18.2.

Engine Mapping

Open-loop digital systems store ignition-timing and fuel mixture data in an ECU memory. The data stored in the individual cells of the computer’s memory can be represented graphically in the form of a characteristic map. Information for this map is found out by conducting a series

of tests on the engine and the program for these tests is called engine mapping. These tests determine the performance and investigate the effects of each variable that has some bearing on the output of the engine. When the effects are known, the settings that give the best performance can be determined and recorded.

A dynamometer is essential equipment for conducting these tests since it can be programmed to simulate road conditions. The engine is loaded by means of d3″namometer and the torque, power output, economy, and emissions are measured against speed and other factors that have certain effect on the engine output (Fig. 18.4).

Performance curves plotted manually or by computer represent graphically the behavior of the engine when it is subjected to changes in the following parameters.

• Speed

• Load (throttle opening)

• Ignition timing

• Air-fuel ratio

• Engine and ambient temperatures.

The performance curves derived from the tests are called engine maps. Some more important maps are discussed below.

18.2.1.

Torque/Consumption Loop

To plot this map the air-fuel ratio is varied and the fuel consumption and torque output are measured for each setting. Speed is kept constant during each test so that a series of tests is required to be conducted to cover the engine operating range.

Figure 18.5 shows a characteristic fish-hook shaped map, which is plotted for the engine operating under full-load. On the y-axis (vertical axis) the specific fuel consumption (SFC) is plotted and these values are obtained from the equation, SFC = fuel consumption (kg/h)/brake power (kW). The specific fuel consumption indicates the quantity of fuel necessary to produce one unit of power.

Fig. 18.4. Engine characteristics, full load test.

The map depicts that the engine develops low output torque but high fuel consumption i.e. high SFC when run on a weak mixture. As the mixture is enriched, the consumption falls to a point ‘E’ where maximum economy is attained. Enriching the mixture beyond this point causes an increase in torque but at the expense of fuel. Maximum torque and power occurs at point T’. It can be seen that the chemically correct ratio of 14.7:1 provides neither maximum torque nor maximum economy and to achieve these maximum results, the mixture must be slightly enriched and slightly weakened respectively.

18.2.2.

Exhaust Emission/Air-fuel Ratio

Fig. 18.5. Torque I consumption loop.

Before exhaust emission regulation were introduced, the air-fuel mixture used was based on the ratios required for either maximum power or maximum economy. Unfortunately the 12 – 15% enrichment from the chemically correct ratio to provide maximum power also produces a high emission of carbon monoxide (CO), hydrocarbons (HC) and nitrogen oxides (NOx) in the exhaust gases. (For further details chapter 17 may be referred).

Figure 18.6 represents the relationship between the release of undesirable gases in the exhaust and. the air-fuel ratios. This map illustrates that the operation of the engine on an enriched mixture should be avoided to minimize exhaust pollution. Comparing the results shown in Figs. 18.6 and 18.5, it can be seen that lean-burn engines designed to operate with minimum exhaust pollution suffer a considerable increase in consumption and decrease in power if the air-fuel ratio is weakened beyond the economy point ‘E’. Since the tolerance is very small, a close control of fuel metering is required if satisfactory output, combined with reasonable service life of engine is to be achieved.

Fig. 18.6. Exhaust emissions.

18.2.3.

Spark Timing and Engine Performance

The effects of varying the spark timing on engine performance have already been discussed in chapter 16. Maximum power is produced over the speed range when the spark is so timed that maximum gas pressure occurs at 12 degrees after TDC. Reducing the spark advance for a set engine speed reduces the power, increases the fuel consumption and, due to the slower burning of mixture overheats the engine. An over-advanced spark also gives poor performance and very likely causes combustion knock (detonation), which soon damages pistons and develops a high level of noise from ‘pinking’. In addition, the spark timing also alters the concentration of harmful constituents in the exhaust gas. Figure 18.7 represents a map obtained from running an engine at one set speed and load, and varying the ignition timing. This map provides the data for the best setting of the spark.

18.2.4.

Factors Affecting Spark Timing

Spark timing required to achieve a set power, depends on three main factors such as speed, load and air-fuel ratio.

(i) Speed: As the speed increases, the crank travels through a larger angle during the time taken for the gas to burn.

(ii) Load: As the load is increased, the opening of the throttle also increases to maintain a set speed. This increases the quantity of gas entering the cylinder, which causes the higher compression pressure, as a result the flame rate increases and the gas burns quicker.

(Hi) Air-fuel ratio: A weaker mixture takes longer time to burn than the chemically correct mixture.

The effects of these three factors can be determined by

Fig. 18.7. Effect of varying ignition timing.

using a series of maps so that the optimum timing can be established. The spark timing advance is increased when the engine speed is increased and air-fuel ratio is weakened. The spark timing advance is decreased when the engine load is increased and exhaust emission of HC and/or NOx is too high.

Fuel mixture requirements are related to engine load. When the engine is under light-load, or if the vehicle is cruising, a weaker mixture is supplied for better economy. During full-load condition high engine power is required; hence a less-weak mixture is supplied. Since the air-fuel ratio is mainly dictated by the load on the engine, the spark timing should only be responsive to load and speed, due to which most timing maps are based on these two variables.

18.2.5.

Three-dimensional Maps

After determining the optimum angle of advance with respect to speed based on the results of a series of engine tests at different loads, a large number of maps can be drawn. However all these maps can be reduced to one by using the three-dimensional form (Fig. 18.8). The x, y and z three axes of the map represent speed, spark advance and load respectively. The number of tests used to construct the map detects the accuracy of spark timing obtained. A total of 60 timing settings are used in the simple map shown in the figure.

Fig. 18.8. Typical spark advance map (simplified).

To use the three dimensional map, consider determining the spark advance for a speed of 32 revolution per second (rps) and a half-load condition. The 32 point on the x-axis is located and the line from this point is followed until it intersects the half-load line. The height of the map at this intersection indicates the advance angle, which is 52 degrees in this example.

18.2.6.

Fuel Mixture Map

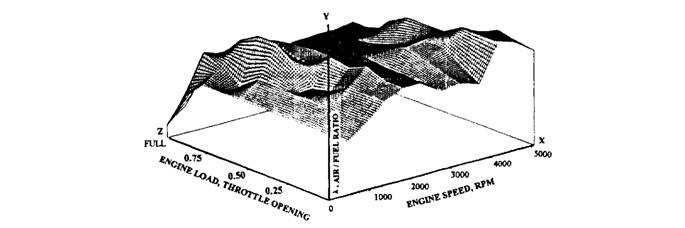

A three-dimensional map can also be drawn to find out fuel requirements of an engine. In this case the three variables are speed, air-fuel ratio and load which are plotted on x, y and z axes respectively. The plot indicates the air-fuel ratio required to suit the conditions of speed and load (Fig. 18.9).

Fig. 18.9. Fuel mixture map.

This map is often called a lambda map. The term lambda is the name of the Greek Letter ‘L’. The symbol X is used for the chemically correct mixture, or the stoichiometric ratio. At this ratio,

X = Supplied quantity of air/Theoretical air requirement = 1

When the X is less than 1 there is insufficient air for combustion, so the mixture is rich. When X is more than 1 there is excess air, so the mixture is weak.