Hardware Reference

In-Depth Information

However, for a much better result, you can use surface mount components. Not only will

this be smaller, but the light output also will be latter and more even, producing a much bet-

ter distributed level of colour. Surface mount can be a bit scary, but it is not as diicult as you

might think. Despite the fact that the RGB LED I used is not the right pitch for the strip

board, you can easily make it it using a scalpel or sharp knife.

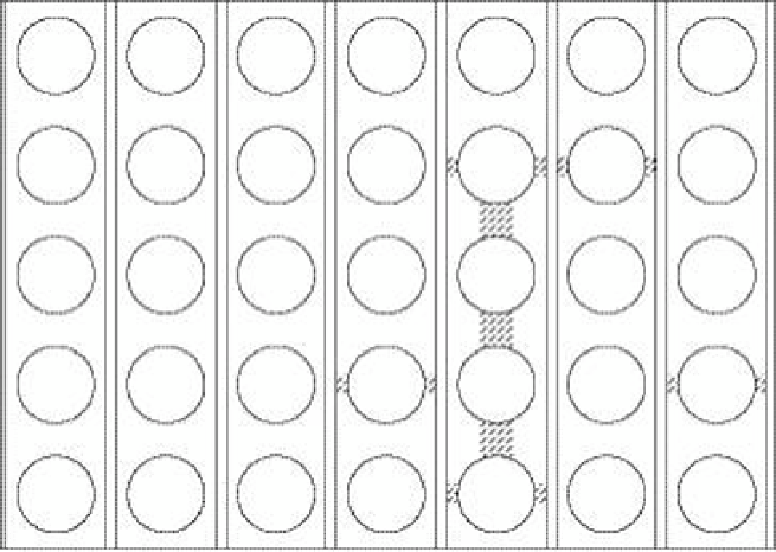

Start of with a piece of 0.7˝ by 0.5˝ strip board with the strips running vertically, as shown in

Figure 8-6. here are some shaded parts in Figure 8-6 that show the area where you are going

to remove the copper. here are two types of cuts you need to make - from the hole to the

edge of the strip and between holes. he irst is the easiest; simply put the point of the knife

in the hole and put the blade at an angle touching the side of the track. With a rotary wrist

movement, cut the copper. his will leave a lake of copper standing up. Remove this by

repeating the action from the other direction, and remove the copper. You need to do this on

both sides of the hole to break the connection.

Figure 8-6:

Cutting out

some of the

copper on a strip

board to make

the LED it.

here are ive holes to cut like this. he next cut is to remove a strip of copper between the

holes. Start with your blade in the hole and score down to the next hole. Repeat this for the

other side of the hole. hen use the blade and lift out the copper between the two score

marks. his sounds complex when written down, but it is actually quite easy to do. In the end

you will have split one of the 0.1˝ copper strips into two 0.05˝ spaced strips.