Information Technology Reference

In-Depth Information

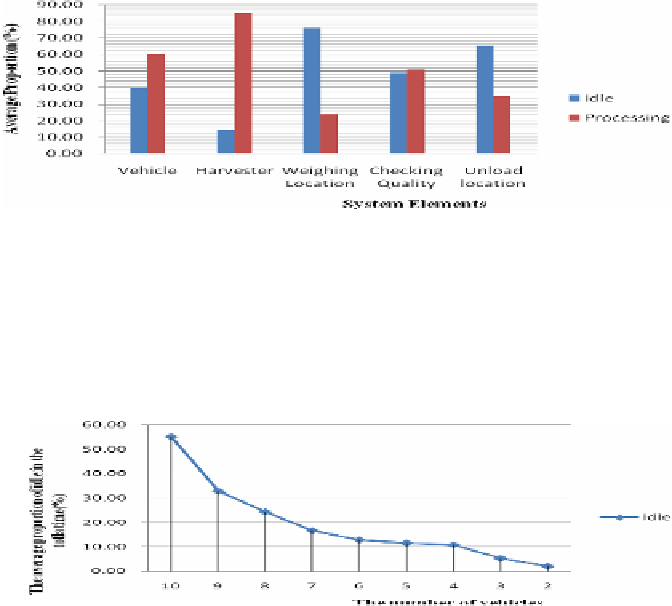

variables. Figure 1 shows that the harvester is busy that processing time is more than

idle time and the weighing location is idle most of time, and the checking quality is

basically same leisure and working time, so it is considerable to combine the weigh

location and checking quality. The unload location idle time is more than processing

time due to there are four unloading location in the company which means four

warehouse doors used.

Fig. 1.

The average time proportion of vehicle, harvesters, and company working lacation

The productivity of loading is grown in the experiments by changing the loading time

from normal (10, 2) to normal (5, 1), which is available by using advanced loading

equipments. Figure 5 shows the idle rate variety with the reducing number of trucks.

Fig. 2.

The idle rate variety with the reducing number of trucks

Figure 2 shows that the proportion of idle in the total time reduced sharply when

the method of transportation changed from one vehicle charge one field to dispatcher

managing vehicles, the idle rate drop from 55.05 to 32.8. Whereas in the model

running process the vehicle working time are imbalanced, that one start to transport

only when the other vehicle is busy working, so continue to reduce the number of

vehicles. When the number of vehicle reduced to four all the vehicle run at the same

time and the idle rate is 10.86%. When the number of vehicle reduced to 3 there is

flow-item blocked occurred. So there are 4 trucks appropriate configuration for

company to transport rapeseed from 10 different fields. According this proportion, 10

trucks can meet the transport requirement of 25 contract farmers of the plant located

within 30km.

Search WWH ::

Custom Search