Hardware Reference

In-Depth Information

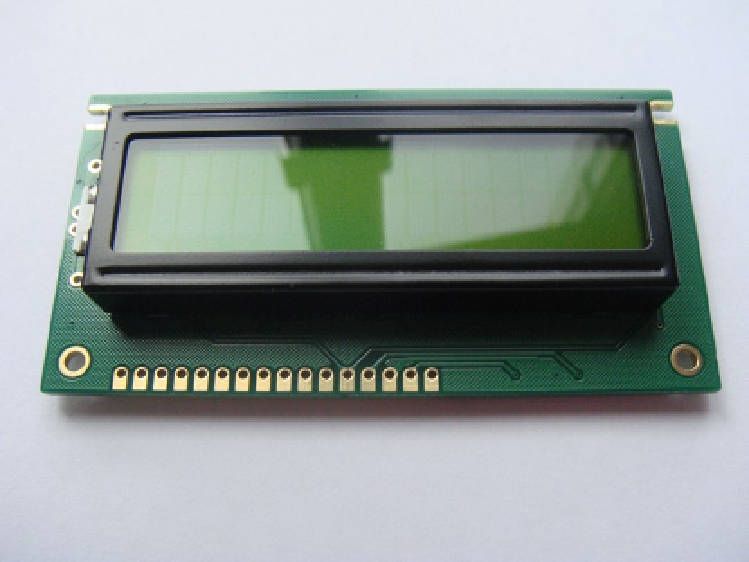

On my LCD, as you can see in Figure

4-2

, I have both pins 15 and 16 as well as anode and cathode solder pads on

the side solder pad for the backlight (you can see this on the left-hand side on the white pad). The pad configuration

on my LCD is one single row, which makes it quite easy to solder a pin header on.

Figure 4-2.

The front of a generic HD44780 display

If I flip the LCD over and take a look at the back of the printed circuit board (PCB), it appears that pins 15 and 16

may be connected to the anode and cathode of the LCD backlight. Now, you don't want to just guess it's connected, do

you? That's a perfect way to let the magic smoke out. This is where the ohm setting on your multimeter comes in real

handy. Remember that ohms are the measure of resistance. If you set your multimeter to the ohms setting and touch

the two probes together, what happens? You get a reading of zero. That means there is no resistance between each

probe. If you move the probes away, you will see the value rising back to a positive integer. This is called continuity

testing. With this in mind you can use continuity testing to measure the resistance between pins 15 and 16 and the

anode and cathode. Take a look at Figure

4-3

: you can see the pin out listing including pins 15 and 16. You will notice

that pins 15 and 16 have no label; I had to use my multimeter to figure out what they were connected to.