Chemistry Reference

In-Depth Information

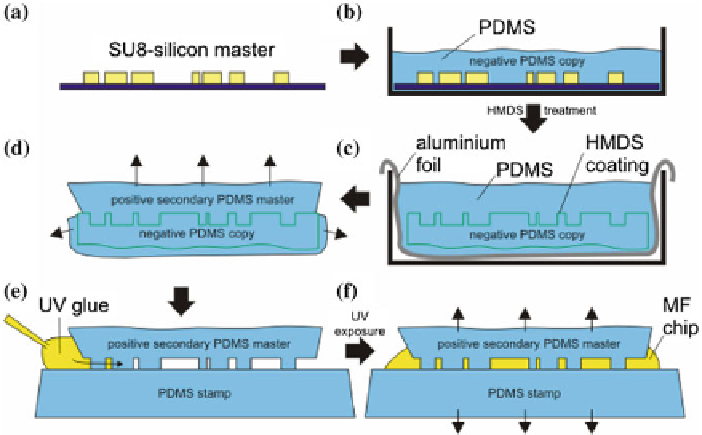

Fig. 4.2

To protect the SU8 masters (

a

) a three step copying technique is used for the microfluidic

chip production. After preparing a negative PDMS copy of the channel structure (

b

) its surface is

treated with HMDS and a secondary (positive) PDMS master is taken (

c

). This secondary master

is separated from the surrounding PDMS (

d

) and placed on a flat PDMS stamp (

e

). The spaces in

between are filled with UV curable glue and after 5-10min of UV light exposure the microfluidic

chip can be peeled off (

f

)

a few hundred micrometers assuming a planar orientation, i.e. no curvature, of the

film. Nevertheless, these reconstituted membranes also show the drawback that the

Plateau Gibbs border (PGB), the oil containing reservoir surrounding the membrane

patch, will always be in the path of the X-rays. Due to the strong diffractive index

contrast between the water and the PGB it is likely to give an additional contribution

to the diffraction pattern. This is expected to make the theoretical modeling more

complicated—however, for the work shown here, we do not yet include this effect

into the model. It must be noted that this is not the case for the bulged interface of

the BLMs where the theoretical modeling of the interface is thus less complicated.

4.3 Results

4.3.1 Phase Contrast Imaging Model

Quantitative structural and dynamical studies of microfluidic lipid membranes were

performed by using a direct imaging method, namely propagation based X-ray phase

contrast imaging (PCI). To this end a simplified model is introduced that explains