32.7.

Engine Power

The power delivered by the engine is transmitted down the drive-line of the vehicle to be translated into a propulsive force at the drive wheels. It is essential, therefore, for vehicle performance calculations that the engine characteristics are known in some detail. These are usually obtained by placing the vehicle itself on a chassis dynamometer. Alternatively, the engine may be removed from the vehicle and placed on a test bed in the laboratory where more precise measurement may be made. A chassis dynamometer has the obvious advantage of convenience that the torque measured is at the drive wheels. However, it is not so easy to control conditions when using a chassis dynamometer and the distortion of the drive wheel tyres can introduce problems. It is more usual, therefore, to use an engine test bed for the determination of engine characteristics.

The measurements so obtained are usually the steady state characteristics of the vehicle. They do not include transient effects such as the change in torque and fuel consumption produced by an accelerating engine. Such changes from the steady state measurements may result in small differences in the fuel and air flow rates into the engine and hence in the power output. Also a difference is caused by the engine having to accelerate its own inertia. This difference may be large but it is easy to modify the steady state results to take this into account. The other transient effects are difficult to accommodate and since they are small, it is usual to ignore them.

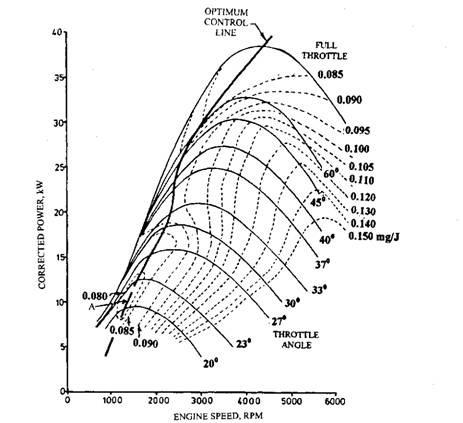

In addition to torque and speed measurements, the other engine quantity which may require to be measured for vehicle performance is the steady state fuel consumption. It is important that the engine under test be in full vehicle trim if meaningful vehicle performance calculations are to result. The engine must have its normal air cleaner system and be driving all its usual accessories, such as fan, water pump, charging alternator, oil pump etc. It is important also, although not always possible, to have the exhaust system in the laboratory very similar to the system installed on the vehicle. This ensures almost same exhaust system pressure at the test bed condition. Also otherwise, the pronounced effect of standing wave in the exhaust system on engine performance is neglected. There may be some difference in the cooling of engine between it in the installed condition in the vehicle and that on the test bed. This can result in a small difference in the power to drive the water pump or fan (which is usually small). The alternator should be arranged to charge a battery or be connected to a small load. The engine torque characteristics obtained must, of course, include the full throttle on full load torque against engine speed curve. This is necessary for the calculation of vehicle accelerative performance and maximum speed. If it is intended to conduct steady-state calculations at vehicle speeds lower than maximum, such as the prediction of fuel consumption, it is necessary to obtain data throughout the engine load range. The parameter used to define an engine condition at other than the full load may be the throttle angle for a spark ignition engine or it may be the inlet manifold depression. Both are easy to measure.

Selection of a parameter to use as a measure of load is quite arbitrary. The fixed inlet manifold pressure is numerically a better indication of load because the throttle angle depends to a great extent on the carburettor. The normal throttle position is used and the engine is run over its speed range at each throttle setting. Then, by recording inlet manifold pressure with engine torque and fuel consumption data, it is possible to cross-plot the results to give lines of torque against engine speed at a number of constant inlet pressure values.

The usual parameter used to measure load on a compression ignition engine is the fuel pump rack position. However, when presenting graphs describing the performance of a compression ignition engine the measured data is usually reduced and cross plotted to give engine brake mean effective pressure (bmep) as the parameter describing load.

It is important to correct the measured data for ambient pressure and temperature, and so present results appertaining to a standard day. In this way, the results of one engine may be compared to those of another or the results of a particular engine corresponding to atmospheric conditions different from those of the test day. Fig. 31.2 represents the characteristics of a 1.6 liter spark ignition engine.

Fig. 32.2. Characteristic of a 1.6 LSI engine.