420 | 8.263 | 28.7 | 32.5 | 40.3 | 205.0 | 17.2 |

| Germany | 8.734 | 11.968 | 14.612 | 16.649 | 13.9 | 24.0 | 82.4 | 202.1 | 34.7 |

| Netherlands | 523 | 727 | 938 | 1.081 | 15.2 | 27.4 | 16.4 | 65.9 | 2.3 |

| USA | 4.245 | 4.674 | 6.361 | 6.750 | 6.1 | 16.7 | 295.8 | 22.8 | 14.1 |

| Italy | 700 | 806 | 922 | 1.261 | 36.8 | 21.7 | 58.1 | 21.7 | 2.6 |

| UK | 525 | 570 | 759 | 889 | 17.1 | 19.2 | 60.4 | 14.7 | 1.9 |

| Japan | 357 | 486 | 761 | 991 | 30.2 | 40.5 | 127.4 | 7.8 | 2.1 |

| India | 1.456 | 1.702 | 2.125 | 3.000 | 41.2 | 27.2 | 1080.4 | 2.8 | 6.3 |

| China | 406 | 473 | 571 | 769 | 34.7 | 23.7 | 1306.4 | 0.6 | 1.6 |

| Total | 22.952 | 29.329 | 36.545 | 42.736 | 16.9 | 23.0 | 3073 | 89.2 | |

Table 3 Wind power costs

| Wind power costs

Wi RAE [15] |

id onshore

6.8 |

Cents (US)

Wind offshore 9.9 |

per kWh

Coal CFB 4.8 |

Gas CCGT

4.0 |

| RAE 2a | 10.1 | 13.2 | 9.2 | 6.0 |

| EWEA [3] | 5.5 | 8.5 | ||

| AWEA (5) | 6.6 | |||

| AWEA 2b | 5.4 | |||

| BWEA (minimum) [4] | 4.8 | 6.9 | 4.8 | 4.8 |

| BWEA (maximum)0 | 6.8 | 9.1 | 6.8 | 5.9 |

| Euro to USD conversion (2004) | 1.22 | |||

| GBP to USD conversion (2004) | 1.83 |

aAdds 3.1 cents per kWh for wind power backup capacity and 1.9-4.6 cents/kWh for coal and gas carbon capture.

bAWEA figures adjusted to delete 1.8 cents US/kWh production tax credit and are for onshore sites with different average wind speeds.

CBWEA figures for a range of site types in November 2004 and 1-2 cents/kWh for carbon capture.

“standby capacity” required to supply demand when wind power is not available (Table 3).

Capacity Factor

The power generated by a wind turbine depends on the speed of the wind, and on how often it is available. At any given site, this is measured by the capacity factor, or the ratio of actual generated energy to the theoretical maximum. Wind power turbine electrical output rises as the cube of the wind speed. When wind speed doubles, energy output increases eightfold. A typical turbine begins to turn when wind speed is at 9 MPH and will cut out at 56 MPH for safety reasons.

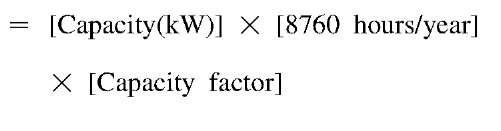

Capacity factors vary by site but are typically in the range of 20%-30% with occasional very good offshore sites reaching 40%. The yearly energy output from a wind farm is given by the following formula:

Output/year( kWh)

The Site

Power production costs, site size, site design, and energy output and variability will depend mainly on details about the wind. These details include wind speed, wind direction, and the geographical distribution of favorable wind profiles. During analysis of potential sites, most planners use high (60 m plus) anemometer towers—often several of them—to gather at least one year’s data per site. These data are usually correlated with national meteorological observations, if these are available and suitable. If not available, it would be prudent to gather site data for a longer period of up to three years.

Investors and regulators are increasingly aware of the crucial nature of wind data in estimating the quantity and timing of potential power production at a specific site. This research is crucial to the financial analysis of a potential wind power venture.

Other site analysis factors are accessibility via road for heavy equipment, electrical grid proximity and capacity, land ownership, and environmental impact.

LOCATION

Favored Geography

Many countries have developed wind charts of broad areas based on meteorological data gathered for weather and aviation purposes. These charts show potential areas for investigation, where wind strength is high and constant over long periods of the year. Once potential sites, and their extent, have been identified, on-site data measurements provide the basis for analysis and modeling of potential energy production for a specific site.

After wind modeling, the site’s geographical, environmental, financing, and ownership issues can be explored in detail.

Generally, sites are either onshore or offshore. Onshore sites are cheaper to construct, but have lower capacity factors due to wind turbulence from nearby hills, trees, and buildings. Offshore sites can have more potential energy available due to higher wind speeds and lower turbulence, which also reduces turbine component wear. Good offshore sites can be near high-demand load areas such as coastal cities, which also increases transmission options. Aesthetic and noise concerns are often fewer offshore, and sea-bed environmental concerns can be lower than land-use concerns for an onshore site.

Sizing a Location

Wind farm towers are usually spread over a large area in order to minimize wake losses. A spacing of five rotor diameters is often recommended. In a typical wind farm, the land physically occupied by tower foundations, buildings, and roads is often less than 2% of overall land area.[6] The remaining land is quite suitable for agriculture and other uses.

Limits to Maximum Production

How much capacity exists to generate electricity from wind? Is it possible that we will require more energy than wind can provide? After surveying wind patterns in the United States and applying energy density and extraction calculations, Elliott and Schwartz[14] concluded in 1993 that 6% of the available U.S. land mass could provide 150% of then-current U.S. electrical consumption. Furthermore, the needed land would be sparsely affected by the wind farm installation, with the vast majority of it (95%-98%) unoccupied by tower foundations, roads, or ancillary equipment and suitable for farming, ranching, and other uses. This study excluded land that is environmentally or otherwise unsuitable, such as cities, forests, parks, wildlife refuges, and environmental exclusion areas.

In the European Union, potential wind power capacity is also larger than current electrical consumption.

FUTURE

Projected Growth

Thanks to increasing concern over the environmental effects of greenhouse gas emissions, the rising cost of fossil fuels, and the impending decrease in availability of oil and natural gas, wind power has a bright future.

Current 25%-30% growth rates are likely not sustainable, due to equipment production volume constraints and limits to perceived need for further capacity. Given the Eurocentric, highly clustered nature of current installed capacity, there is significant potential for high-rate growth elsewhere. However, even in European countries like Germany and Denmark, steady growth will be driven by predicted cost reductions in the 10%-20% range and by regulatory and governmental initiatives aimed at reducing emissions from electrical energy production and transi-tioning to renewable resources.

Projected Cost

Wind power technology is well down the cost improvement curve, with costs having fallen to present levels, below ten cents USD per kWh, from over $1.00 U.S. in 1978. Costs for a medium-sized turbine have dropped 50% since the mid-1980s, reflecting increasing maturity in the market. Cost projections range from a further 9%-17% drop as installed capacity doubles in the near-term future.

Projected Production

With increasing governmental policy support and commitment, growth rates of 15%-20% appear achievable in five to ten years. But there is likely an upper limit to the amount of electrical energy that can be produced from the wind.

Reaching Maximum Production

Production limits for wind power are based on its variable nature. Other types of electrical production capacity will be needed to provide base-load electrical capacity in the event that there is little wind available. Wind power will then become one player in a mix of generating technologies.

The Hydrogen Economy

As wind power becomes a larger portion of electrical supply, occasionally its supply will exceed demand. Rather than simply curtailing wind plant production, it is attractive to think of using this excess electrical power capacity to generate hydrogen via electrolysis. This has the effect of storing wind energy that would otherwise not be harvested. This energy, in the form of hydrogen, can be used directly as a non-polluting fuel or as an input source to fuel cells to produce electricity at a later time.

When there is a significant hydrogen economy, with transmission lines, storage, and fuel cell capacity, this use for wind power will become a very attractive scenario.

Other Issues for the Future

• Learning more about wind and forecasting—predicting the best locations, wind farm output, gusts, and directional shear.[10] This will help reduce financing costs when wind power plant output and impact on the grid are better understood and more predictable.

• Improving the control of demand through incentives around end-user load shedding, rescheduling and simple conservation methods. This could be used to offset wind power production shortfalls as an alternative to other forms of generation.

• Advancing aerodynamics specific to wind turbine blades and control systems.

• Designing extremely large wind tunnels to study wake effects minimization, structural load prediction, and energy output maximization at lower wind speeds.

• Enhancing power system capacity planning models to include wind farm components.

• Re-planting, or upgrading older mechanical and electrical components at existing wind farms.

• Wind farm siting further offshore and on floating platforms.

• Combining wind power and hydroelectric capacity by using surplus wind power to pump water behind dams and so store power that might otherwise be wasted.

• Determining how and whether to allocate full costs of environmental impact to fossil and nuclear plants.

STRENGTHS AND WEAKNESSES

Strengths

Environment

Wind power installations do not emit air pollution in the form of carbon dioxide, sulfur dioxide, nitrogen oxides, or other particulate matter such as heavy metal air toxins. Wind power installations do not use water or discharge any hazardous waste or heat into water. Conventional coal, oil, and gas electric power plants produce significant emissions of all kinds. Nuclear power plants produce dangerous and long-lasting radioactive waste. Greater use of wind power means less impact on health and the environment, particularly regarding climate change due to greenhouse gas emissions.

Renewable

Wind power produces energy from a resource that is constantly renewed. The energy in wind is derived from the sun, which heats different parts of the earth at different rates during the day and over the seasons. Unlike fossil and nuclear plants, the source of energy is essentially inexhaustible.

Costs

Wind power’s costs are well known and are dropping to the point at which this technology is very competitive with other means of production. Fuel costs are nil, meaning that fuel costs have no uncertainty. Wind power costs should be more stable and predictable over the lifetime of the plant than power costs for fossil fuel plants.

Local and Diverse

Wind power plants provide energy source diversity and reduce the need to find, develop, and secure sources of fossil or nuclear fuel. This reduces foreign dependencies in energy supply, and reduces the chances of a political problem or natural disaster interfering with and diminishing the supply of electricity.

Quick to Build, Easy to Expand

Wind power plants of significant capacity can be constructed and installed within a year, a much shorter time than conventional plants. The planning time horizon is similar to conventional plants, given the need to accurately survey site wind characteristics and deal with normal environmental and related site issues. This means that capacity can be increased in closer step with demand than with conventional plants. With the right site and design, a wind power plant can be incrementally expanded very quickly.

Weaknesses

Natural Variability

A single wind farm produces variable amounts of energy, and its output is not yet as predictable as a traditional plant. As the geographical distribution and number of wind plants increases, and as research into predicting wind continues, these problems should be minimized, allowing cost-effective and orderly scheduling and dispatch of total grid capacity sources—but it is difficult to see traditional power sources disappearing entirely.

Connection to Grid

As the amount of electrical power supplied by wind power plants increases, concern increases over its effects on the electrical grid.

In order to maintain a reliable supply of electricity that matches demand, utility operators maintain emergency reserve capacity in order to deal with plant outages (failures) and unexpected demand across their entire system. This reserve is in the form of purchased power, unused capacity at conventional plants running below their maximum, or quick-start plants such as gas-fired turbines. Often, conventional plants on the grid are allocated a cost to cover this reserve based on their capacity (large plant, large reserve) and reliability (more outages, more reserve).

The industry is working on ways to determine and allocate this reserve cost for wind power plants. Yet to be agreed upon is the statistical basis for calculating such wind power plant reserve costs. Improvements in day-ahead wind forecasting will greatly reduce the uncertainty around wind plant output, and so decrease the cost burden to provide this reserve.

Several current estimates prepared for U.S. utilities show this reserve cost burden (or ancillary services cost) to increase with the amount of capacity provided by wind power, and to be in the range of 0.1-0.5 cents USD per kWh for penetrations between 3.5 and 29%. In no case was it thought necessary to allocate a reserve equal to 100% of the wind power capacity.[11] German experience is similar,[8] with no additional reserve capacity required for the 14% wind energy share of the national electrical consumption forecast for 2015.

When wind power supplies less than 20% of electrical consumption, these problems are not severe. At larger penetrations, reserves become a major issue. Interestingly, wind power plants may be subject to shutdown or voluntary power reductions in the event of coincident high wind, low demand situations. This is occasionally the case today in Denmark and Spain.

In some cases, wind power sites are situated far from the location of high electrical power demand, placing strain or potential overload on existing transmission facilities. In these cases, there are often cost, ownership and responsibility issues yet to be resolved.

Power quality problems around power factor, harmonic distortions, and frequency and voltage fluctuations are being successfully addressed in modern large production wind farms.[8]

This is one of the most difficult sets of issues facing the future of wind power as it matures from small-scale and local to large-scale penetration.

Local Resource Shortage

In a few places, high-quality wind power sites are not available or are already in production, leaving these places to import electrical power or use traditional sources.

Noise

Noise levels have decreased and are now confined to blade noise in modern units. Generator and related mechanical noise has been effectively eliminated. Noise, however, will always be a significant factor. Blade noise is described as a “whoosh, whoosh” sound, and is in the 45-50 decibel range at a distance of 200-300 m. This noise level is consistent with many national noise level regulations. However, this noise buffer zone adds to the overall land requirement for a wind power plant and so increases costs.

Visual Impact

Onshore wind farms are highly visible due to the height of towers and the size of the blades and generator. The impact of this varies with each person. Each wind plant operator needs to determine the levels of support and opposition from those who live and work within sight of the plant. Offshore plants attract fewer detractors than onshore plants—one of the reasons for their increasing popularity.

Offshore wind plants are less likely to cause unwanted noise since they are far from human habitation. This reduces turbine and blade design constraints and can lead to higher capacity factors.

Bird Impact

Bird deaths are a regrettable reality. The bird death rate at a specific wind farm project is quite variable. Several early wind farms (Altamont Pass, California, and La Tarifa, Spain) caused concern over death rates. The California Energy Commission estimates the death rate at Altamont (5400 turbines) to be 0.33-0.87 bird deaths per turbine per year.[16] The overall recent U.S. national average[13] is 2.3 bird deaths per turbine per year. Prudently located sites are off migration routes and not in nesting, over-wintering, or feeding areas. Their tower designs do not offer nesting or even roosting places. In such locations, death rates are lower, and overall impact is much lower than that caused by other types of human activity.

Since climate change is a very serious environmental problem faced by bird populations, wind power and other renewables are an important part of the solution.

TECHNOLOGY

Overview

Wind turbine design has three major components, and there are large economies of scale in design.

• Tower height: Wind turbine energy output is proportional to the cube of wind speed. Since moving air (wind) is subject to drag and turbulence from its contact with the earth and the objects on the earth, wind speed increases with height (vertical shear). The higher the tower, the more advantage there is for power generation. The tradeoff is between tower costs and increase in power generation. Typically, tower heights are rising, and are currently in the 100 m range. Off shore, vertical wind shear is generally less than onshore, so towers can be shorter, with wave height clearance being the factor that determines tower height (Fig. 1).

• Blade diameter: The power capacity (watts) of a wind turbine varies with the square of its blade diameter, because a blade with a larger diameter has a larger area available for harvesting the wind energy passing through it. The coefficient of performance defines the actual power capacity compared to the maximum—how much energy can be extracted from the wind compared to the available energy. Modern wind turbines can achieve a coefficient of performance approaching 0.5, very close to the theoretical maximum of 0.59 derived by Betz.[3,18] This maximum is derived from the concept that if 100% of wind energy were extracted, the wind exiting the turbine would be at zero speed, so no new air could enter the turbine. Larger capacity turbines benefit significantly from economies of scale in foundation and support costs as well as swept area (Fig. 2).

Fig. 1 Typical large wind turbine. Note entrance steps and utility pole at base for scale.

• Controls and generating equipment: The turbine’s hub (or nacelle) is the most costly component and contains the generator, gear boxes, yaw controls, brakes, cooling mechanism, computer controls, anemometer, and wind directional vane.

Generators

As the blades turn, they drive a generator to produce electricity. Generating capacity ranges from a few hundred kW to over 3 MW. In older designs, there is usually a 40:1 gearbox to match low, fixed rotor speeds (~ 30 RPM) to required generator speed (1200 RPM for a 60 Hz output, 6-pole generator). The gearbox often incorporates brakes as a part of the overall wind turbine control system. Generators that operate at low RPM are available and are called direct drive generators. These would eliminate the gearbox.

Fig. 2 Site assembly of large wind turbine nacelles and blades.

In more modern designs, rotor speed is variable and controlled to optimize power extraction from the available wind. Generator output is converted to d.c. and then back to a.c. at the required grid frequency and voltage. The conversion equipment is sometimes located at a central part of the wind power plant.

This is an active area for ongoing technical innovation.

Blades

In order to maximize power capacity through size, blades are very long, up to 50 m. To minimize noise, they must turn slowly so as to reduce tip speed, the primary blade noise source. Typical rotation speeds are in the 10-30 RPM range. Blades are increasingly made from composites (carbon fibre reinforced epoxy resins).

Rotor blade aerodynamics[19] have much in common with the aerodynamics of a propeller or a helicopter blade, but they are sufficiently different that the aerodynamics of wind turbine blades is an evolving field. The difference is that wind turbine airflows are unsteady due to gusting, turbulence, vertical shear, turbine tower upstream shadow, yaw correction lag, and the effects of rotation on flow development. For example, at present it can be difficult to predict rotor torque (and therefore power output) accurately for normal turbine operating conditions. Further development of theory and modeling tools should allow the industry to improve rotor strength, weight, power predictability, power output, and plant longevity while controlling cost and structural life.

For a given site wind velocity, the rotor blade’s tip has very different air flow than its root, requiring the blade to be designed in a careful twist. The outer third of the blade generally produces two-thirds of the rotor’s power. The third nearest the hub provides mechanical strength to support the tip, and also provides starting torque in startup situations.

Each blade generally has lightning protection in the form of a metallic piece on the tip and a conductor running to the hub.

Some manufacturers place Whitcomb winglets at the blade tips to reduce induced drag and rotor noise, in common with aircraft wing design.

In order to control blades during high wind speeds, some are designed with a fixed pitch that will progressively stall in high wind speeds. Others incorporate active pitch control mechanisms at the hub. Such control systems use hydraulic actuators or electric stepper motors and must act very quickly to be effective.

Wind Sensors

Wind turbines incorporate an anemometer to measure wind speed and one or more vanes to measure direction. These are primary inputs to the control mechanism and data gathering systems usually incorporated into a wind turbine.

Control Mechanisms (Computer Systems)

Control systems are used to yaw the wind turbine to face into the wind, and in some designs to control blade pitch angle or activate brakes when wind gets too strong. In sophisticated cases, the controllers are redundant closed-loop systems that operate pumps, valves and motors to achieve optimum wind turbine performance. They also monitor and collect data about wind strength and direction; electrical voltage, frequency and current; nacelle and bearing temperatures; hydraulic pressure levels; and rotor speeds, vibration, yaw, fluid levels, and blade pitch angle. Some designs provide warnings and alarms to central site operators via landline or radio. Manufacturers do not release much detail about these systems, since they are a critical contributor to a wind turbine’s overall effectiveness, safety, and mechanical longevity.

ROLE OF GOVERNMENTS AND REGULATORS

Governments play a large part in determining the role and scale of wind energy in our future mix of energy production capabilities.

Subsidies, Tax Incentives

As part of programs to encourage wind power production, the following are used in varying ways[7]:

• Outright subsidies, grants and no-interest loans.

• Tax incentives such as accelerated depreciation.

• Fixed prices paid for produced electrical power.

• Renewable energy quantity targets imposed on power utility operators.

Grid Interconnection and Regulatory Issues

Since many power utility operators are owned by governments, and most are regulated heavily, governments have a role to play in encouraging solutions to grid interconnection issues. There must be a political will to address issues, find solutions, and develop practices and different management strategies that will allow greater penetration of wind power into the electrical supply.

Improving Wind Information

Climate and environmental information is most often collected and supplied by national governments in support of weather and aviation services. Wind atlases are an invaluable resource to the wind plant planning process. National efforts to improve long- and short-term wind forecasting, atmospheric modeling tools, and techniques will benefit wind power projects’ ability to forecast power output for long-term and short-term planning purposes.[10]

Environmental Regulation

In this controversial area, government can tighten its regulation of air quality, carbon emissions and other environmental areas. This would have the effect of increasing the apparent cost of conventional thermal electrical power, which is responsible for significant emissions. It is often argued that wind power would already be cost competitive if environmental and health costs were to be fully allocated to conventional oil, gas, and particularly coal-powered plants, or if such plants were required to make investments to significantly reduce emissions.

CONCLUSION

Western societies depend on a steady supply of energy, much of it in the form of electricity. Most of that supply comes from thermal plants that burn oil, natural gas, and coal, or from nuclear plants. Where will our electrical energy come from in the future? How will we keep our environment livable and healthy?

One part of this answer lies in wind power. Its costs are within reason; the technology has matured with some gains yet to be realized; it carries little environmental penalty; and the source of its energy is renewable. As long as the sun heats the earth, wind power will be available.

Wind power will not likely be the complete answer; it is an intermittent source because the wind doesn’t always blow. But there is a very large amount of it available for us to harvest. As wind power moves quickly from small-scale to large-scale, its future path depends on governments and regulators as much as it does on technical innovators and manufacturers.