2.6.

Firing Order of Cylinders

Cylinder firing order improves the distribution of the fresh charge in the manifold to the

cylinders and helps the release of the exhaust gases, while at the same time suppresses torsional

vibrations. These conditions are as follows.

(i) Successive cylinders firing allows a recovery of charge in the manifold and minimizes

interference between adjacent or nearby cylinders. Normally cylinders from opposite

end of the manifold are chosen or from alternate cylinder banks in *V engines to draw

alternately. This arrangement, however, becomes difficult as the number of cylinders

decreases.

(ii) Separating successive cylinders, which are exhausting, are even more important than

for induction. It is because if the exhaust periods overlap with the cylinders, exhaust-

gas back pressure may prevent escaping of products of combustion from the cylinders.

(Hi) Power impulses cause winding up of the crankshaft. In addition, if the natural

torsional oscillations of the shaft coincide with these disturbing impulse frequencies,

torsional vibrations may take place. Therefore, in general, it is desirable to have

successive power impulses to alternate ends of the crankshaft.

Fig. 2.15. Single-cylinder arrangement.

2.6.1.

Single-cylinder Arrangements

A single-cylinder engine has a power stroke every

720 degrees/1 i.e. 720 degrees of crankshaft rotation

for a four-stroke-cycle engine. The engine has simply

a single-throw crank-arm, and the rotating big-end

journal or crankpin is linked to the piston gudgeon

pin by means of a connecting-rod to have both a linear

and an oscillating motion (Fig. 2.15).

When piston is at TDC, it is either completing

compression and about to begin power stroke or it is

at the end of the exhaust stroke and beginning induction stroke. Assuming piston initially at

TDC at zero angle of crankshaft rotation, it is then at BDC at 180 degrees and 540 degrees, and

at TDC at 360 degrees and 720 degrees of crankshaft rotation.

2.6.2.

Twin-cylinder Arrangement

A. In-line Side-by-side

An in-line side-by-side twin-cylinder engine has a power

impulses every 720 degrees/2 i.e. 360 degrees of crankshaft

rotation. The crankshaft uses a single-throw crank-arm with

both pistons and connecting-rods attached to a common big-end

journal or crankpin (Fig. 2.16).

When piston 1 is at TDC, it is on the top of its compression

stroke and about to start its power stroke. Piston 2 is then at

its exhaust stroke at TDC and about to begin its induction

stroke. With 180 degrees of crankshaft rotation, both pistons

are at BDC and piston 1 is about to start its exhaust stroke and piston 2 its compression stroke.

A second 180 degrees of crankshaft rotation brings pistons 1 and 2 to TDC to begin their

induction and power strokes respectively. A third 180 degrees rotation of the crankshaft moves

the pistons to BDC, and piston 1 and 2 are about to start compression and exhaust strokes

respectively. A four-stroke cycle of720 degrees is completed when fourth rotation of 180 degrees

brings the pistons to the original starting position.

B. In-line 180 Degrees-out-of-phase

With this arrangement power impulses take place at un-

even intervals, i.e., at every 180 degrees and 540 degrees of

crankshaft displacement. The cylinders are positioned parallel

to each other, when piston 1 is at TDC, piston 2 is at BDC and

the crank-throws are 180 degrees out of phase with each other

(Fig. 2.17). If initially piston 1 is at the end of compression and

the beginning of its power stroke, then piston 2 is at the end of

power and at the beginning of its exhaust stroke.

First rotation of crankshaft through 180 degrees brings

piston 1 to BDC, about to begin its exhaust stroke after complet-

ing power stroke, while piston 2 is at TDC, at the end of exhaust

stroke and about start compression stroke. A second rotation of’

180 degrees moves pistons 1 and 2 to TDC and BDC respective-

Fig. 2.16. In-line side-by-side twin-

cylinder arrangement.

Fig. 2.17. In-line 180 degree^omt-

ofphase twin-cylinder arrangement.

Fig. 2.18. Horizontally opposed twin-cylinder

arrangement.

ly. The piston 1 is at the end of exhaust and at

the beginning of induction stroke, while 2 is

beginning its compression after completing its

induction stroke.

The third 180 degrees rotation of the

crankshaft brings piston 1 to BDC, ending induc-

tion and starting its compression stroke, while

piston 2 is at TDC and ready for next power

stroke after completing compression stroke. Fourth 180 degrees rotation of crankshaft moves

piston 1 to TDC and piston 2 to BDC bringing them to initial starting positon.

C. Horizontally Opposed

This arrangement provides power impulses at even intervals of every 360 degrees of

crankshaft rotation. The crank-throws are 180 degrees out of phase with each other. The

connecting-rods and pistons are positioned on opposite sides of the crankshaft, horizontally

opposed (Fig. 2.18) with the cylinder axes offset to each other. Therefore, pistons approach TDC

and BDC positions together although, they move in opposite directions at all times. Assuming

pistons are at TDC, piston 1 at the end of compression and the beginning of power stroke, and

then piston 2 finishes exhaust and about to start its induction stroke..

First, second and third 180 degrees rotation of crankshaft bring the pistons to BDC, TDC

and BDC positions respectively performing their respective strokes as indicated in the figure.

Fourth 180 degrees rotation completes the cycle of events of four-stroke cycle and brings the

pistons to their initial starting positions. These engines are used in small motorcars.

D. 90 Degrees *V

In this arrangement, two cylinders are positioned at 90 degrees to each other with both big

ends attached to a single crankpin (Fig. 2.19). With this configuration power impulses have

uneven intervals, which take place every 270 degrees and 450 degrees of crankshaft movement.

Cylinder banks are designed to form V either at left-hand or right-hand when looking from the

front of the engine. Side-by-side connecting roads are used, and two banks of cylinders are offset

relative to each other.

Assuming piston 1 first at the end of compres-

sion stroke in readiness for firing and piston 2 is

then at mid-stroke approaching TDC on either its

exhaust or its compression stroke. Let piston 2 is

at mid-stroke on its exhaust stroke. Rotation of

the crank through 450 degrees completes its ex-

haust, induction, and compression strokes in

readiness for firing. At this point piston 1 is at

mid-stroke on induction stroke, so rotation of the

crank through a further 270 degrees completes

both its » i action and compression strokes. The

total cranK-angle interval for these two firing

events adds up to 450 + 270 i.e. 720 degrees.

The V-twin cylinder engines can have only a moderate degree of dynamic balance, and their

uneven filling intervals and insufficient cyclic-torque smoothness make them unsuitable for the

Fig. 2.19. V-twin cylinder arrangement.

car. This case has been discussed in order to explain the basic arrangement of V-bank cylinders

with connecting-rods sharing a common crankpin. This is important engine layout.

2.SJ3.

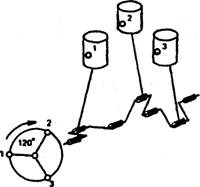

In-line Three-cylinder Arrangement

A three-cylinder engine has a power impulse every 720 degrees/3 i.e. 240 degrees of

crankshaft rotation for the four-stroke cycle operation. The crank-throws and crankpins are

spaced at intervals of 120 degrees and four main journals and bearings are provided (Fig. 2.20)

to support the crankshaft.

With piston 1 at the top of the compression stroke and start of its power stroke, pistons 2

and 3 are at 60 degrees crank-angle from BDC on their induction and exhaust strokes

respectively. A120 degrees rotation of crankshaft places piston 3 at TDC at the end of its exhaust

stroke and beginning of its induction stroke, and pistons 1 and 2 at 60 degrees from BDC on

their power and compression strokes respectively.

A second 120 degrees rotation of crankshaft moves piston 2 to TDC, completing compression

stroke in readiness for its power stroke. Pistons 1 and 3 are at 60 degrees from BDC on their

respective exhaust and induction strokes. Third 120 degrees movement brings piston 1 to TDC

so that it just ends exhaust stroke and about to begin its induction stroke. Pistons 2 and 3 now

are at 60 degrees from BDC on their respective

power and compression strokes. Finally a fourth

120 degrees of crankshaft rotation places piston

3 at TDC on its compression stroke and ready to

start power stroke. This sequence of events

results in a firing order of 1, 2, 3.

These engines are dynamically balanced.

The extra cylinder smoothes out the cyclic torque

sufficiently so that the engine stands as a com-

petitor to the popular four-cylinder configura-

tion. This configuration provides savings in

weight and length, and has reduced reciprocating

and rotational drag, which improves fuel con-

sumption.

2.6.4.

Four-cylinder Arrangement

A. In-line

A four-cylinder in-line engine has a power im-

pulse every 720 degrees/4 i.e. 180 degrees of

crankshaft movement. The crankshafts have crank-

throws situated at intervals of 180 degrees to each

other in the order in which the power impulses are

intended. With this crankshaft arrangement (Fig.

2.21), all four crank-throws lie in one plane,

crankpins 1 and 4 being in phase but at 180 degrees

to crankpins 2 and 3.

Assuming crankpin 1 is at the top of a compres-

sion stroke, crankpin 4 must be at the top of an

exhaust stroke and crankshaft rotation makes then

Fig. 2.20. In-line three-cylinder arrangement.

Fig. 2.21. In-line four-cylinder arrangement.

to descend on a power stroke and on an induction stroke respectively. Rotation of the crankshaft

through 180 degrees places big-ends 1 and 4 at the bottom of their strokes, while big-ends 2 and

Satthetopoftheir storkes after either a compression or an exhaust stroke. Further it is assumed

that piston 3 be the next to descend on power stroke, while piston 2 descends on an induction

stroke. The order of firing is then 1,3.

A second 180 degrees movement of crankshaft positions crankpins and pistons 1 and 4 at

the top of their exhaust and power strokes respectively, so that at this point the order of firing

is 1, 3, 4. A third crankshaft rotation of 180 degrees again places pistons 2 and 3 at the top of

their stroke. As piston 3 previously descended on a power stroke, piston 2 is now on its power

stroke, so that the complete firing order is 1, 3, 4, 2. A final 180 degrees rotation completes 720

degrees displacement of crankshaft in a four-stroke engine.

If cylinder 2 is selected instead of cylinder 3 to fire after cylinder 1, then firing order would

be 1,2,4,3. Both these firing orders have equal merits and limitations with respect to crankshaft

torsional wind-up and the uneven breathing intervals between adjacent cylinders. In-line

four-cylinder engines in the capacitors from 0.75 to 2.0 liters are most popular.

B. Horizontally Opposed Flat

This arrangement requires a single-plane crankshaft with crankpins spaced at 180 degrees

intervals. Therefore the crank-throws are paired so that crankpins 1 ad 4 are diametrically

opposite to crankpins 2 and 3 (Fig. 2.22). Let pistons 1 and 2 are at TDC, and pistons 3 and 4

at BDC for the consideration of firing order. Let piston 1 is at the end of its compression stroke

and just to start power stroke, then piston 2 is completing exhaust, while pistons 3 and 4 are at

power and induction strokes respectively.

Rotation of the crankshaft through 180 degrees places pistons 3 and 4 at TDC at the end of

their respective exhaust and compression strokes and

piston 4 is about to start power stroke. Pistons 1 and

2 are at BDC completing their respective power and

induction strokes. The order of firing is 1, 4. A second

180 degrees of rotation brings piston 1 and 2 to TDC,

at the end of their respective exhaust and compres-

sion strokes, while piston 3 and 4 are at BDC com-

pleting their respective induction and power strokes.

The order of firing is 1, 4, 2.

A third 180 degrees rotation brings piston 3 and

4 to TDC at the end of their respective compression

and exhaust strokes, while piston 1 and 2 are at BDC

completing their respective induction and power

stroke. The complete order of firing is 1,4,2,3. A final

180 degrees rotation completes 720 degrees of

crankshaft displacement.

The flat four-cylinder engine has slightly better dynamic balance than the in-line four-

cylinder engine, but the smoothness of torque is equal in both the cases. The flat shape makes

it suitable for rear mounted engines but opposed cylinder allow very little room for cylinder head

servicing.

Fig. 2.22. Horizontally opposed flat four-

cylinder arrangement.

C.60 Degrees ‘V

In this arrangement the cylinders fire at equally spaced intervals of 180 degrees and are

placed with numbers 1 and 2 in the left-hand bank and numbers 3 and 4 in the right-hand bank.

The crankpins are unequally spaced at alternate intervals of 60 degrees and 120 degrees (Fig.

2.23), and they lie in two planes when viewed from the front. Main journals and bearings are

provided at each end, with a third journal between crankpins 2 and 3. With such an arrangement

pairs of pistons are at the top of their strokes but in different cylinder banks.

When pistons 1 and 4 are at TDC, either of these may be chosen to be at the end of its

compression stroke and about to fire. The other piston

would then be at the end of exhaust and just beginning its

induction stroke. Let pistons 1 and 4 are at the end of its

compression and exhaust strokes respectively. Rotation of

crankshaft through 180 degrees places pistons 2 and 3 at

the top of their respective exhaust and compression

strokes, causing the order of firing as 1, 3 at this point.

A second 180 degrees rotation brings pistons 1 and 4

to TDC position again, with piston 1 completed its exhaust

stroke and about to start its induction stroke, while piston

4 is at the end of compression and about to begin power

stroke. The order of firing up to this point is 1,3,4. A third

180 degrees rotation positions pistons 2 and 3 at TDC,

with piston 2 at the end of compression and about to begin

its power stroke. The complete order of firing now is 1, 3,

4, 2. Finally a fourth 180 degrees rotation completes 720

degrees of crankshaft movement.

This is an extremely compact engine, but dynamic

balance of this layout is poor, requiring an additional

counterbalance shaft.

2.6.5.

In-line Five-cylinder Arrangement

This arrangement has a power impulse every 720 degrees/5 i.e. 144 degrees of crankshaft

rotation. There are five crank-throws, all in separate planes spaced at an interval of 72 degrees

relative to each other. The crankshaft may have a main journal and bearing at each end and

between each pair of crankpins, making six-main-journal crankshaft. Alternatively, the main

journals between crankpins 1 and 2, and 4 and 5 may be removed with slightly reduced support

to provide a shorter four-main journal crankshaft. Firing-order is considered with the

crankshaft arrangement shown in Fig. 2.24.

With piston 1 at TDC at the end of compression stroke and about to begin its power stroke,

pistons 4 and 5 are at 72 degrees from TDC on their induction and exhaust strokes respectively.

and pistons 2 and 3 are at 36 degrees from BDC on their respective compression and power

strokes. Crankshaft rotation through 144 degrees brings piston 2 to the top compression stroke

and beginning of power, while pistons 3 and 5 are at 72 degrees from TDC on their respective

exhaust and induction strokes, and pistons 1 and 4 are at 36 degrees from BDC on their

respective power and compression strokes.

Fig. 2.23. “V four-cylinder arrangement.

At the end of second 144-degrees movement

of the crankshaft, piston 4 is at the top, complet-

ing compression and about to begin its power

stroke. Pistons 1 and 3 are at 72 degrees from

TDC on their respective exhaust and induction

strokes, and pistons 2 and 5 are at 36 degrees

from BDC on their respective power and compres-

sion strokes. At the end of third rotation of the

crank through 144 degrees, piston 5 reaches TDC,

to the end of compression and the beginning of its

power stroke. Pistons 1 and 2 are at 72 degrees

from TDC on their respective induction and ex-

haust strokes, and piston 3 and 4 are at 36

degrees from BDC on their respective compres-

sion and power strokes. A fourth 144-degree rota-

tion moves piston 3 to TDC on compression stroke

and about to start power stroke. Pistons 2 and 4 are then on their induction and exhaust strokes

respectively, and pistons 1 and 5 are on their compression and power strokes respectively. This

arrangement provides a firing order of 1,2,4, 5, 3. A final 144 degrees of rotation completes 720

degrees of crankshaft displacement

The spacing of the crank-throws through an odd number of five cylinders ensures, unlike

four-cylinder arrangement, that the pistons do not all stop and start together at the top and

bottom of each stroke. Therefore, this arrangement provides a very smooth drive.

2.6.6.

Six-cylinder Arrangement

A. In-line

A six cylinder in-line engine has a power

impulse every 720 degrees/6 i.e. 120 degrees of

crankshaft rotation. The crankshaft has six

crank-throws placed at 120 degrees out of

phase with one another, which can be arranged

only in three planes. Therefore, the crankpin

phasing is arranged in pairs (Fig. 2.25). For

heavy-duty diesel engines, seven journals and

bearings are provided, at each end and be-

tween adjacent crankpins. For petrol engines

only 4 or 5 main journals are provided. The

firing order with the crankshaft arrangement

shown in Fig. 2.25 is considered.

With piston 1 at the top of the compression

stroke, its opposite piston 6 is at the top of its

exhaust stroke. Rotation of crankshaft through 120 degrees brings pistons 2 and 5 to their TDC

and either one of these can be arrangement to complete a compression stroke. If piston 5 is

arranged to be at the end of compression and at the start of its power stroke, then piston 2 must

be on its exhaust stroke. Rotation of crankshaft through second 120 degrees positions pistons 3

Fig. 2.25. In-line six-cylinder arrangement.

fig. 2.24. In-line five-cylinder arrangement.

and 4 at the TDC, so either one of these can be on the compression stroke. If piston 3 is made

to be on compression, piston 4 must be on its exhaust stroke.

A third rotation of 120 degrees brings pistons 1 and 6 back again to TDC, where piston 6 is

arranged to be on the compression and piston 1, therefore, be on its exhaust stroke. A fourth

120 degrees rotation brings pistons 2 and 5 to their TDC. Piston 2 is now on its compression

and piston 5 on its exhaust stroke. Rotation of crankshaft through fifth 120 degrees brings piston

3 and 4 to TDC. Piston 4 is on compression and piston 3 on its exhaust stroke. Final rotation of

120 degrees completes the 720 degrees displacement of crankshaft and brings the pistons into

positions for the next cycle. This cycle provides a firing order of 1, 5, 3, 6, 2, 4.

If the phasing of paired crank-throws 3 and 4 and 2 and 5 are interchanged, then a second

equally suitable firing-order of 1, 4, 2, 6, 3, 5 is achieved. This arrangement provides excellent

dynamic balance and evenness of torque, and is preferred for engines larger than 2.5 liters

provided length is not a prime consideration.

B. Horizontally Opposed Flat

This six-cylinder engine has its three cylinders positioned in a horizontal plane on each side

of the crankshaft. The power impulses are timed as for the in-line six-cylinder arrangement

with every 120 degrees of crankshaft movement. The crankshaft has six crankpins spaced at 60

degrees intervals around the crankshaft. Normally five main journals and bearings are used .

Pairs of pistons, one from the each side of the bank reaches TDC and BDC simultaneously (Fig.

2.26). Similar to the in-line six-cylinder engine, this arrangement is extremely well balanced,

but its flat wide configuration makes it difficult to install at the front or rear of the car.

Assume pistons 1 and 2 at TDC with piston 1 at the end of compression and about to start

power stroke and piston 2 at the end of its exhaust stroke.

Pistons 3, 4, 5, and 6 are then at 60 degrees from BDC on

their exhaust, compression, induction, and power strokes

respectively. When the crankshaft is rotated by 120

degrees, pistons 3 and 4 reach at TDC at the end of their

respective exhaust and compression strokes. Pistons 1, 2,

5 and 6 are then at 60 degrees from BDC on their respec-

tive power, induction, compression, and exhaust strokes.

The order of firing at this point is 1, 4.

A second 120 degrees movement places pistons 5 and

6 at TDC, completing compression and exhaust strokes

respectively. Pistons 1, 2, 3, and 4 are then at 60 degrees

from BDC on exhaust, compression, induction and power

strokes respectively. The order of firing becomes 1,4,5. A

third 120 degrees rotation positions pistons 1 and 2 at

TDC again, completing exhaust and compression strokes

respectively. Pistons 3, 4, 5, and 6 are then at 6 degrees

from BDC on compression, exhaust, power, and induction

strokes respectively. The order of firing at this point is 1,

4, 5, 2,

A fourth 120 degrees rotation places piston 3 and 4 at TDC again, completing compression

and exhaust strokes respectively. Pistons 1,2,5, and 6 are then at 60 degrees from BDC on their

Fig. 2.26. Horizontally opposed flat

six-cylinder arrangement.

induction, power, exhaust and compression strokes respectively. The order of firing becomes 1,

4, 5, 2, 3. A fifth 120 degrees rotation brings pistons 5 and 6 to TDC again, completing exhaust

and compression strokes respectively. Pistons 1, 2, 3, and 4 are then at 60 degrees from BDC

on compression, exhaust, power, and induction strokes respectively. The complete firing order

is 1,4,5,2,3,6. A final rotation of 120 degrees completes 720 degrees of crankshaft displacement

making ready for next cycle to begin.

C. 60 Degrees *V Six-cylinder

In this layout the cylinders fire at equally spaced intervals of 120 degrees. The cylinders are

located with numbers 1,2, and 3 in the left-hand bank and numbers 4, 5, and 6 in the right-hand

bank. The crankshaft uses six crankpins to support the shaft, equally spaced at intervals of 60

degrees and arranged to lie in three planes. There are four main journals and bearings placed

at each end and between pairs of crankpins to support the shaft, thus providing a relatively

short but rigid construction (Fig. 2.27). The dynamic balance is relatively good providing a short

compact engine compared with the in-line six-cylinder arrangement.

Four firing orders are possible, but three of these involve consecutive firing of three cylinders

in each bank and only the fourth enables cylinders to be fired alternatively from each bank

having a firing order as 1, 4, 2, 5, 3, 6. This arrangement also offers the best selection from the

torsional vibration consideration. With this arrangement, pairs of pistons in different cylinder

banks are at the top of their strokes.

Consider pistons 1 and 5 are at TDC after compression and exhaust strokes respectively so

that piston 1 is about to start its power stroke and piston 5 in its induction stroke. A120 degrees

rotation of the crankshaft brings pistons 3 and 4 to the top of exhaust and compression strokes

respectively. At this point, the order of firing is 1, 4. A second rotation of 120 degrees positions

pistons 2 and 6 at TDC on compression and exhaust

strokes respectively. The order of firing at this point

is 1, 4, 2.

A third 120 degrees rotation places pistons 1 and

5 at TDC on exhaust and compression strokes respec-

tively so that at this point the order of firing is 1,4,

2, 5. A fourth 120 degrees rotation of crankshaft

positions pistons 3 and 4 to TDC on compression and

exhaust strokes respectively. The order of firing be-

comes 1, 4, 2, 5, 3. A fifth 120 degrees of rotation

brings pistons 2 and 6 at the top of exhaust and

compression strokes respectively. The final order of

firing is therefore 1,4,2,5,3, 6. The next 120 degrees

rotation completes 720 degrees of crankshaft dis-

placement so that ready for the next cycle of events.

2.6.7.

Eight-cylinder Arrangement

A. In-line Straight

This arrangement has a power impulse every 720

degrees/8 i.e. 90 degrees of crankshaft movement.

The crank-throws are spaced at intervals of 90

degrees to each other in the order the power impul-

Fig. 2.27. Vsix-cylinder arrangement.

ses intended (Fig. 2.28). There can only be four relative angular positions. Therefore, the

crankpin phasing is arranged in pairs and hence the crank-throws lie in two planes. Five or

nine main journals are required to support the crankshaft. The layout presented in the figure

resembles a four-cylinder crankshaft in one plane with twin cranks at either end forming a

second plane at right angles to the first. This arrangement is sometimes known as a split four

inline eight.

Let pistons 1 and 8 are at TDC, with piston 1 at the end of compression about to fire and

piston 8 at the end of its exhaust stroke. Pistons 3 and 6 are at mid-stroke on their respective

exhaust and compression strokes ; pistons 2 and 7 at BDC at the end of induction and power

strokes respectively; and pistons 4 and 5 at mid-stroke on their respective power and induction

strokes.

Rotation of the crankshaft through 90 degrees positions pistons 3 and 6 at TDC at the end

of exhaust and compression strokes respectively. Pistons 2 and 7 are then at mid-stroke on their

respective compression and exhaust strokes ; pistons 4 and 5 at BDC at the end of power and

induction strokes respectively; and pistons 1 and 8 at mid-stroke on their respective power and

induction strokes. The firing order at this positon is 1, 6.

A second 90 degrees rotation of crankshaft provides the firing order at this positon as 1,6,

2. Third degrees rotation position gives the firing order as 1, 6, 2, 5; fourth 90 degrees rotation

position as 1, 6, 2, 5, 8 ; fifth 90 degrees rotation position as 1, 6, 2, 5, 8, 3 and sixth 90 degrees

movement positon as 1, 6, 2, 5, 8, 3, 7. The seventh 90 degrees movement completes the firing

orders after 630 degrees rotation as 1, 6, 2, 5, 8, 3^ 7, 4.

A further 90 degrees movement makes

a total of 720 degrees, and completes two

crankshaft revolutions or four strokes in

readiness for the next cycle to begin. By

arranging different pairs of crank-throws,

other firing orders have been used in the

engines are 1, 5, 2, 6, 4, 8, 3, 7 and 1, 7, 3, 8,

4, 6, 2, 5.

To have extra capacity to pull large

loads, the crankshaft may be extended with

two more cylinders. This design though is

dynamically balanced there can be torsional

vibrations problem and also the extended

length may be difficult to accommodate in

some trucks.

B. 90 Degrees *V Eight with Single-plane Crankshaft

Similar to the two-plane crankshaft of the in-line eight-cylinder, the single-plane layout

used for the V-eight provides a power impulse every 90 degrees of crankshaft rotation. The

single-plane crankshaft uses four crankpins paired to have both outer and both inner crankpins

in phase. Each crankpin carries two connecting rod big ends, and normally five main journals

are used to support the crankshaft (Fig. 2.29).

Fig. 2.28. In-line straight eight-cylinder arrangement.

Fig. 2.29. 90 degrees V eight-cylinder

arrangment with single-plane crankshaft.

Let pistons 1 and 4 remain at TDC, with piston 1

at the end of compression and about to fire, and piston

4 at the end of its exhaust stroke. Pistons 2 and 3 are

then at BDC at the end of power and induction strokes

respectively ; pistons 5 and 8 are at mid-stroke on

exhaust and compression strokes respectively ; and

pistons 6 and 7 are at mid-stroke on induction and

power strokes respectively.

A first, second, third, fourth, fifth, and sixth 90

degrees rotation of crankshaft provide the firing order

in their respective positions as, 1, 8; 1, 8, 3; 1, 8, 3, 6 ;

1, 8, 3, 6, 4 ; 1, 8, 3, 6, 4, 5 ; and 1, 8, 3, 6, 4, 5, 2. The

final firing order is completed after 360 degrees of

rotation i.e. seventh 90 degrees movement of the

crankshaft and is 1, 8, 3, 6, 4, 5, 2, 7.

An eighth 90 degrees of rotation completes 720

degrees of crankshaft movement of four-stroke cycle

and in readiness for the next cycle of events.

The single-plane crankshaft, unlike the two plane

V-eight crankshaft, provides at least 180 degrees ex-

haust pulse intervals between adjacent cylinders, and

with single manifold modification this can be extended

to 360 degrees before pulse interference can occur.

C. 90 degrees *V Eight-cylinder Arrangement

with Two-plane Crankshaft

This arrangement of cylinders provides the firing at

equally phased intervals of 90 degrees. The cylinders are

arranged with numbers 1, 2, 3, and 4 in the left-hand

band and numbers 5, 6, 7, and 8 in the right-hand band

as shown in Fig. 2.30. The two-plane crankshaft uses

pairs of crank-throws phased at intervals of 90 degrees.

Each crankpin incorporates two separate connecting-

rods, hinged to pistons in different cylinder banks. A

main journal and bearing is provided at each end and

between adjacent crankpin. Since two connecting-rods

share a common crankpin these five-main-journal-

crankshafts are extremely short and less complicated.

The two-plane crankshaft has a dynamic balance far

superior to that of the single-plane crankshaft and hence

is more popular.

Consider the order of cylinder power strokes occur-

ring as the crankshaft rotates as shown in the Fig. 2.30.

With piston 1 at TDC after its compression stroke and at

Fig. 2.30. 90 degrees V eight-cylinder

arrangement with two-plane crankshaft.

the beginning of the power, piston 5 is at mid-stroke on compression. Piston 3 and 7 are then at

mid-stroke exhaust and at the beginning of exhaust respectively; pistons 4 and 8 are at the

beginning of the compression and at mid-stroke on induction respectively; and pistons 2 and 6

are at mid-stroke power and at the beginning of induction respectively.

With subsequent first, second, third, fourth, fifth, sixth and seventh 90 degrees of rotations

of the crankshaft provide the firing order in this case as 1, 5, 4, 8, 6, 3, 7, 2. A final eighth 90

degrees of rotation completes 720 degrees of crankshaft displacement.

2.6.8.

Twelve Cylinder Arrangement

These engines are originally designed for aeroplanes. But some cars like Rolls Royce,

Packard, Lincoln Zephyer and Daimler “Double” Six have also employed these engines. These

provide a much superior torque and perfect dynamic balance, but have extra complication and

expense of manufacture.

Essentially the twelve-cylinder arrangement consists of two sets of six-cylinder in-line with

each forming a bank inclined at 60 degrees or 75 degrees. They use a common crankshaft

and camshaft with six sets of forked and plain connection rods. The engine employs a pair of

magnetic coil ignition units, two circulating pumps, and two carburettors for best results. These

engines have a firing order of 1, 4, 9, 8, 5, 2, 11, 10, 3, 6, 7, 12. The Italian Ferrari is the only

car, which is being manufactured with a twelve-cylinder engine.

2.6.9. Sixteen Cylinder Arrangement

These engines have two sets of straight eight-cylinders inclined at an angle or “V and are

perfectly balanced. This engine operates smoothly due to a continuous flow of power through

eight power impulses equally spaced for every revolution of the crankshaft. The firing order of

the cylinder arrangement is 1, 4, 9, 12, 3, 16, 11, 8, 15, 14, 7, 6, 13, 2, 5, 10. The Cadillac car

uses this engine and has the specifications of bore and stroke 88.9 mm each, cylinder capacity

7060 cc and produces 136 kW at 3600 rpm. The cylinders, arranged in two banks of eight

cylinders each, are inclined at 135 degrees. A single casting includes both cylinder banks and a

greater part of the crankcase. Hydraulic compensating types of valve tappets are used for

automatically maintaining the correct clearance.