Environmental Engineering Reference

In-Depth Information

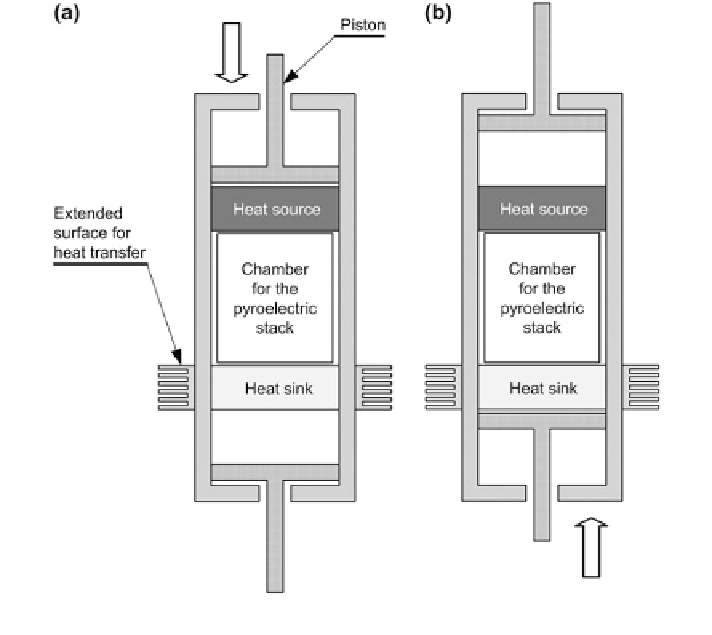

Fig. 10.22 Pyroelectric energy converter that employs regeneration (see also Olsen et al. [

67

])

effect of the cyclic frequency and the temperature of the heat source on the power

density of the device were investigated. The maximum power density output

achieved was approximately 135 W/L of the pyroelectric material with the fol-

lowing parameters: a heat sink temperature of 40

°

C, a heat source temperature of

eld of 20 MVm

−

1

, a high electric

eld of 50 MVm

−

1

and a

100

°

C, a low electric

frequency of approximately 1 Hz.

In 1981 Olsen et al. [

67

] suggested that in order to increase the ef

ciency of a

pyroelectric energy converter, a heat regeneration process should be employed.

Based on this idea they designed the device that is schematically presented in

Fig.

10.22

. The device consisted of a stack of pyroelectric elements, an electrical

heater (heat source), an aluminium block (heat sink), a Te

uid

pumping system. The pyroelectric stack was put in the housing, which was then

fl

on housing and a

fl

lled with silicone oil. The silicone oil was pumped from the heat sink to the heat

source in an oscillatory manner, creating temperature oscillations in the pyroelectric

elements. To pump the

uid, a piston driven by an electrical motor was used.

Furthermore, in order to achieve the pyroelectric Ericsson cycle, the applied voltage

was controlled as well. The voltage was changed from the low value to the high

value after the piston had moved the

fl

fl

uid from the heat source to the heat sink,

Search WWH ::

Custom Search