Environmental Engineering Reference

In-Depth Information

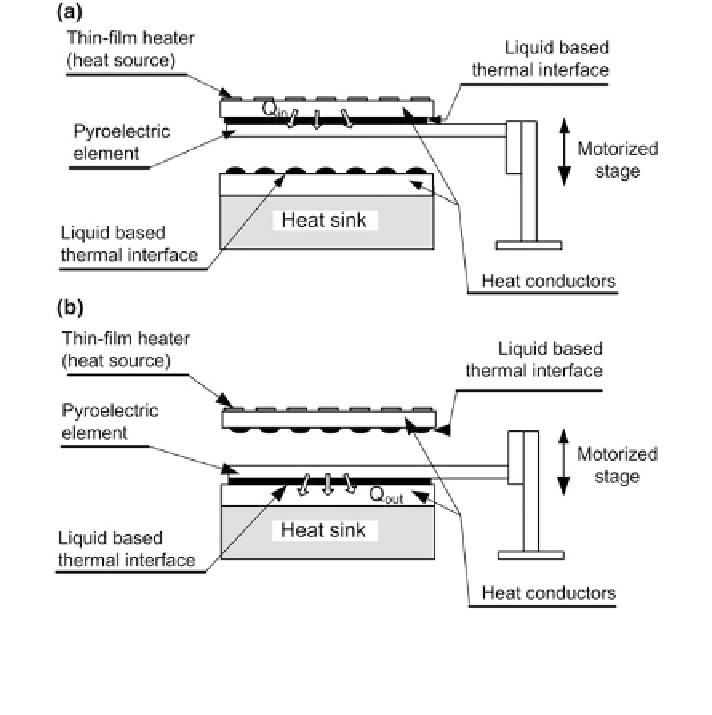

Fig. 10.21 Pyroelectric energy harvesting device using liquid-based switchable thermal interfaces

working according to the pyroelectric Ericsson cycle, a The pyroelectric material is in thermal

contact with the heat source, b The pyroelectric material is in thermal contact with the heat sink

(see also Cha et al. [

80

])

copolymer material with pyroelectric properties. The pyroelectric material had

electrodes on both sides and was positioned on a glass substrate for reasons of

mechanical stability. The glass substrate with the pyroelectric material (pyroelectric

element) was mounted on a motorized stage and positioned between the heat sink

and the heat source. The contact surfaces of the heat sink and the heat source were

covered with liquid-based thermal interfaces to enhance the heat transfer from the

pyroelectric element to the heat source/sink. The device works in accordance with

the following description. First, the pyroelectric element is moved into physical

contact with the heat source and therefore the material heats up (Fig.

10.21

a). Next,

the electric eld is switched to the low value. The pyroelectric element is then

moved into physical contact with the heat sink and the heat is transferred from the

pyroelectric element to the heat sink by means of heat conduction (Fig.

10.21

b).

The electric

eld is then increased and the cycle can be repeated. During the

experiment, the pyroelectric current and the applied voltage were measured and

based on these measurements the generated electrical power was calculated. The

Search WWH ::

Custom Search