Abstract

Solar water heating is one of the most successful applications of solar thermal technologies. It provides environmentally clean energy and has enormous potential within domestic and industrial sectors. Solar water heaters are categorized into three main types: thermosyphon, built-in-storage, and forced circulation. This entry provides the fundamentals of solar water heating technology and a description of parameters that determine the performance of a solar water heating system. Economics of solar water heating and the market trends around the world have also been discussed. Results from a specific life cycle assessment (LCA) undertaken on built-in-storage solar water heater are also presented.

INTRODUCTION

Energy is imperative for human life. The accomplishments of civilization have largely been achieved through the increasingly efficient and extensive harnessing of various forms of energy to extend human capabilities and ingenuity. One of the biggest challenges to mankind in the 21st century is to develop methods of generating and using energy that could meet the rapidly growing energy demands while protecting the global ecosystem. Renewable energy resources such as solar energy, wind power, biomass, and geothermal energy are abundant, inexhaustible, and environmentally friendly. Solar energy is one of the most promising types of renewable energy that has the potential to meet the energy demand of the entire planet. Solar water heating, one of the oldest and the most successful applications of solar thermal technologies, utilizes solar energy to heat water without producing any harmful emissions into the environment.

Solar water heating, besides its domestic role, has a wide array of applications within the commercial sector (e.g., swimming pools, laundries, hotels, and restaurants) and the industrial sector (e.g., food and beverages, processing, and textile industries). Around the world, water heating accounts for as much as 15%-25% of the total energy consumed in the domestic sector. In the United States and United Kingdom, for example, water heating, respectively, consumes 18 and 23% of the domestic energy.[1'2] In the industrial sector, water heating may account for a significantly higher share of energy usage. In the textile sector, for example, water heating can account for as much as 65% of the total energy used during processes such as dyeing, finishing, drying, and curing.[3] Solar water heating systems can also be used for large industrial loads and for providing energy to district heating networks.

A solar water heating system essentially consists of a collector and a water storage tank. The collector absorbs solar radiation and transfers it to the water stored in the tank. Residential, commercial, and a considerable number of industrial applications often require hot water that is at a temperature of less than 60°C. The required hot water temperature, however, could vary depending upon the type of activity especially within the textile sector where it often needs to be near the boiling level. Modern solar water heaters can accomplish these temperatures. However, taking into account various factors such as unpredictable weather conditions (rain or overcast sky) and a solar heating system’s size limitation in case of high demand, solar water heaters require a conventional heating system as a back up. A typical domestic solar water heating system can provide up to two-thirds of the total hot water requirements cutting down on fossil-fuel energy costs and also reducing the associated environmental impacts. There is a significant environmental penalty associated with the combustion of hydrocarbon gas with 14,000 g of C02 and 65 g of NOx emitted per GJ of energy released. This can be reduced by using solar water heater.

This entry provides fundamentals of technology for solar water heating and a description of parameters that determine the performance of a solar water heating system. Economics of solar water heating and the market trends around the world are also discussed. Results of a life cycle assessment (LCA) study of a built-in-storage solar water heater are also presented.

SOLAR WATER HEATER DESIGNS

Solar water heaters can be categorized into three main types: thermosyphon, built-in-storage, and forced-circulation. Thermosyphon and built-in-storage types are also regarded as passive systems as they rely on the natural circulation of water. The forced-circulation type of heater, on the other hand, is regarded as an active system as it incorporates an external element such as an electric pump to circulate the water. Solar water heaters transfer heat to the water in two ways: a direct system in which the collector itself transfers the heat to water, and an indirect system in which a heat-transfer fluid, circulating in the collector in a closed loop, transfers the heat to water through a heat exchanger.

Thermosyphon Solar Water Heater

The thermosyphon system operates on the principle that cold water has a higher density than warm water, and so being heavier, will sink down. Therefore, the collector is always mounted below the water storage tank, so that cold water from the tank reaches the collector via a descending water pipe (see Fig. 1). The collector absorbs solar radiation and transforms it into thermal energy and induces that energy to the water inside. As the temperature of the water in the collector rises, its density decreases. A circulation is thus established which enables the tank water to be progressively heated. The temperature of water at any point in the circulation determines its corresponding density. If this density variation is plotted against the height contour of the circuit, the magnitude of the driving force for water circulation is obtained. Owing to the low flow rates encountered within such systems, the driving force is balanced against the friction offered by the fluid circuit. The flow rates can thus be estimated. A thermosyphon system’s storage tank must be positioned well above the collector, since otherwise the cycle can run backwards during the night, cooling down all the heated water. Furthermore, the cycle does not work properly at very small height differences. To avoid flow reversals, it is recommended that the bottom of the tank should be at least 300 mm above the top of the collector. This requirement makes the system inconvenient, particularly if the collectors are to be roof-mounted. Freezing may occur within the collectors during winter in a direct system. The solution is to employ a heat exchanger within the storage tank, with an anti-freeze solution added to water. This will, however, result in reduced system efficiencies and increased system cost.

Built-in-Storage Solar Water Heater

A “built-in-storage water heater,” also referred as an “Integral collector-storage system”, combines a flat-plate collector and storage tank in one unit. Built-in-storage water heaters can be further classified into plain and finned types.

Plain Built-in-Storage Water Heater

The construction of a built-in-storage water heater involves a rectangular box-like structure with the top face painted black and enclosed behind a single or double sheet of glass. The back surface and sides are properly insulated and the entire assembly is tilted at a suitable inclination. The built-in-storage water heater possesses several advantages over the other types. First, during the daytime, it operates at a higher efficiency owing to the fact that primarily no heat losses occur during water circulation. Second, in comparison with the thermosyphon and forced-circulation systems, the intimate contact of water with the absorber plate results in better heat transfer. Built-in-storage heaters are also compact in size and cheaper due to their simplicity of construction. Based on extensive measurements of a number of designs, Muneer has reported the effects of storage volume/collector area ratio, the number of glazings, and the mode of operation on the performance of built-in-storage heaters.[4] Kreider and Kreith have presented design details of a freeze-tolerant, built-in-storage solar water heater with embedded heat exchanger coil which uses a refrigerant to extract heat.[5] Also in this respect, Davidson and Hammonds have recently undertaken more work.[6'7]

Fig. 1 Schematic diagrams of thermosyphon and built-in-storage solar water heaters.

Finned Built-in-Storage Water Heater

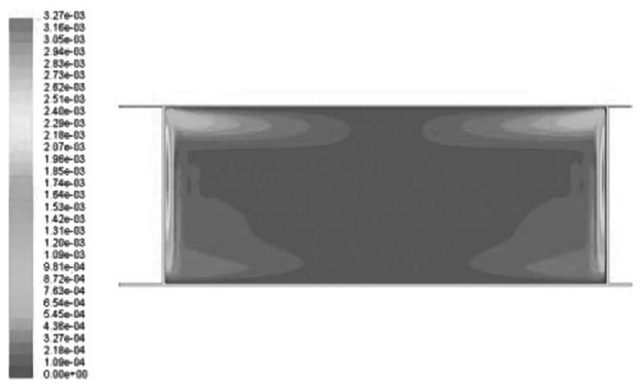

The finned type of built in storage solar water heater differs from the plain type only in terms of fins that are incorporated within the thermal collector plate. Fins in this design play a dual role: firstly, they act as a support for the top absorber plate, and thus avoid the bulging due to hydrostatic pressures exerted by the stored water within the heater. Secondly, the fin attempts to enhance the heat transfer process from the absorber plate to the innermost layers of water. Note that within the plain heater the fact that heat is being transferred from a heated plate at the top to a cooler body of water residing underneath is an inefficient convection process. On the other hand, the vertically placed fins have a better opportunity to transfer heat as shown in Fig. 2.[8]

Forced Circulation Solar Water Heater

In a forced-circulation solar water heater, water is actively pumped from the storage tank through the collectors and back into the tank. An electronic controller, a small pump, valves, and other components are needed for proper operation and maintenance. With a forced-circulation water heater, the collector and storage tank can be installed independently, and no height difference between tank and collector is necessary. Two temperature sensors monitor the temperatures in the solar collector and the storage tank. If the collector temperature is higher than the tank temperature by a certain amount, the control starts the pump, which moves the heat transfer fluid in the solar cycle; “switch-on” temperature differences are normally between 5 and 10°C. If the temperature difference decreases below a second threshold, the control switches off the pump again. Fig. 3 shows the schematic of a forced-circulation water heating system. In this design, the problem of placing the solar water tank above the collectors is removed. The water in tank A is the feed water for tank B which has a built-in auxiliary heater. In a more compact version of the forced-circulation system, the two tanks A and B are combined in a single unit. However, this reduces the overall efficiency of the system as the maximum exploitation of solar energy is inhibited.

TYPES OF THERMAL COLLECTORS

The solar thermal collector is at the heart of a solar water heater as it absorbs the solar radiations and then transfers the captured heat to water in the storage tank. Solar thermal collectors may broadly be classified as flat-plate or evacuated-tube collectors.

Flat-Plate Solar Collector

The main components of a flat-plate solar collector include a transparent front cover, a collector housing, and an absorber. The absorber is usually made of metal materials such as aluminum, copper, or steel. The collector housing can be made of plastic, metal or wood, and the glass front cover must be sealed so that heat does not escape, and dirt, insects, and humidity do not get into the collector itself. The collector housing is highly insulated at the back and sides, keeping heat losses low. However, there are still minor heat losses from the collector, mainly due to the temperature difference between the absorber and ambient air, and these are subdivided into convection and radiation losses. The former are caused by air movements, while the latter are the product of the exchange of heat by radiation between the absorber and the environment. A sheet of glass covers the collector as it faces the sun, and this helps to prevent most of the convection losses. Furthermore, it reduces heat radiation from the absorber into the environment in a similar way that a greenhouse does. However, the glass also reflects a small part of the sunlight, which does not then reach the absorber at all.

Fig. 2 Computational fluid dynamics (CFD) velocity distribution raster plot for a finned heater. The jets issuing from the left and right fins demonstrate their effectiveness in heating the otherwise quiescent body of water shown.

Fig. 3 Forced-circulation solar water heater with indirect cycle.

The heat-loss coefficient from any given collector determines its thermal efficiency. This value, in turn, is obtained from the heat loss from the collector top (f/T) and the overall loss coefficient (UjJ, i.e., the sum of heat loss from the top, sides, and bottom of the collector housing. For one commercially available single-glazed collector with a selectively coated absorber, f/T and jyL are 3.37 and 3.4 W/m2-K, respectively.19

Evacuated Tube Solar Collector

Evacuated tube solar collectors normally come in two types, coaxial-tube and heat-pipe designs. In the former design, a coaxial heat exchange pipe carrying a counter-flowing fluid is embedded within the absorber. The heat exchange pipe then feeds into a header. To enable maximum exploitation of solar energy, each vacuum tube is pivot mounted, enabling for the optimal orientation. The vacuum in the glass tubes ensures minimal convective heat loss while the selective coating helps suppress radiative losses. The top-loss and overall-loss coefficients for the collector presently under discussion are quoted as 1.37 and 1.375 W/m2-K.[9]

The design of the collector shown in Fig. 4 is based on the heat pipe principle. Basically a heat pipe is a closed container that employs an evaporating-condensing cycle.

Fig. 4 Evacuated tube solar collector design based on the heat pipe principle.

The transfer of heat from the absorber plate occurs via an efficient and fast heat conductor bearing a low heat capacity. The heat-pipe functions like a thermal diode. It accepts heat from an external source, uses this heat to evaporate the liquid (latent heat) and then releases latent heat by reverse transformation (condensation) to the heat sink. This process is repeated continuously by a return feed mechanism of the condensed fluid back to the heat zone. Typically, evacuated heat pipe solar collectors use a sealed steel pipe, containing alcohol. The pipe is then attached to a black copper fin that fills the tube (absorber plate). Protruding from the top of each tube is a metal tip attached to the sealed pipe (condenser). These tubes feed into a heat exchanger manifold. Under solar flux, the alcohol is heated and hot vapor rises to the top of the pipe. Water or glycol flows through the manifold and picks up the heat from the tubes. The heated liquid circulates through another heat exchanger and gives off its heat to water that is stored in a solar storage tank. The maximum operating temperature of a heat pipe is the critical temperature of this heat transfer medium. Since no evaporation/condensation above the critical temperature is possible, the thermodynamic cycle is interrupted when the temperature of the evaporator exceeds the critical temperature. The top-loss and overall-loss coefficients for the above collector are quoted as 1.34 and 1.346 W/m2-K.[9]

SYSTEM DESIGN

The rule of thumb for a solar water heating system storage design is to use an 80 l/m2 collector area for tropical locations, 60 l/m2 for the United States, Central Europe, and Canada, 40-45 l/m2 for the British Isles and Scandinavian countries.[1] Losses in the generation of domestic hot water maybe summarized as draw-off pipe losses, storage losses, losses in primary circulation pipes and those encountered during the heating up of the hot water generator. For a realistic plant simulation, these losses should be taken into account. In this section, basic mathematical models are presented which enable system simulation and design evaluation of solar water heating systems.

The Hottel-Whillier-Bliss Equation

An important relationship, which essentially represents the steady-state energy balance of any solar heat collector with an absorber area of Ac, is the Hottel-Whillier-Bliss equation (Eq. 2). This equation enables the calculation of useful energy gain (Qu) as a function of the fluid inlet temperature, Tj and ambient temperature Ta.

Eq. 1 enables the computation of f/T. It is customary to add 5%-10% to the value of f/T to obtain the total heat loss coefficient, jyL. Other terms used in Eq. 2 are explained below.

The Transmission-Absorption Product, (ra)

A solar radiation incident on any inclined collector is composed of direct (beam), sky-diffuse, and ground-reflected components. These transmitted components, passing through the collector glazing, may be estimated if the corresponding transmittances rb, rd, and rg are known. Each of these is a function of their respective irradiance incidence angles. Furthermore, part of the transmitted radiation is reflected back from the absorber plate to the cover system, which is, in turn, absorbed and reflected back to the collector plate. Therefore, as Duffie and Beckman have suggested, the transmittance-absor-bance product (to) should be thought of as a symbol representing a property rather than a straightforward product of the two fundamental properties, r and a. Duffie and Beckman[10] have presented a graphical solution for obtaining (to) from (ta)n.

Fin Efficiency (F’)

The fin efficiency factor, F1 represents the ratio of the actual energy gain to the energy gain that would result if the entire absorbing surface was maintained at the fluid temperature. Duffie and Beckman have presented the physical model for obtaining F’ which is shown to be a strong function of the absorber fin heat transfer efficiency, {/l, and other less significant parameters.[10] For most practical designs, F’ may be taken to have a value between 0.8 and 0.9.

Heat Removal Factor (FR)

The collector heat removal factor, FR, is the product of F’ and the flow factor, F”. FR is equivalent to the effectiveness of the solar collector’s heat exchange process. The flow factor is obtained from Eq. 3, which, in turn, enables the estimation of FR.

F” = (mCpIAcf/LF’)[1 - exp( - mCpIAcf/LF')] (3)

Measured Collector Performance

The basic method of obtaining collector performance is to operate the collector in a steady-state mode with coincident measurements of solar radiation, fluid flow rate, temperature gain, ambient temperature, and wind speed. In Eq. 2 the useful solar heat gain was written in terms of collector parameters. The efficiency of the collector is defined as

Eqs. 2 and 4 may be manipulated to express the efficiency as a linear function of the ratio of the temperature differential between the collector plate and the ambient air and the collector irradiation. Thus,

The European practice is to base the collector test results on Tp av which is the average of the inlet-outlet fluid temperature. Therefore, in Eq. 5 is replaced with T

* p,av

Eq. 6 may be simplified as

The X variable represents the term contained within the square brackets of Eq. 5.

Contrary to the dictum of Eq. 5, measured data show a slight non-linear variation of the data points, and as such, second-order models have been suggested for the above efficiency variation. For most practical purposes, though, a straight line fit should suffice.

System Simulation

Eqs. 1-5 enable a fairly representative, hourly simulation of solar water heating plants to be undertaken. A fullblown simulation is beyond the scope of this entry. A detailed simulation exercise would require collector thermal capacitance and tank temperature stratification effects to be taken into account. Hourly (and where applicable, temperature-dependent) estimation of FR, (to), and Ul may be undertaken with the hot water draw-off profile also incorporated within the simulation program.

ECONOMICS OF SOLAR WATER HEATING

Solar water heaters provide energy with economy. The economic payback period of a solar water heating system, however, is a function of various factors such as system efficiency, local weather conditions (i.e., the level of solar irradiance available), and the cost of fossil fuels. The initial cost of a solar water heater is higher than that of a gas water heater or an electric water heater that varies from region to region. A solar water heater can, however, be much more economical over the lifetime of the system than heating water with electricity, fuel oil, propane, or natural gas, depending upon the price of fuel sources. According to the findings of the Florida Solar Energy Center, the payback period for a well-designed and properly installed solar water heater could be between 4 and 8 years.[11] After the payback period, savings can be accrued over the life of the system, which ranges from 15 to 40 years, depending on the system and how well it is maintained. Muneer and Asif estimated the payback period for solar water heating incorporated within textile industries in Pakistan to be 6 years. More recent work has concluded that, with more efficient designs, the payback period can be reduced to just over 3 years.[8]

Table 1 Life cycle assessment of a built-in-storage solar water heater

| Entity | Quantity (kg) | Embodied energy (MJ) | Carbon released (kg) | Monetary costs (USD) |

| Stainless steel | 33 | 1155 | 20.13 | 108 |

| Glass | 11 | 340 | 6.70 | 5 |

| Glass wool | 2 | 40 | 1.75 | 2 |

| Rubber | 0.1 | 15 | 0.28 | 1 |

| Timber | 20 | 44 | 0.8 | 4 |

| Total | 1744 | 39.7 | 140 | |

| Savings/year | 3509 | 69.6 | 20 | |

| Payback period | 166 days | 156 days | 6.1 |

LIFE CYCLE ASSESSMENT (LCA) OF SOLAR WATER HEATERS—A CASE STUDY

Solar water heaters use solar energy as the fuel and hence are environmentally friendly, as they do not generate any toxic emissions during their operation. There are, however, environmental burdens associated with solar water heaters due to the materials used and the fabrication that is involved. In order to improve the thermal performance of a built-in-storage system, Muneer and Asif developed a finned device employing stainless steel, with a collector area of 1 m2 and capacity of 80 l. They conducted rigorous testing of the heater for a complete year to determine its performance under varying weather conditions in Pakistan. They also conducted LCAs to investigate its energy and environmental performance. Their findings are presented in Table 1.

Table 2 Installed solar thermal collector area for European countries (Muneer 2004)

| Country | 1 | 2 | 3 | 4 | 5 |

| Germany | 420 | 615 | 900 | 3.71 | 45.1 |

| Greece | 195 | 181 | 160 | 2.98 | 283.4 |

| Austria | 141 | 168 | 169 | 2.34 | 288.9 |

| France | 16 | 23 | 38 | 0.55 | 9.3 |

| Spain | 33 | 40 | 50 | 0.45 | 11.4 |

| Denmark | 22 | 27 | 40 | 0.32 | 60.6 |

| Italy | 16 | 18 | 17 | 0.31 | 5.5 |

| Switzerland | 30 | 26 | 27 | 0.26 | 36.1 |

| Portugal | 5 | 6 | 8 | 0.25 | 25 |

| Netherlands | 30 | 32 | 35 | 0.21 | 13.5 |

| Sweden | 9 | 18 | 13 | 0.21 | 23.9 |

| United | 9 | 10 | 11 | 0.21 | 3.5 |

| Kingdom | |||||

| Finland | 9 | 10 | 10 | 0.03 | 5.9 |

| Belgium | 2 | 2 | 3 | 0.02 | 2.4 |

| Ireland | 1 | 0.3 | 0.3 | 0.003 | 0.9 |

| Total | 914 | 1171 | 1488 | 11.9 |

The annual average daily incident solar irradiation on a 1 m2 collector area of the heater, under the test conditions for the above site was 4.8 kWh. The average daily energy yield of the heater was found to be 2.65 kWh, thus demonstrating an efficiency of 55%.[12] It was found that over a service life of 20 years, the heater would provide 19.4 MWh of energy. The heater consequently has a potential of saving 1393 kg of CO2 emission.

As part of this work, a life cycle cost assessment was also carried out. Compared to furnace oil systems, typically used within industrial settings, the solar water heater was found to have a payback period of 6 years.[8] Further work in this regard showed that the performance of the system could be significantly improved by employing aluminum collectors. Owing to the fact that aluminum is cheaper and has better thermal properties than stainless steel, the payback period of this type of system was found to be just over 3 years.

USER SURVEY AND MARKET GROWTH

The Energy Technology Support Unit (ETSU) undertook a survey of domestic users of solar water heaters. Users from all regions of the United Kingdom were surveyed on a number of issues ranging from the types of systems in use to economic viability and technical reliability of their systems. The majority of respondents (70%) registered their response as “very satisfied.” Any initial dissatisfaction was commonly reported as being due to installation problems. It was also observed that post-1986 improvement in manufacturing technology had resulted in increased user satisfaction. On an average, respondents had paid £2500 for their system. The overall conclusion was that the systems had shown a high reliability, with 85% of the systems sold since 1974 still in use.[1]

Since the early 1970s, the efficiency and reliability of solar water heating systems have increased significantly while the cost has dropped. Improvements to materials, a rating system for consumers, and more attractive designs, have all helped to make systems more successful. Particularly, over the last ten years there has been a significant increase in the use of domestic solar water heaters across the world. In 2003, solar water heaters received 21% share of the total investment, U.S. $22 billion, in the renewable energy sector worldwide.[13] In 2004, China’s solar water heating market grew by 30% as it installed well over 10 million m2 of new solar thermal collector area—equivalent to 7 GWth. In terms of installed capacity per capita, Israel, Greece, and Austria are the world leaders. The solar water heating market in France grew by over 30% per year during the last 3 years. In Spain, the solar water heating market has grown at a rate of 15% over the last 6 years while an annual growth target of 65% has been set until the year 2010. Similarly, other

European countries are also experiencing an upward trend as shown in Table 2.[14] Reported figures indicate a healthy growth in 2004 (compared with 2003) in several countries, even though the total market is still small. Belgium grew by 62%, Estonia by 67%, Hungary by 50%, Ireland by 67%, Malta by 41%, Portugal by 67%, and Slovenia by 64%. In the United States, solar water heating is becoming increasingly popular in domestic and swimming pool applications.1-15-1 From 1996 to 2004, for example, the Hawaiian Electric Company (HECO) has seen more than 25,000 solar water heater (SWH) systems installed within its customer base.[16]

CONCLUSIONS

Solar water heating is an energy efficient, cost effective and environmentally friendly renewable energy technology that has a huge potential in domestic and industrial applications. For most countries around the world, solar water heaters can provide up to two-thirds of the total hot water requirements while cutting down the energy cost and the associated environmental impacts. Due to its favorable characteristics, solar water heating is becoming increasingly popular across the world. In 2003 approximately 4.6 billion USD were invested in solar water heating, accounting for 21% of the total investment made within the renewable energy sector. China, a leading player in the solar water heating market, saw its solar water heating market grow by 30% in the year 2004. On the other hand, several European countries are experiencing an even healthier growth. On the basis of a case study presented in this entry, it may also be noted that the payback periods for built-in-storage heaters using stainless steel and aluminum may be expected to be, respectively, around 6 and 3 years.