Chemistry Reference

In-Depth Information

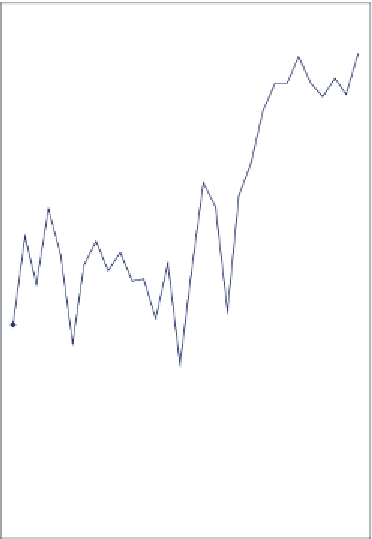

Because all of the points are within three standard deviations, we expect

that we are just seeing normal process deviations. If we plot historical values

for the process, we should see that they typically fall within upper and lower

limits similar to the upper and lower limits calculated by taking the mean

±

3 standard deviations. We can use this charting method to use statistical

process control. We do this by setting guidelines for control of the process.

One guideline might be that no adjustments should be made if the process is

“in control”. We can define “in control” as no sample points outside of the

limits (can use either the process limits from historical data or the calculated

limits); most points near average; similar number of points above andbelow

average; and a random distribution of points.

If we accept these control limits and continue to run the process without

adjustment, checking again after 10 more shifts, we see the control chart

(Figure 13.11). The process is out of control. Beginning with sample 22,

60

58

Upper control limit

56

54

52

50

48

46

Lower control limit

44

42

40

024681012141618202224262830

Sample #

Figure 13.11

Process with Samples above Upper Control Limit

Search WWH ::

Custom Search