5.2.10

As discussed, stepping motors come in two varieties, permanent magnet and variable reluctance (hybrid motors are indistinguishable from PM motors from the controller’s point of view). Lacking a label on the motor, you can generally tell the two apart by feel when no power is applied. PM motors tend to cog as you twist the rotor with your fingers, while VR motors almost spin freely (although they may cog slightly because of residual magnetization in the rotor). You can also distinguish between the two varieties with an ohmmeter. VR motors usually have three (sometimes four) windings, with a common return, while PM motors usually have two independent windings, with or without center taps. Center-tapped windings are used in unipolar PM motors.

Stepping motors come in a wide range of angular resolutions. The coarsest motors typically turn 90° per step, while high-resolution PM motors are commonly able to handle 1.8° or even 0.72° per step. With an appropriate controller, most PM and hybrid motors can be run in half-steps, and some controllers can handle smaller fractional steps or microsteps.

For both PM and VR stepping motors, if just one winding of the motor is energized, the rotor (under no load) will snap to a fixed angle and then hold that angle until the torque exceeds the holding torque of the motor, at which point the rotor will turn, trying to hold at each successive equilibrium point.

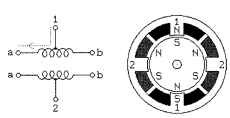

VR Motors. If your motor has three windings, typically connected as shown in the schematic diagram in Fig. 5.85, with one terminal common to all windings, it is most likely a VR stepping motor. In use, the common wire typically goes to the positive supply, and the windings are energized in sequence.

Figure 5.85 shows a cross section of a 30°-per-step VR motor. The rotor in this motor has four teeth and the stator has six poles, with each winding wrapped around two opposite poles. With winding 1 energized, the rotor teeth marked X are attracted to this winding’s poles. If the current through winding 1 is turned off and winding 2 is turned on, the rotor will rotate 30° degrees clockwise so that the poles marked Y line up with the poles marked 2.

FIGURE 5.85 Variable-reluctance connection diagram.

To rotate this motor continuously, we just apply power to the three windings in sequence. Assuming positive logic, where 1 means turning on the current through a motor winding, the following control sequence will spin the motor illustrated in Fig. 5.85 clockwise 24 steps or 2 revolutions:

The section on midlevel control in Chap. 10 provides details on methods for generating such sequences of control signals, while the section on control circuits (Sec. 10.8) discusses the power switching circuitry needed to drive the motor windings from such control sequences. There are also VR stepping motors with four and five windings, requiring five or six wires. The principle for driving these motors is the same as that for the three-winding variety, but it becomes important to work out the correct order to energize the windings to make the motor step nicely.

The motor geometry illustrated in Fig. 5.85, giving 30° per step, uses the fewest number of rotor teeth and stator poles that perform satisfactorily. Using more motor poles and more rotor teeth allows construction of motors with smaller step angles. Toothed faces on each pole and a correspondingly finely toothed rotor allow for step angles as small as a few degrees.

Unipolar Motors. Unipolar stepping motors, both PM and hybrid stepping motors with five or six wires, are usually wired as shown in the schematic in Fig. 5.86, with a center tap on each of two windings. In use, the center taps of the windings are typically wired to the positive supply, and the two ends of each winding are alternately grounded to reverse the direction of the field provided by that winding.

FIGURE 5.86 Unipolar motor.

Figure 5.86 shows a cross section of a 30°-per-step PM or hybrid motor—the difference between these two motor types is not relevant at this level of abstraction. Motor winding 1 is distributed between the top and bottom stator pole, while motor winding 2 is distributed between the left and right motor poles. The rotor is a permanent magnet with six poles, three south and three north, arranged around its circumference.

For higher angular resolutions, the rotor must have proportionally more poles. The 30°-per-step motor in Fig. 5.86 is one of the most common PM motor designs, although 15°- and 7.5°-per-step motors are widely available. PM motors with resolutions as good as 1.8° per step are made, and hybrid motors are routinely built with 3.6° and 1.8° per step, with resolutions as fine as 0.72° per step available.

As shown in Fig. 5.86, the current flowing from the center tap of winding 1 to terminal a causes the top stator pole to be a north pole while the bottom stator pole is a south pole. This attracts the rotor into the position shown. If the power to winding 1 is removed and winding 2 is energized, the rotor will turn 30°, or one step.

To rotate the motor continuously, we just apply power to the two windings in sequence. Assuming positive logic, where 1 means turning on the current through a motor winding, the following two control sequences will spin the motor illustrated in Fig. 5.86 clockwise 24 steps or 4 revolutions:

Note that the two halves of each winding are never energized at the same time. Both sequences shown will rotate a permanent magnet one step at a time. The top sequence powers only one winding at a time, as illustrated in Fig. 5.86; thus, it uses less power. The bottom sequence involves powering two windings at a time and generally produces a torque about 1.4 times greater than the top sequence while using twice as much power.

The section on midlevel control in Chap. 10 provides details on methods for generating such sequences of control signals, while the section on control circuits (Sec. 10.8) discusses the power switching circuitry needed to drive the motor windings from such control sequences.

The step positions produced by the two preceding sequences are not the same; as a result, combining the two sequences allows half-stepping, with the motor stopping alternately at the positions indicated by one or the other sequence. The combined sequence is as follows:

Bipolar Motors. Bipolar PM and hybrid motors are constructed with exactly the same mechanism as is used on unipolar motors, but the two windings are wired more simply, with no center taps. Thus, the motor itself is simpler, but the drive circuitry needed to reverse the polarity of each pair of motor poles is more complex. The schematic in Fig. 5.87 shows how such a motor is wired, while the motor cross section shown here is exactly the same as the cross section shown in Fig. 5.87.

FIGURE 5.87 Bipolar motor.

The drive circuitry for such a motor requires an H-bridge control circuit for each winding; these are discussed in more detail in Sec. 10.8. Briefly, an H bridge allows the polarity of the power applied to each end of each winding to be controlled independently. The control sequences for single stepping such a motor are shown here, using + and – symbols to indicate the polarity of the power applied to each motor terminal:

Note that these sequences are identical to those for a unipolar permanent magnet motor, at an abstract level, and that above the level of the H-bridge power-switching electronics, the control systems for the two types of motor can be identical.

Note that many full H-bridge driver chips have one control input to enable the output and another to control the direction. Given two such bridge chips, one for winding, the following control sequences will spin the motor identically to the control sequences given previously:

To distinguish a bipolar PM motor from other four-wire motors, measure the resistances between the different terminals. It is worth noting that some PM stepping motors have four independent windings, organized as two sets of two. Within each set, if the two windings are wired in series, the result can be used as a high-voltage bipolar motor. If they are wired in parallel, the result can be used as a low-

voltage bipolar motor. If they are wired in series with a center tap, the result can be used as a low-voltage unipolar motor.

Multiphase Motors. A less common class of PM stepping motor is wired with all windings of the motor in a cyclic series, with one tap between each pair of windings in the cycle. The most common designs in this category use three-phase and five-phase wiring. The control requires half of an H bridge for each motor terminal, but these motors can provide more torque from a given package size because all or all but one of the motor windings are energized at every point in the drive cycle. Some 5-phase motors have high resolutions on the order of 0.72° per step (500 steps per revolution).

With a 5-phase motor, there are 10 steps per repeat in the stepping cycle, as shown here:

Here, as in the bipolar case, each terminal is shown as being connected to either the positive or negative bus of the motor power system. Note that at each step, only one terminal changes polarity. This change removes the power from one winding attached to that terminal (because both terminals of the winding in question are of the same polarity) and applies power to one winding that was previously idle. Given the motor geometry suggested by Fig. 5.88, this control sequence will drive the motor through two revolutions.

FIGURE 5.88 Multiphase motor

To distinguish a five-phase motor from other motors with five leads, note that if the resistance between two consecutive terminals of the five-phase motor is R, the resistance between non-consecutive terminals will be 1.5R.

Note that some 5-phase motors have 5 separate motor windings, with a total of 10 leads. These can be connected in the star configuration shown in Fig. 5.88, using five half-bridge driver circuits, or each winding can be driven by its own

full bridge. While the theoretical component count of half-bridge drivers is lower, the availability of integrated full-bridge chips may make the latter approach preferable.

Stepping-Motor Physics. In any presentation covering the quantitative physics of a class of systems, it is important to be aware of the units of measurement used. This presentation of stepping-motor physics assumes standard physical units, as outlined

in Table 5.22.

A force of 1 lb will accelerate a mass of 1 slug at 1 ft/s2. The same relationship holds between the force, mass, time, and distance units of the other measurement systems. Most people prefer to measure angles in degrees, and the common engineering practice of specifying mass in pounds or force in kilograms will not yield correct results in the formulas given here. Care must be taken to convert such irregular

TABLE 5.22 Standard Physical Units

| Measurement | System | ||

| English | CGS | MKS | |

| Mass | Slug | Gram (g) | Kilogram (kg) |

| Force | Pound (lb) | Dyne (dyn) | Newton (N) |

| Distance | Foot (ft) | Centimeter (cm) | Meter (m) |

| Time | Second (s) | Second (s) | Second (s) |

| Angle | Radian (rad) | Radian (rad) | Radian (rad) |

units to one of the standard systems outlined in Table 5.22 before applying the formulas given here.

Statics. For a motor that turns S rad per step, the plot of torque versus angular position for the rotor relative to some initial equilibrium position will generally approximate a sinusoid. The actual shape of the curve depends on the pole geometry of both rotor and stator, and neither this curve nor the geometry information is given in the motor data sheets this author has seen. For PM and hybrid motors, the actual curve usually looks sinusoidal, but looks can be misleading. For VR motors, the curve rarely even looks sinusoidal; trapezoidal and even asymmetrical sawtooth curves are not uncommon.

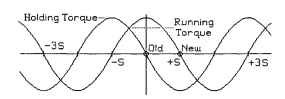

For a three-winding VR or PM motor with S rad per step, the period of the torque versus position curve will be 3S; for a five-phase PM motor, the period will be 5S. For a two-winding PM or hybrid motor, the most common type, the period will be 4S, as illustrated in Fig. 5.89.

FIGURE 5.89 Holding torque versus rotor position.

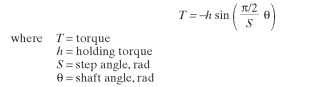

Again, for an ideal two-winding PM motor, this can be mathematically expressed as follows:

But remember, subtle departures from the ideal sinusoid described here are very common. The single-winding holding torque of a stepping motor is the peak value of the torque versus position curve when the maximum allowed current is flowing through one motor winding. If you attempt to apply a torque greater than this to the motor rotor while maintaining power to one winding, it will rotate freely.

It is sometimes useful to distinguish between the electrical shaft angle and the mechanical shaft angle. In the mechanical frame of reference, 2 rad is defined as one full revolution. In the electrical frame of reference, a revolution is defined as one period of the torque versus shaft-angle curve.Throughout this subsection, 6 refers to the mechanical shaft angle, and (n/2)/S gives the electrical angle for a motor with 4 steps per cycle of the torque curve.

Assuming that the torque versus angular-position curve is a good approximation of a sinusoid, as long as the torque remains below the holding torque of the motor, the rotor will remain within ^ period of the equilibrium position. For a two-winding PM or hybrid motor, this means the rotor will remain within one step of the equilibrium position. With no power to any of the motor windings, the torque does not always fall to zero. In VR stepping motors, residual magnetization in the magnetic circuits of the motor may lead to a small residual torque, and in PM and hybrid stepping motors, the combination of pole geometry and the permanently magnetized rotor may lead to significant torque with no applied power.

The residual torque in a PM or hybrid stepping motor is frequently referred to as the cogging torque or detent torque of the motor because a naive observer will frequently guess that there is a detent mechanism of some kind inside the motor. The most common motor designs yield a detent torque that varies sinusoidally with rotor angle, with an equilibrium position at every step and an amplitude of roughly 10 percent of the rated holding torque of the motor, but a quick survey of motors from one manufacturer (Phytron) shows values as high as 23 percent for one very small motor to a low of 2.6 percent for one midsized motor.

Half-Stepping and Microstepping. So long as no part of the magnetic circuit saturates, powering two motor windings simultaneously will produce a torque versus position curve that is the sum of the torque versus position curves for the two motor windings taken in isolation. For a two-winding PM or hybrid motor, the two curves will be S rad out of phase, and if the currents in the two windings are equal, the peaks and valleys of the sum will be displaced S/2 rad from the peaks of the original curves, as shown in Fig. 5.90.

FIGURE 5.90 Holding torque versus rotor position, one and two phases on.

This is the basis of half-stepping. The two-winding holding torque is the peak of the composite torque curve when two windings are carrying their maximum rated current. For common two-winding PM or hybrid stepping motors, the two-winding holding torque is

This assumes that no part of the magnetic circuit is saturated and that the torque versus position curve for each winding is an ideal sinusoid.

Most PM and VR stepping-motor data sheets quote the two-winding holding torque and not the single-winding figure; in part, this is because it is larger, and in part, it is because the most common full-step controllers always apply power to two windings at once.

If any part of the motor’s magnetic circuits is saturated, the two torque curves will not add linearly. As a result, the composite torque will be less than the sum of the component torques, and the equilibrium position of the composite may not be exactly S/2 rad from the equilibria of the original.

Microstepping allows even smaller steps by using different currents through the two motor windings, as shown in Fig. 5.91.

FIGURE 5.91 Relative holding-torque position under microstep control.

For a two-winding VR or PM motor, assuming nonsaturating magnetic circuits, and assuming perfectly sinusoidal torque versus position curves for each motor winding, the following formula gives the key characteristics of the composite torque curve:

In the absence of saturation, the torques a and b are directly proportional to the currents through the corresponding windings. It is quite common to work with normalized currents and torques, so that the single-winding holding torque or the maximum current allowed in one motor winding is 1.0.

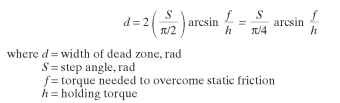

Friction and the Dead Zone. The torque versus position curve shown in Fig. 5.89 does not take into account the torque the motor must exert to overcome friction. Note that frictional forces may be divided into two large categories, static or sliding friction, which requires a constant torque to overcome, regardless of velocity, and dynamic friction or viscous drag, which offers a resistance that varies with velocity. Here, we are concerned with the impact of static friction. Suppose the torque needed to overcome the static friction on the driven system is half the peak torque of the motor, as illustrated in Fig. 5.92.

FIGURE 5.92 Holding torque versus rotor position showing relative static friction.

The dotted lines in Fig. 5.92 show the torque needed to overcome friction; only that part of the torque curve outside the dotted lines is available to move the rotor. The curve showing the available torque as a function of the shaft angle is the difference between these curves, as shown in Fig. 5.93.

FIGURE 5.93 Curve of available torque once friction torque is removed.

Note that the consequences of static friction are twofold. First, the total torque available to move the load is reduced; second, there is a dead zone about each of the equilibria of the ideal motor. If the motor rotor is positioned anywhere within the dead zone for the current equilibrium position, the frictional torque will exceed the torque applied by the motor windings, and the rotor will not move. Assuming an ideal sinusoidal torque versus position curve in the absence of friction, the angular width of these dead zones is

The important thing to note about the dead zone is that it limits the ultimate positioning accuracy. For the example, where the static friction is half the peak torque, a 90°-per-step motor will have dead zones 60° wide. This means that successive steps may be as large as 150° and as small as 30°, depending on where in the dead zone the rotor stops after each step.

The presence of a dead zone has a significant impact on the utility of microstep-ping. If the dead zone is 70° wide, then microstepping with a step size smaller than 70° may not move the rotor at all. Thus, for systems intended to use high-resolution microstepping, it is very important to minimize static friction.

Dynamics. Each time you step the motor, you electronically move the equilibrium position S rad. This moves the entire curve illustrated in Fig. 5.89 a distance of S rad, as shown in Fig. 5.94.

The first thing to note about the process of taking one step is that the maximum available torque is at a minimum when the rotor is halfway from one step to the next. This minimum determines the running torque, the maximum torque the motor can drive as it steps slowly forward. For common two-winding PM motors with ideal sinusoidal torque versus position curves and holding torque h, this will be h/(20.5). If the motor is stepped by powering two windings at a time, the running torque of an ideal two-winding PM motor will be the same as the single-winding holding torque.

FIGURE 5.94 Holding-torque curves showing maximum torque when moved S rad.

It should be noted that at higher stepping speeds, the running torque is sometimes defined as the pull-out torque. That is, it is the maximum frictional torque the motor can overcome on a rotating load before the load is pulled out of step by the friction. Some motor data sheets define a second torque figure, the pull-in torque. This is the maximum frictional torque that the motor can overcome to accelerate a stopped load to synchronous speed. The pull-in torques documented on stepping-motor data sheets are of questionable value, because the pull-in torque depends on the moment of inertia of the load used when it is measured, and few motor data sheets document this.

In practice, there is always some friction, so after the equilibrium position moves one step, the rotor is likely to oscillate briefly about the new equilibrium position. The resulting trajectory may resemble the one shown in Fig. 5.95. Here, the trajectory of the equilibrium position is shown as a dotted line, while the solid curve shows the trajectory of the motor rotor.

Resonance. The resonant frequency of the motor rotor depends on the amplitude of the oscillation; but as the amplitude decreases, the resonant frequency rises to a

FIGURE 5.95 Trajectory of rotor oscillation.

well-defined small-amplitude frequency. This frequency depends on the step angle and on the ratio of the holding torque to the moment of inertia of the rotor. Either a higher torque or a lower moment will increase the frequency.

Formally, the small-amplitude resonance can be computed as follows. First, recall Newton’s law for angular acceleration:

T = |i A

where T = torque applied to rotor

\i = moment of inertia of rotor and load A = angular acceleration, rad/s2

Assume that, for small amplitudes, the torque on the rotor can be approximated as a linear function of the displacement from the equilibrium position. Therefore, Hooke’s law applies:

It is crucial to note that it is the moment of inertia of the rotor plus any coupled load that matters. The moment of the rotor, in isolation, is irrelevant. Some motor data sheets include information on resonance, but if any load is coupled to the rotor, the resonant frequency will change.

In practice, this oscillation can cause significant problems when the stepping rate is anywhere near a resonant frequency of the system; the result frequently appears as random and uncontrollable motion.

Resonance and the Ideal Motor. Up to this point, the discussion has dealt only with the small-angle spring constant k for the system. This can be measured experimentally, but if the motor’s torque versus position curve is sinusoidal, it is also a simple function of the motor’s holding torque. Recall that:

Given that the holding torque and resonant frequency of the system are easily measured, the easiest way to determine the moment of inertia of the moving parts in a system driven by a stepping motor is indirectly from the preceding relationship.

![]()

For practical purposes, it is usually not the torque or the moment of inertia that matters, but rather the maximum sustainable acceleration. Conveniently, this is a simple function of the resonant frequency. Starting with the Newton’s law for angular acceleration:

![]()

You can substitute this formula for the moment of inertia as a function of resonant frequency, and then substitute the maximum sustainable running torque as a function of the holding torque to get:

![]()

Measuring acceleration in steps per second squared instead of in radians per second squared, this simplifies to

![]()

Thus, for an ideal motor with a sinusoidal torque versus rotor position function, the maximum acceleration in steps per second squared is a trivial function of the resonant frequency of the motor and rigidly coupled load.

For a two-winding PM or VR motor, with an ideal sinusoidal torque versus position characteristic, the two-winding holding torque is a simple function of the single-winding holding torque:

This relationship holds only if the torque provided by the motor does not vary appreciably as the stepping rate varies between these two frequencies.

In general, as discussed later, the available torque will tend to remain relatively constant up until some cutoff stepping rate, and then it will fall. Therefore, this relationship holds only if the resonant frequencies are below this cutoff stepping rate. At stepping rates above the cutoff rate, the two frequencies will be closer to each other.

Living with Resonance. If a rigidly mounted stepping motor is rigidly coupled to a frictionless load and then stepped at a frequency near the resonant frequency, energy will be pumped into the resonant system, and the result of this is that the motor will literally lose control. There are three basic ways to deal with this problem.

Controlling Resonance in the Mechanism. Use of elastomeric motor mounts or elastomeric couplings between motor and load can drain energy out of the resonant system, preventing energy from accumulating to the extent that it allows the motor rotor to escape from control.

Or, viscous damping can be used. Here, the damping will not only draw energy out of the resonant modes of the system, it will also subtract from the total torque available at higher speeds. Magnetic eddy current damping is equivalent to viscous damping for our purposes.

Figure 5.96 illustrates the use of elastomeric couplings and viscous damping in two typical stepping-motor applications, one using a lead screw to drive a load, and the other using a tendon drive.

FIGURE 5.96 Damping in step-motor systems.

Elastomeric motor mounts are shown at a and elastomeric couplings between the motor and load are shown at b and c. The end bearing for the lead screw or tendon, at d, offers an opportunity for viscous damping, as do the ways on which the load slides, at e. Even the friction found in sealed ball bearings or Teflon on steel ways can provide enough damping to prevent resonance problems.

Controlling Resonance in the Low-Level Drive Circuitry. A resonating motor rotor will induce an alternating current voltage in the motor windings. If some motor winding is not currently being driven, shorting this winding will impose a drag on the motor rotor that is exactly equivalent to using a magnetic eddy current damper.

If some motor winding is currently being driven, the ac voltage induced by the resonance will tend to modulate the current through the winding. Clamping the motor current with an external inductor will counteract the resonance. Schemes based on this idea are incorporated into some of the drive circuits illustrated in later sections of this handtopic.

Controlling Resonance in the High-Level Control System. The high-level control system can avoid driving the motor at known resonant frequencies, accelerating and decelerating through these frequencies and never attempting sustained rotation at these speeds.

Recall that the resonant frequency of a motor in half-stepped mode will vary by up to 20 percent from one half-step to the next. As a result, half-stepping pumps energy into the resonant system less efficiently than full stepping. Furthermore, when operating near these resonant frequencies, the motor control system may preferentially use only the two-winding half steps when operating near the single-winding resonant frequency, and only the single-winding half steps when operating near the two-winding resonant frequency. Figure 5.97 illustrates this.

The darkened curve in Fig. 5.97 shows the operating torque achieved by a simple control scheme that delivers useful torque over a wide range of speeds despite the fact that the available torque drops to zero at each resonance in the system. This solution is particularly effective if the resonant frequencies are sharply defined and well separated. This is the case in minimally damped systems operating well below the cutoff speed defined in the next subsection.

FIGURE 5.97 Variation of resonant speed based on winding excitation.

Torque Versus Speed. An important consideration in designing high-speed stepping-motor controllers is the effect of the inductance of the motor windings. As with the torque versus angular-position information, this is frequently poorly documented in motor data sheets; indeed, for VR stepping motors, it is not a constant. The inductance of the motor winding determines the rise and fall time of the current through the windings. While one might hope for a square-wave plot of current versus time, the inductance forces an exponential, as illustrated in Fig. 5.98.

FIGURE 5.98 Effect of inductance on torque.

The details of the current versus time function through each winding depend as much on the drive circuitry as they do on the motor itself. It is quite common for the time constants of these exponentials to differ. The rise time is determined by the drive voltage and drive circuitry, while the fall time depends on the circuitry used to dissipate the stored energy in the motor winding.

At low stepping rates, the rise and fall times of the current through the motor

windings has little effect on the motor’s performance, but at higher speeds, the effect of the inductance of the motor windings is to reduce the available torque, as shown

in Fig. 5.99.

FIGURE 5.99 Reduction of torque at higher speeds caused by inductance.

The motor’s maximum speed is defined as the speed at which the available torque falls to zero. Measuring maximum speed can be difficult when there are resonance problems, because these cause the torque to drop to zero prematurely. The cutoff speed is the speed above which the torque begins to fall. When the motor is operating below its cutoff speed, the rise and fall times of the current through the motor windings occupy an insignificant fraction of each step, while at the cutoff speed, the step duration is comparable to the sum of the rise and fall times. Note that a sharp cutoff is rare; therefore, statements of a motor’s cutoff speed are, of necessity, approximate.

The details of the torque versus speed relationship depend on the details of the rise and fall times in the motor windings, and these depend on the motor control system as well as the motor. Therefore, the cutoff speed and maximum speed for any

particular motor depend, in part, on the control system. The torque versus speed curves published in motor data sheets occasionally come with documentation on the motor controller used to obtain those curves, but this is far from universal practice.

Similarly, the resonant speed depends on the moment of inertia of the entire rotating system, not just the motor rotor, and the extent to which the torque drops at resonance depends on the presence of mechanical damping and on the nature of the control system. Some published torque versus speed curves show very clear resonances without documenting the moment of inertia of the hardware that may have been attached to the motor shaft in order to make torque measurements.

The torque versus speed curve shown in Fig. 5.99 is typical of the simplest of control systems. More complex control systems sometimes introduce electronic resonances that act to increase the available torque above the motor’s low-speed torque. A common result of this is a peak in the available torque near the cutoff speed.

Electromagnetic Issues. In a PM or hybrid stepping motor, the magnetic field of the motor rotor changes with changes in shaft angle. The result of this is that turning the motor rotor induces an ac voltage in each motor winding. This is referred to as the counter-emf because the voltage induced in each motor winding is always in phase with and counter to the ideal waveform required to turn the motor in the same direction. Both the frequency and amplitude of the counter-emf increase with rotor speed; therefore, counter-emf contributes to the decline in torque with increased stepping rate.

VR stepping motors also induce counter-emf. This is because the reluctance of the magnetic circuit declines as the stator winding pulls a tooth of the rotor toward its equilibrium position. This decline increases the inductance of the stator winding, and this change in inductance demands a decrease in the current through the winding in order to conserve energy. This decrease is evidenced as a counter-emf.

The reactance (inductance and resistance) of the motor windings limits the current flowing through them. Thus, by Ohm’s law, increasing the voltage increases the current, and therefore increases the available torque. The increased voltage also serves to overcome the counter-emf induced in the motor windings, but the voltage cannot be increased arbitrarily. Thermal, magnetic, and electronic considerations all serve to limit the useful torque that a motor can produce.

The heat given off by the motor windings is due to simple resistive losses, eddy current losses, and hysteresis losses. If this heat is not conducted away from the motor adequately, the motor windings will overheat. The simplest failure this can cause is insulation breakdown, but it can also heat a permanent magnet rotor above its Curie temperature, resulting in loss of magnetization. This is a particular risk with many modern high-strength magnetic alloys.

Even if the motor is attached to an adequate heat sink, increased drive voltage will not necessarily lead to increased torque. Most motors are designed so that the magnetic circuits of the motor are near saturation at the rated current flow through the windings. Increased current will not lead to an appreciably increased magnetic field in such a motor.

Given a drive system that limits the current through each motor winding to the rated maximum for that winding, but uses high voltages to achieve a higher cutoff torque and higher torques above cutoff, there are other limits that come into play. At high speeds, the motor windings must, of necessity, carry high-frequency ac signals. This leads to eddy current losses in the magnetic circuits of the motor, and it leads to skin-effect losses in the motor windings.

Motors designed for very high speed running should, therefore, have magnetic structures using very thin laminations or even nonconductive ferrite materials, and they should have small-gauge wire in their windings to minimize skin-effect losses.

Common high-torque motors have large-gauge motor windings and coarse core laminations. At high speeds, such motors can easily overheat, and they should therefore be derated accordingly for high-speed running.

It is also worth noting that the one way to demagnetize something is to expose it to a high-frequency high-amplitude magnetic field. Running the control system to spin the rotor at high speed when the rotor is actually stalled, or spinning the rotor at high speed against a control system trying to hold the rotor in a fixed position, will expose the rotor to a high-amplitude high-frequency field. If such operating conditions are common—particularly if the motor is run near the Curie temperature of the permanent magnets—demagnetization is a serious risk, and the field strengths (and expected torques) should be reduced accordingly.