Biomedical Engineering Reference

In-Depth Information

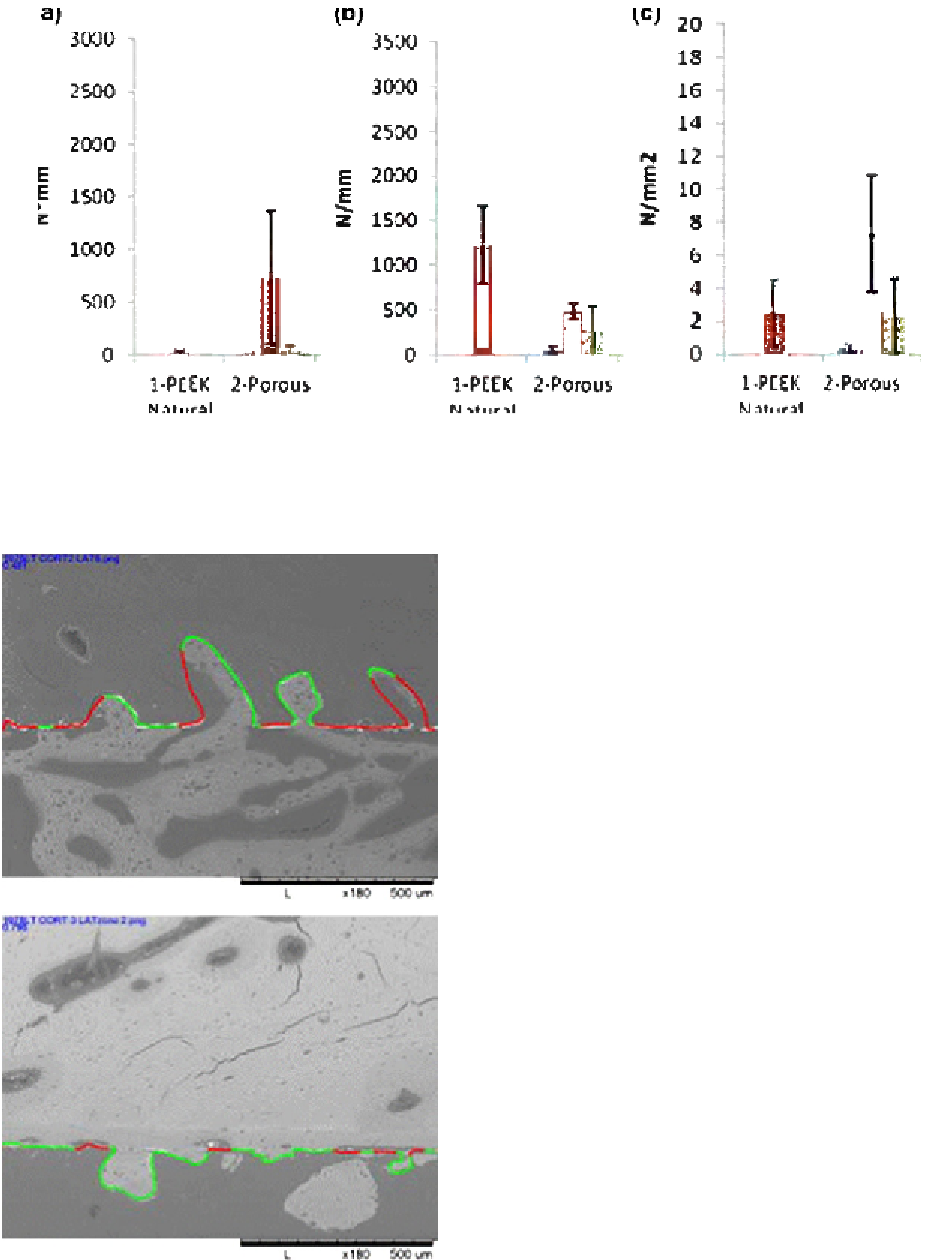

Figure 12.5

Showing the energy to failure (a), stiffness (b), and maximum shear (c) required for solid or porous PEEK

samples at 4 weeks for aged sheep (blue), 12 weeks for aged sheep (red), and 4 weeks for 18-month sheep (green).

machined topography) could have subtle effects on

the adhesion and mineralization of osteoblasts

[31]

;

therefore, the difference in topography and the

presence of pores may provide an added benefit for

some situations. The porous PEEK here had a mean

pore size of 70

m

m when analyzed using CT.

Although the mean pore diameter achievable through

this technology was lower than the majority of

recommendations for osseoconductivity in other

materials

[33

e

35]

, the smaller diameter here proved

sufficient to confer some benefit. Although larger

pore sizes seem to be preferred for the current

orthopedic porous biomaterials (e.g., porous

tantalum or titanium) and has been cited as needing

to be larger than 50 to 150

m

m

[36]

, the smaller pore

sizes are present in other application areas such as

CMF (e.g., porous polyethylene). It has been reported

that this is sufficiently effective for fibrous and bone

ingrowth in facial implants

[4,5]

. This may not be

optimal for ingrowth into a hydrophobic polymer and

the material may not possess the mechanical prop-

erties for other applications but it does suggest that

porosity, whatever the size, confers some benefits.

Some researchers have suggested that the necessary

pore size may only be required to be sufficient for

vascularization of the tissue to occur since this then

allows the subsequent nutrients to be present to

permit tissue ingrowth

[37]

. The interconnectivity of

this porous PEEK material was sufficient to permit

some limited ingrowth at the surface interface, but

the bulk of the material possessed closed cells, which

(a)

(b)

Figure 12.6

Showing the determination of bone

ongrowth areas using MatLab analysis of radiographs.