Chemistry Reference

In-Depth Information

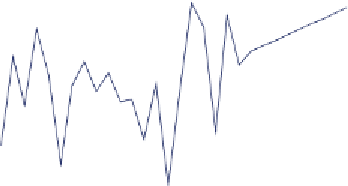

60

58

UCL

56

54

52

Mean

50

48

46

LCL

44

42

40

024681012141618202224262830

Sample #

Figure 13.12

Process with Samples not Randomly Distributed

we are above the upper control limit. That shift should have taken corrective

action and made adjustments.

What if the next ten samples had looked like the next chart (Figure 13.12)?

All the data points are within the control limits, but the process is not in

control. The points are not randomly distributed, and there are not a simi-

lar number of points above and below the mean. Corrective action should be

taken. This also began around shift 22 but the trend would probably not be

recognized until several more samples had been tested.

One of the advantages of control charting and statistical process control

is that everyone seems to understand the use and it can be a tool to improve

process consistency. With a set of rules, it can be used to prevent excessive

“tweaking” of a process which can cause increased variability and therefore

decreased quality. It can also give increased process understanding. In the

previous two examples, something changed around shift 22. By going back

through the data logs, the process engineer can often gain an understanding

Search WWH ::

Custom Search