Environmental Engineering Reference

In-Depth Information

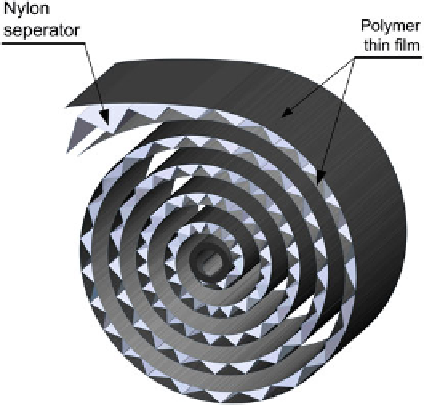

Fig. 10.23 Spiral stack made

of layers of polymer and

nylon separator (see also

Olsen et al. [

81

])

thereby heating up the stack of the pyroelectric material (Fig.

10.22

a). After the

fl

uid had been pumped from the heat sink to the heat source, thereby cooling down

the stack of pyroelectric elements, the voltage was decreased from the high value to

the low value (Fig.

10.22

b). The stack of pyroelectric elements was constructed

from Pb

0.99

Nb

0.2

(Zr

0.68

Sn

0.25

Ti

0.07

)

0.93

O

3

(PZLT) ceramic plates with dimensions

of 24

0.25 mm

3

. Wires were soldered to the electrodes of each ceramic plate

and 24 of such assemblies created a porous stack with a 0.25-mm gap between the

pyroelectric elements. The electrically wired pyroelectric stack was connected to a

measurement system to measure the generated pyroelectric current and the voltage.

Based on the measured current and the voltage, an electrical energy of

0.31 J

×

×

24

cycle

−

1

/L of the pyroelectric material) was calculated. The

temperatures of the heat source and the heat sink were 178 and 145

cycle

−

1

(130 J

·

·

°

C, respec-

eld was varied between the high value of 3.2 MVm

−

1

and

the low value of 0.4 MVm

−

1

. The frequency of the device was 0.128 Hz and the

electrical power output was 40 mW. The heat input of the electrical heater was

9.6 W and, accordingly, the ef

tively, and the electric

ciency of the device was 0.42 %.

Olsen et al. [

81

] performed an additional experiment, similar to the one

described above; however, in this case a polymer pyroelectric material P(VDF-

TrFE) was used. The polymer material was formed in a spiral stack that was

constructed from layers of the polymer pyroelectric material. Between the layers of

the polymer material a nylon separator was inserted to create a void for the

fl

uid

fl

ow (Fig.

10.23

). The results of the experiment showed that in comparison with the

PLZT-based pyroelectric stack, the produced electrical power of 30 J

cycle

−

1

/L of

the pyroelectric material was almost an order smaller. The temperatures of the heat

sink and the heat source were 23 and 67

·

°

C, respectively, and the electric

eld was

varied between approximately 22.5 and 53 MVm

−

1

.

Search WWH ::

Custom Search