Hardware Reference

In-Depth Information

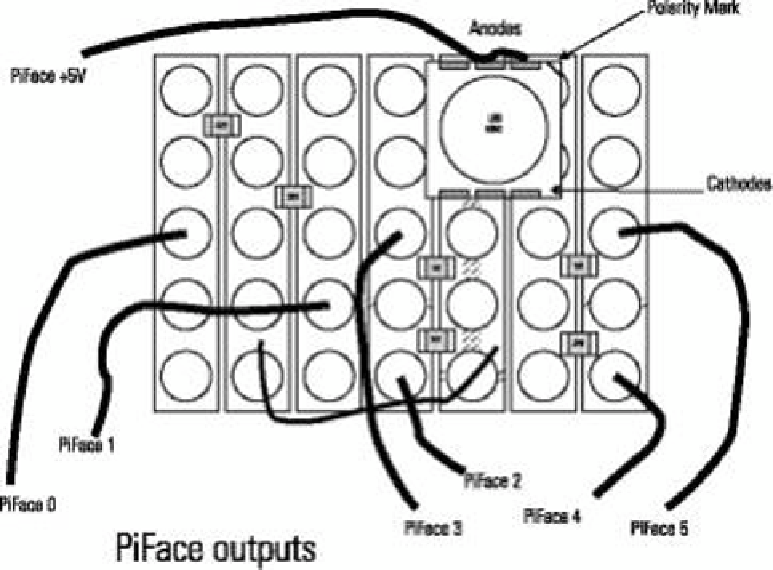

Next you need add the components. Figure 8-7 shows how they are arranged. You need a ine

pair of tweezers and a magnifying glass. Take the 5050 LED and make sure that the polarity

mark is at the top. It marks the three anodes; if you are not sure, use the multimeter test tech-

nique described earlier. he critical point is to line things up so that the left-most two anode

connections connect to diferent strips of the half strip you have cut out. Now remove the LED

and just put the smallest dab of solder on the strip board where the left cathode connection is

going to be. Now with your iron in one hand and the tweezers with the LED in the other, align

the LED again and touch the iron on the solder. Position the LED lat on the board and then

remove the iron. Keep the LED still while the solder sets. Now check that it is aligned correctly.

If not, reapply the iron and straighten it with the tweezers. Only when you are sure that it is

positioned correctly apply solder to the other connections. he anodes should be joined

together by applying suicient solder so that the two tracks are bridged.

Figure 8-7:

Circuit layout

using surface

mount

components.

Now you need to add the resistors. You could use through hole at this point, but you might

as well go for surface mount. A surface mount resistor should sit nicely between the tracks of

0.1˝ pitch strips. Note how surface mount resistors are labeled. hey use three numbers: he

irst two are actual numbers, and the third one says how many zeros there are. So a resistor

marked “471” is 470 ohms. here are two sizes that will do this: he larger is known as

0806,

and the smaller as

0604;

either size will do. (I used the smaller resistor size.) A photograph of