Biomedical Engineering Reference

In-Depth Information

this may entirely depend upon application and

anatomical location of the implant. The presence of

porosity on the current PEEK samples affected the

mechanical properties, significantly reducing the

mechanical properties observed for solid PEEK.

However, this reduced modulus may be beneficial for

nonload-bearing applications or designs in combi-

nation with other supporting materials. When

osseoconductivity is not required, the porous PEEK

foam demonstrated a new set of mechanical proper-

ties that may be of use in the device designer's

toolbox when attempting to recreate different tissue

gradients. The positive in vivo results also suggest

that whilst the porosity created with this technology

is restricted, it may still be adequate to confer

a benefit and it is a process that has no adverse effect

on the PEEK feedstock material.

12.6 Case Study 2dComparison of

Small and Large Pore Sizes

Although the pore size in case study 1 was suffi-

cient to confer some beneficial properties towards

osseoconductivity, for this second case study inves-

tigation the porosity was increased to more accu-

rately represent the configuration of trabecular bone.

With the creation of larger pores and a more open and

interconnected porosity, the reduction in PEEK

structure will have implications for the retention of

strength. The porous metals that have achieved pore

sizes similar to that of trabecular bone (~700

m

m)

have the ability to retain sufficient mechanical

properties for orthopedic applications such as

augments or backing on acetabular cups. A porous

PEEK with porosity and structure similar to trabec-

ular bone is likely to possess mechanical properties

similar to actual trabecular bone. This naturally

means that the material must be treated as a bioma-

terial alternative to bone rather than an analog to the

porous metals. The benefits of creating a material

from PEEK mean that the material can be trimmed

and formed in situ and is radiolucent to permit

observation of any ingrowth, and that the look and

feel is like that of bone. In order for a porous PEEK to

meet both the ingrowth and strength requirements

that could be required to be consistent for predicates

in certain applications, it may be necessary to create

hybrid solid

e

porous materials.

To examine the matching of the porosity to

trabecular bone and the effect on mechanical

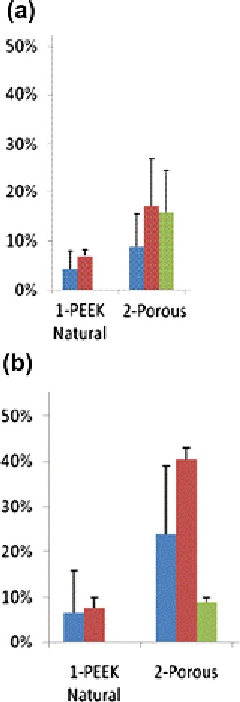

Figure 12.7

Percent implantecortical bone contact (a)

and percent implantecancellous bone contact (b) for

solid (PEEK natural) or porous PEEK. Percentages

increased over time for aged sheep from 4 weeks

(blue) to 12 weeks (red). Percentage was also influ-

enced by age, with comparable implantebone contact

present at 4 weeks duration for the 18-month sheep

(green). There was no significant difference between

solid or porous due to

n

¼

3.

were inaccessible by the surrounding tissue.

However, the extent of required porosity can be

debated since sufficient fixation may occur in the

superficial first millimeters of an implant surface and

presence of porosity further than this may make the

material more prone to the creation of dead-spots that

are isolated from nutrient transfer. The continued

presence of non-interconnected pores in the bulk core

of this material may also facilitate the transfer of

force vectors and aid in mimicking in vivo tissue.

For subsequent improvements in osseo-

conductivity, a mean pore diameter larger than

70

m

m and greater interconnectivity would be likely

more preferable for osteoblast ingrowth. However,