7.5

A wide variety of loads can be considered constant-torque loads. Conveyers are probably the most common type of constant-torque application. The means of achieving adjustable speed for these types of loads has been basically mechanical methods or DC drives. The adjustable-frequency induction motor drive systems add a new dimension to the method of adjusting the output speed for such loads.

A comparison of the annual power costs for the following adjustable-speed drive systems driving a constant-torque load is made in the following example:

Eddy current or hydrodynamic drives Mechanical adjustable-speed drives Adjustable-frequency induction motor drives

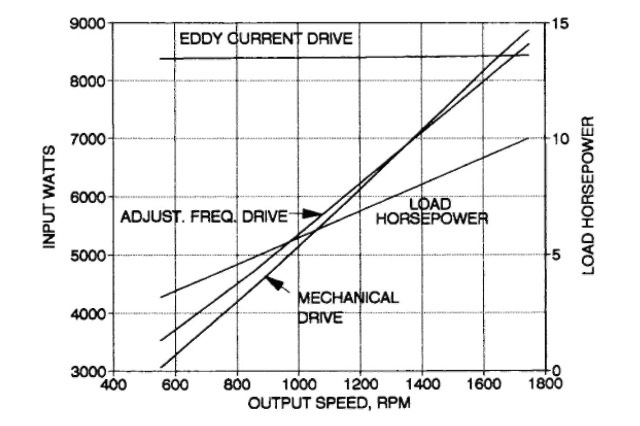

FIGURE 7.61 Input watts for a constant-torque load with various adjustable-speed drive systems.

TABLE 7.6 Annual Power Costs for Example Constant-Torque Conveyer Drive Systems

| Annual energy | ||

| consumption, | Annual power | |

| System | kWh | cost, $ |

| Eddy current drive | 16,817 | 1,008.99 |

| Mechanical | 14,649 | 878.94 |

| adjustable-speed drive | ||

| Adjustable-frequency drive | 14,544 | 872.64 |

Figure 7.61 shows the input power and load horsepower for each of the above drive systems over the speed range considered. The input power is based on a 10-hp, 1800-rpm energy-efficient drive motor for each system and the efficiency of each system.

Based on these data, the annual power consumption in kilowatt-hours and the power cost in dollars for each of the above systems are shown in Table 7.6. With the narrow range in annual power cost, additional factors such as initial cost, ease in operation, remote control features, environment, and maintenance must be considered in selecting the proper adjustable-speed drive system for a constant-torque load.