Hardware Reference

In-Depth Information

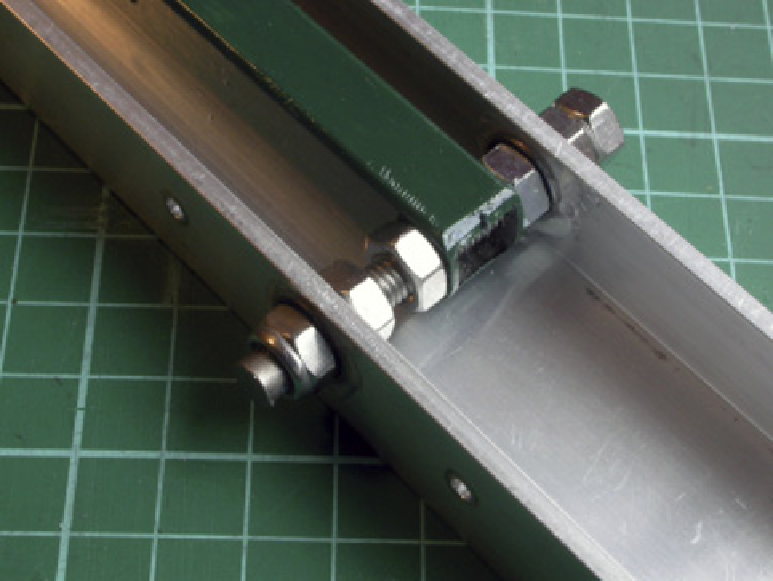

Figure 16-9:

Fixing the

pendulum to the

threaded rod

and channel.

The magnets are extremely powerful and can be prone to damage. Never let them ly together,

no matter how tempting it is. This is because they come together with such force that they

will shatter and small pieces will chip off them. This can happen the very irst time they come

together. Another thing is that strong magnets can pick up iron ilings in a workshop. You need to

remove those to get a uniform magnetic ield. I have found the best way is to use

blue tack

- the

sort of putty used for ixing posters to a wall. Use this to mop up a magnet of ilings and then

throw the piece away. Better still - do not let ilings get onto the magnet in the irst place.

Smooth Swinging

he bearings I used were the type MR126 sealed, which are quite low cost and are widely used

in the construction of 3D printers, inline skates and tools. hey have a 6 mm hole for the

threaded rod and are 12 mm in diameter. I drilled each side of the channel with a 12 mm drill

and used a vice to push the bearings into the hole. his produced a nice interference it. At irst

this appeared to work well, but as the threaded rod was tightened up I noticed that there were

sections of the rotation that appeared stif. So in order to exactly align them I iled one hole so

that it was slightly larger, allowing a very small amount of slack all around, and then I tightened