…

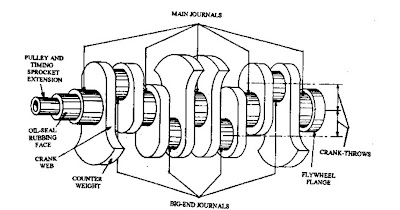

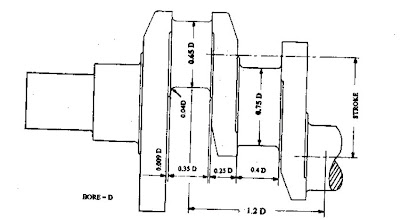

Crankshafts normally have either integral (Fig. 3.63) or attachable (Fig. 3.64) counterweights. These counterweights counteract the centrifugal force created by each individual crankpin and its webs as the whole crankshaft is rotated about the main-journal axis. In absence of the counterweights, the crankpin masses tend to bend and distort the crankshaft causing excessive edge-loading in the main bearings. Therefore, each half crank-web is generally extended in the opposite direction to that of the crankpin, to counterbalance the effects of the crankpin.

Integral crankshaft.

Attached crankshaft.

Bolt-on counterweights are, sometimes, used for large in-line and *V engines (Fig. 3.64) because of the simplicity in casting or forging the crankshaft. The use of detachable weights allows their slight overlap on the webs and this increase in web width permits concentration of more mass at a smaller radius from the axis of rotation. The attaching weights to the web is to be located and attached very accurately, otherwise any error in assembly results in an unbalanced crankshaft.