ABSTRACT

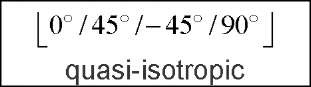

Impact responses and damage induced by a drop-weight instrument on GLARE 5 fiber-metal laminates with different layup configurations and geometries were studied. The damage characteristics were evaluated using both the nondestructive ultrasonic and mechanical sectioning techniques. Only the contour of entire damage area could be obtained using ultrasonic C-scan whereas more details of damage were provided through the mechanical cross-sectioning technique. It was found that failure mode changed with varying stacking sequence. GLARE 5 made of unidirectional fibers had the worst impact resistance; followed by cross-ply and angle-ply configurations, while the quasi-isotropic lay-up showed the best resistance to impact. Finally, influence of different geometries was considered. The results show that by introducing circular geometry, damage patterns and impact behaviors were changed. This was especially apparent for panels with the quasi-isotropic layup configuration.

INTRODUCTION

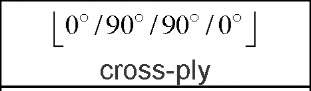

GLARE 5 is a fiber-metal laminate (FML) made of alternating layers of 2024-T3 aluminum alloy sheets and S2-glass/epoxy laminates. FMLs combine the beneficial properties of metals and fiber-reinforced polymers, providing superior mechanical properties in comparison with conventional polymer matrix composites or aluminum alloys [1-3]. Liu et al. [4] investigated low velocity impact damage on ARALL 3 and various GLARE grades, i.e., GLARE 1, 2 and 3. They found that GLARE 1 with glass-epoxy prepregs possessed higher impact tolerance than ARALL 3 with aramid-epoxy prepregs. They also concluded that GLARE 3 with [0°/90°] cross-ply glass-epoxy prepregs offered better impact resistance than GLARE 2, which is made of [0°2] unidirectional glass-epoxy prepregs. Hitchen et al. [5] considered the effect of stacking sequence on impact damage in a carbon fiber-epoxy composite. They concluded that the stacking sequence influenced both the pre- and post-compression strengths and affected the impact damage in 16-ply carbon fiber toughened epoxy laminates. They also reported that the total delamination area was a function of the stacking sequence. Choi et al. [6] concluded that ply orientation and stacking sequence could significantly affect impact damage. They also found that impact damage was more sensitive to the change of stacking sequence than of thickness. The influence of lay-up configuration on graphite-epoxy composite material was studied by Guynn et al. [7]. They concluded that the difference in compression failure strain due to stacking sequence were small. Cantwell [8] studied geometrical effects in the low velocity impact response of GFRP. He drew a conclusion that tests on a range of circular and square plates had shown that the degree of damage within the structure was related to the force generated during the impact event.

In this study, the effect of stacking sequence and geometry were considered to evaluate the low velocity impact behavior of the GLARE 5 composite materials through drop weight tests. Optical imaging, ultrasonic C-scan and mechanical sectioning techniques were used to assess the impact damages.

EXPERIMENTAL PROCEDURES

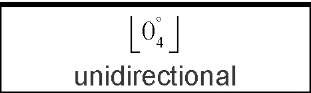

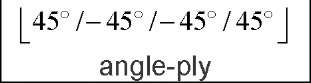

All GLARE panels considered in this study consist of 2024-T3 aluminum alloy with a thickness of 0.305mm (0.012") per layer and S2-glass/epoxy laminated layers, each with a thickness of 0.508 mm (0.020"). Each S2 -glass/epoxy layer has a layup orientation according to Table 1. Panels were cut into two different geometrical shapes: square and circular, with dimensions of 101.6 mm x 101.6 mm (4" x 4") for the square specimens and 101.6 mm (4") in diameter for the circular specimens. The typical mechanical properties of constituents are described in Table 2 [9-11]. In Table 1, the term MVF represents metal volume fraction and is defined as the ratio of the sum of the thicknesses of all aluminum layers over the total thickness of the fiber-metal laminate [12]:

Table 1. GLARE 5 panels tested in this study with different stacking sequences.

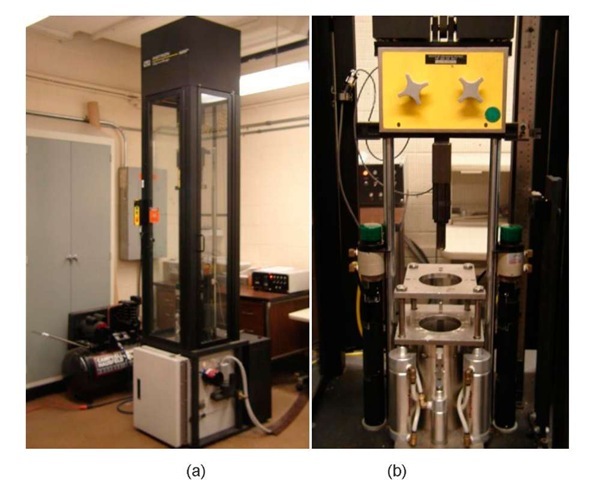

All impact tests were conducted using an Instron Dynatup 8250 pneumatic-assisted, instrumented drop-weight impact tester as shown in Fig. 1. The specimens were clamped circumferentially along a diameter of 76.2 mm (3") in the specimen fixture and impacted by a hemispherical steel impactor of diameter 16 mm with a mass of 6.14 kg. A pair of pneumatic breaks was also used to ensure no multiple strikes during impact test. The contact force history of impact was measured using a load cell located right above the impactor nose, and the impactor velocity was recorded by a pair of photoelectric-diodes attached to the base of the test machine. The time histories of the impactor position and the absorbed energy were obtained numerically by applying Newton’s law and energy balance principle.

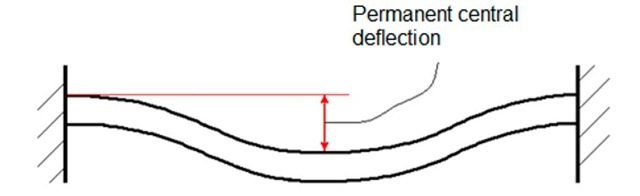

After each test, the specimen was carefully removed from the fixture for post-impact damage assessments. Figure 2 illustrates how the post-impact permanent central deflection was measured. Both nondestructive and destructive evaluation techniques were used to assess the impact damage inside the impacted panels. The impacted specimens were first scanned through an UltraPAC immersion ultrasound system for nondestructive damage evaluation, then carefully sectioned into two halves by a diamond saw through the impact center. Finally cross-sectional optical pictures were taken in order to reveal the more detailed damage inside the specimens. In this study a pair of 5 MHz ultrasonic transducers (one focused and another flat) in through-transmission mode was adopted to access the damage in the impacted specimens.

Table 2. Typical values of mechanical properties.

|

Mechanical property |

Aluminum 2024-T3 |

UD S2 Glass/FM 94 Epoxy Prepreg |

|

Tensile ultimate strength (MPa) |

L 455 T 448 |

1900 57 |

|

Tensile yield strength (MPa) |

L 359 T 324 |

- |

|

Tensile modulus (Gpa) |

L 72 |

54 9.4 |

|

Ultimate strain (%) |

L 19 |

3.5 0.6 |

|

Compressive yield strength (MPa) |

L 303 T 345 |

- |

|

Compressive modulus (GPa) |

L 74 |

54.4 11 |

|

Density (g/cm3) |

2.79 |

2.00 |

|

The symbols, L and T, stand for longitudinal (the rolling direction for the metal) and transverse directions, respectively. |

||

Figure 1. (a) Drop Weight impact tester, (b) The specimen fixture.

Figure 2. Measurement of the permanent central deflection.

RESULTS AND DISCUSSION

• SQUARE SPECIMENS

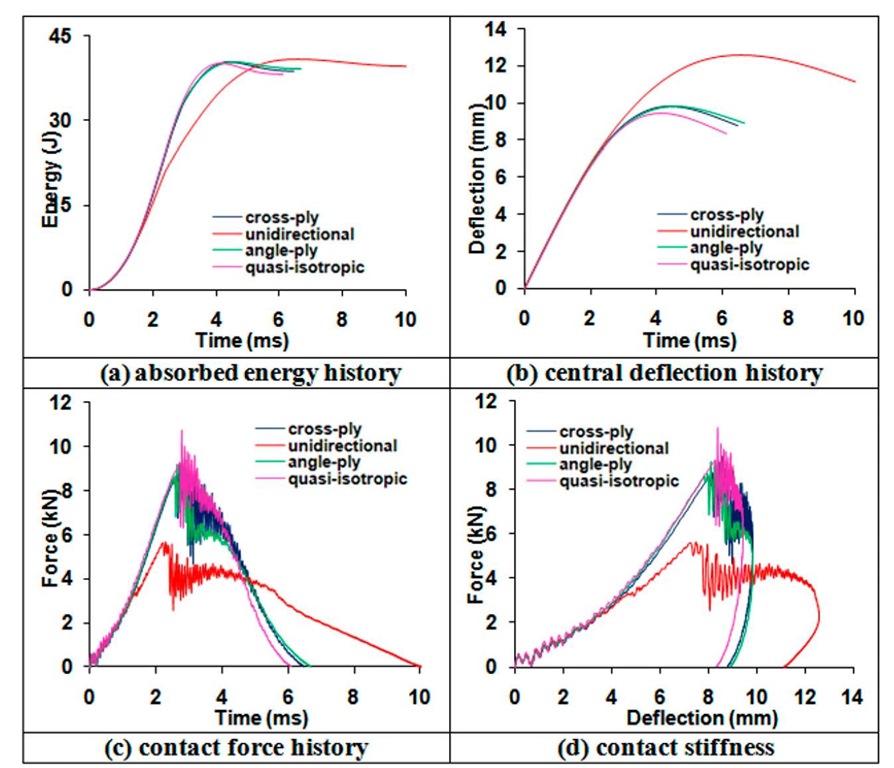

Stacking sequence effect was studied on GLARE 5 (3/2) specimens with different stacking sequences, namely: unidirectional, angle-ply, cross-ply and quasi-isotropic. Several drop-weight tests were conducted on GLARE 5 (3/2) with the cross-ply layup orientation, as a benchmark, in order to choose a proper impact energy to study and compare the impact responses and damage patterns of the GLARE 5 (3/2) of various stacking sequences. Based on the test results, 40J impact energy was chosen. Figure 3 shows the histories of absorbed energy, central displacement, contact force and contact stiffness for the square GLARE 5 (3/2) specimens with cross-ply[0°/90°]s, unidirectional^], angle-ply [+45°/-45°]s and quasi-isotropic[00/+45°/-450/90°] layup sequences. The corresponding C-scan results, back-side (non-impacted) views, as well as the cross-sectional views are shown in Figs. 4 and 5.

Figure 3. Impact responses of the cross-ply, unidirectional, angle-ply and quasi-isotropic GLARE 5 (3/2) square specimens under 40J impact energy.

The absorbed energy history revealed that under the same impact condition, unidirectional panel released less energy whereas quasi-isotropic panel released the most among the other type of panels. The peak value of central displacement history was the highest for the unidirectional panels while the lowest was for the quasi-isotropic panels. For the GLARE 5 (3/2) cross-ply and angle-ply, this peak was the same. Hence, the quasi-isotropic panels offered more resistance to the indentation than any other type of panels. The unidirectional panels were the worst panel to sustain the impact. By comparing the contact force histories, the unidirectional panels had the lowest peak contact force and the longest contact time duration. The quasi-isotropic panels offered the highest peak contact force among the other panel types. It is worth noting that although the patterns of contact force history for the GLARE 5 (3/2) panels with various layup configurations were similar, the damage patterns were different. From Fig. 3(d), it could be observed that contact stiffness curves started to deviate at time 1.16 ms, corresponding to 4.1 mm of the central deflection.

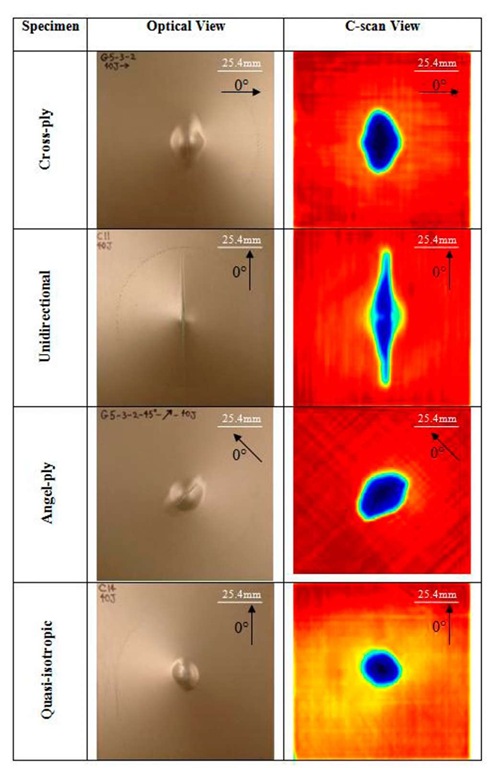

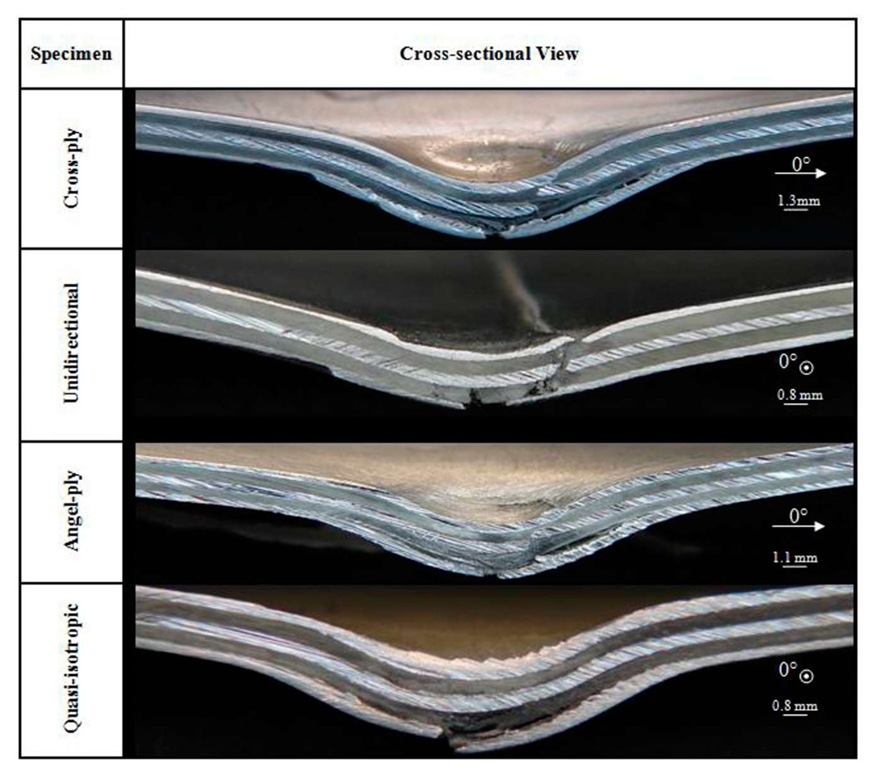

Mechanical-sectioning technique revealed that the major types of damage for the GLARE 5 (3/2) cross-ply panels were through-specimen crack, fiber breakage/splitting and delaminations (Figs. 4 and 5). The major delamination located between the non-impacted side aluminum layer and the adjacent glass-epoxy layer. Some small regional delaminations around the middle aluminum layer could also be found. A diamond-shaped damage zone was induced with major diagonal along 90°. For the unidirectional panels, long visible through-the-thickness cracks occurred, in which the cracks extended near the clamped edge. There was not much delamination besides fracture of aluminum layers and the splitting of the glass-epoxy layers for the unidirectional panels. Since there was no bending stiffness mismatch in a unidirectional prepreg layer, no delamination was expected in the interface of the unidirectional prepreg layer. The fracture of aluminum in the non-impacted side resulted from bending while the stress concentration induced the crack in the impacted face. The damage zone observed from C-scan looked like a lip-shaped with the major axis aligned along the fiber direction. The damage pattern for the angle-ply panels was very close to the cross-ply panels except the damage contour for the angle-ply panels was smaller than the cross-ply panels (Fig. 4). Furthermore, from the C-scan results, the major diagonal, i.e. perpendicular to the fiber direction, was noticeably shorter for the angle-ply panels compared to the cross-ply panels. This means that the GLARE 5 (3/2) panels with the angle-ply stacking sequence resisted more to impact compared to the cross-ply lay-up with the same panel configuration. The reason for this is believed to be due to the fact that the angle-ply panels offered more shear stiffness than the cross-ply panels. For the quasi-isotropic panels, major damage were crack in the non-impacted side aluminum, damage in the bottom [0°/+45°/-45°/90°] prepreg layer as well as significant delamination between the -45° and 90° layers. An approximately circular-shaped damage zone could be detected through ultrasonic C-scan for the quasi-isotropic panels. It is worth noting that under 40J impact energy, a visible crack appeared in all specimens on the non-impacted side. The crack was straight for the cross-ply, unidirectional and angle-ply GLARE 5 (3/2) specimens whereas it was not straight for the quasi-isotropic specimens.

Based on the discussion above, GLARE 5 (3/2) made of the unidirectional layup offered the worst impact resistance, followed by cross-ply and angle-ply layups, while quasi isotropic layup showed the best resistance to the impact. The reason for this is that the specimen stiffness decreased as layup configuration changed from quasi-isotropic layup to unidirectional. In other words, propagation of damage was alleviated and delayed as the bending stiffness mismatch decreased.

Figure 4. Back-side (non-impacted) view and corresponding C-scan view of the GLARE cross-ply, unidirectional, angle-ply and quasi-isotropic GLARE 5 (3/2) square specimens under 40J impact energy.

Figure 5. Cross-sectional view of the cross-ply, unidirectional, angle-ply and quasi-isotropic GLARE 5 (3/2) square specimens under 40J impact energy. The symbol ® means that the fiber direction is perpendicular to the cross-sectional view picture.