ABSTRACT

The problem of crack growth in a three-point bend specimen made of polymeric foams is investigated. Polymeric foams are anisotropic materials and cracks, generally, propagate under mixed-mode loading. The axes of material anisotropy are inclined with respect to the crack plane. Due to the anisotropy of the material crack kinking occurs even though the applied load is symmetrical with respect to the crack plane. The study will take place within the frame of linear elastic fracture mechanics of anisotropic media. The strain energy density criterion will be used for the determination of the critical load of crack initiation and crack growth path under mixed-mode loading. The opening-mode and sliding-mode stress intensity factors are determined by a finite element program. A special circular core element surrounding the crack tip with 19 nodes is used. The core element is joined to the conventional 12-node quadrilateral element by requiring that the displacement at the nodes on the circumference of the core element match the corresponding singular solution. Results are obtained for the critical load of crack initiation and crack growth trajectories as a function of the orientation of the axes of material symmetry and the anisotropy of the material.

Introduction

Cellular materials have extensively been used in sandwich construction due to their excellent properties, such as high specific modulus and strength, low weight, good thermal insulation and low cost. The mechanical behavior of cellular materials has been studied in [1-4]. It was found that the compressive stress-strain behavior of PVC cellular foams consists of an initial relatively small and stiff elastic regime, an extended stress plateau regime and a final regime in which densification of the material takes place. In the stress plateau regime the cells of the foam collapse, while the average stress remains almost constant during the instability spread through the material. Axial compression produces little lateral spreading resulting to almost zero Poisson’s ratio. When all of the cells co l-lapse the material is densified and its stiffness increases. As a consequence of such behavior foams change their volume during plastic compression. This is contrary to dense solids which are incompressible during plastic deformation. On the contrary, the uniaxial stress-strain behavior in tension is nonlinear elastic without any identifiable yield region.

The objective of this work is to study the problem of crack growth in a three-point bend specimens in a cross-liked polymeric foam under the commercial name Divinycell H250 with a density of 250 Kg/m3. The problem is analyzed by finite elements. The results of stress analysis are coupled with the strain energy density theory to obtain crack growth trajectories for various values of the angle of orientation of the axes of anisotropy of the material with respect to the loading direction.

Mechanical Characterization of Foam Materials

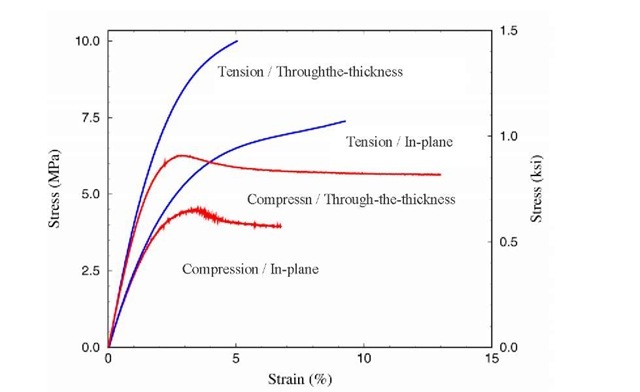

The study will include many types of fully cross-linked PVC closed-cell foams under the commercial name Diviny-cell H80, H100, H160, H250 with densities of 80, 100, 160 and 250 kg/m3, respectively, and balsa wood. Figure 1 shows the stress-strain curves of Divinycell H250 in tension and compression. Note that the uniaxial stress-strain behavior in tension is nonlinear elastic without any identifiable yield region. In uniaxial compression the material is nearly elastic-perfectly plastic in the initial stage of yielding. Mechanical properties of materials studied are shown in Table 1. All Divinycell H80, H100, H160 and H250 materials exhibit axisymmetric anisotropy with much higher stiffness and strength in the cell (3-direction) than the in-plane direction. The ratio of the stiffness in the cell (e-direction) to the in-plane direction is of the order of 1.5. The anisotropy of balsa wood is more pronounced with the above ratio equal to 42. All materials display different behavior in tension and compression with tensile strengths much higher than corresponding compressive strengths.

Fig. 1: Stress-strain curves of Divinycell H250 PVC foam, in tension and compression.

Strain Energy Density Criterion

The basic quantity in the strain energy density theory for crack problems is the strain energy density function dW/dV, which can be put in the form [5-7]:

where S is the strain energy density factor and r is the distance measured from the crack tip.

For plane elastic problems under conditions of plane stress the strain energy density function is given by

are the stress and ex, ey, Yxy are the strain components.

where

are the stress and ex, ey, Yxy are the strain components.

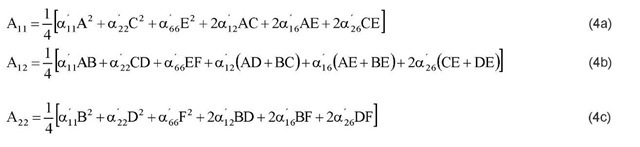

The strain energy density factor S is given by [5-7]:

where

with

and

In the above equations ay are the compliance coefficients of the anisotropic material relating stress and strain, K1 and K2 are the stress intensity factors which dictate the stress field in the neighborhood of the crack tip, z1 = x1 + iy-i, z2 = x1 – iy1 are complex numbers, and the other coefficients are related to the anisotropic behavior of the material [4-6].

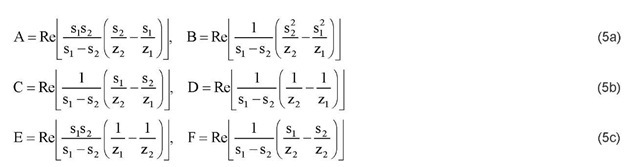

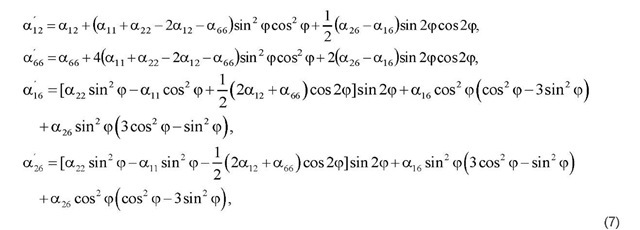

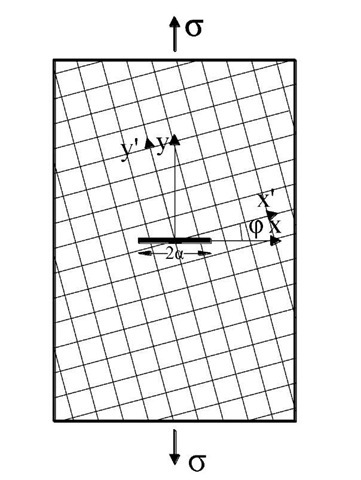

Consider a plate with a through-the-thickness crack of length 2a that is subjected to a uniaxial stress a perpendicular to the crack plane. The axis x’ of orthotropy of the material makes an angle ^ with the crack axis, x (Fig. 1). The compliance coefficients ajj’ referred to the system x’y’ (Fig. 1) are related to the coefficients ay refereed to the system xy by the following equations [5-7]

Fig.2 A cracked plate with a crack perpendicular to the applied load at an angle with the direction of the axis of material orthotropy of the material

According to the strain energy density theory unstable crack growth takes place in the radial direction along which S becomes minimum. This condition is mathematically put in the form:

This equation is used for the determination of the critical angle 0c of initial crack growth.

Unstable crack growth occurs when Smin(6c) takes its critical value Sc which is an intrinsic material parameter, that is,

Equations (8) and (9) will be used for the determination of the critical quantities at crack instability for the case of Fig. 1.

Results

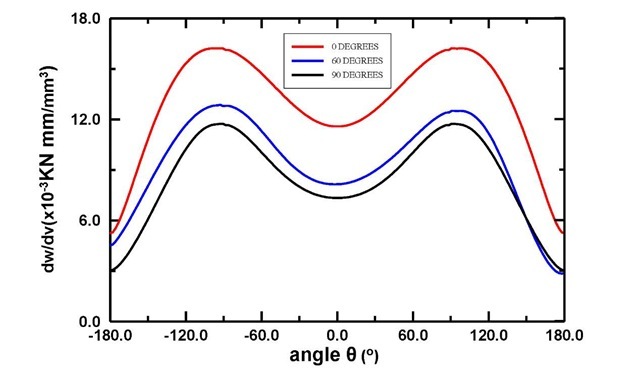

Results were obtained for a three-point bend specimen with a symmetrical crack (Fig. 3). The axis of material symmetry made an angle 9 with respect to the crack axis (Fig. 2). The stress analysis of the plate was performed by the ABACUS computer program. Figs 4 and 5 present the finite element idealization of the specimen in the vicinity of the crack tip. Fig. 6 presents the variation of strain energy density function dW/dV along the circumference of a circle centered at the crack tip for 9 = 0, 300 and 600. The values of 8 at which dW/dV presents local minima are the critical values of the angle of initial crack growth.

Fig. 3 A three-point bend specimen with a symmetrical crack

Fig. 5 Detailed mesh

Fig. 6 Variation of strain energy density function dW/dV versus polar angle 8 around the circumference of a circle surrounding the crack tip at a distance of 0.012 mm from the crack tip for 9 =0, 300 and 600. Crack grows in the direction of local minimum of strain energy density function

Conclusions

The crack growth in polymeric foams which present mechanical anisotropic behavior was studied. The case of a three-point bend specimen with the axes of material anisotropy at an angle with respect to the crack plane is analyzed. From the results of stress analysis in conjunction with the strain energy density theory the mixed-mode crack growth behavior of the plate was obtained. Results for the angle of initial crack growth for various orientations of the axes of anisotropy of the material with respect to the loading direction were reported.