Environmental Engineering Reference

In-Depth Information

of natural rock with no visible support elements.

Rock surfaces with half-barrels after blasting,

anchors, bolts, steel mesh or shotcrete will not

be acceptable finish. Thus, it will be necessary to

apply some special treatments and surface finish-

ing techniques. These methods are the following:

- The excavation in all the space (cavern, light

shafts and entrance tunnel) will leave a skin

rock, at least 50 mm thick, between the excava-

tion and finished roofs and walls. This will sub-

sequently be cut off using a diamond wire to

create a smooth finished rock surface.

- all the permanent support (bolts and anchors)

will be countersunk with holes to a depth below

the finished surface to prevent being cut by the

diamond wire.

- The rock bolt and anchor holes will be reamed

with a thin-walled core barrel and the rock cores

will be retained.

- The threaded ends of the rock bolts will be used

to hold pulleys around which the diamond wires

will run.

- Discs of rock will be cut from the retained rock

cores and cemented into the reamed sections of

the rock bolt and anchor holes using a suitable

rock adhesive.

- The cavern and entrance tunnel loors will be

ground.

- Weathered dykes will be cut back, drained and

supported with a shotcrete or concrete infill.

- Discontinuities containing seasonal and long

term ground water flows will intersect the light

shafts and cavern walls. Drainage pipes will

not be permitted and the inflows and seepages

will need to be intersected and fully sealed with

grout.

- Finally, the cavern walls and roof will be cleaned

with high pressure water jets and geotextile will

be fixed to the finished surfaces and sprayed

with a resin coat. The geotextile and resin will

be used to secure the rock surfaces between the

anchors and rock bolts (steal mesh or shotcrete

are not aesthetically acceptable). if resin and

geotextile are not sufficient to support the little

blocks of rock, additional small (1 m long) rock

bolts (stainless steels pins) will be installed and

cement grouted. it is possible that resin and geo-

textile will not be required in the walls of the

space.

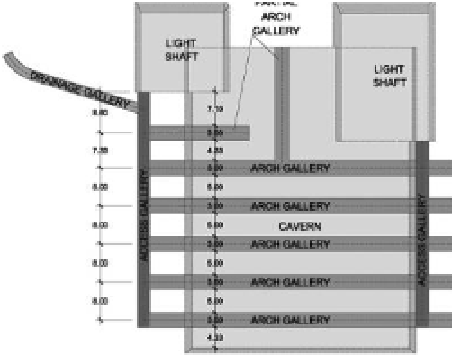

Figure 12.

Plan view of galleries above roof cavern.

subsequently, will be excavated the arch galleries

(3 m wide and 3.5 m high) between the access

galleries. a partial arch gallery will be also exca-

vated between the light shafts. all the muck will

be cleared through the pilot shafts to the pilot

gallery. a drainage gallery (2 m wide and 3 m

high) will be excavated from the mountain slope

- The support in the arch galleries will be installed

and operative before excavation of the cavern

roof starts.

- The cavern roof will be excavated as a series of

parallel headings from the light shafts and rock

bolts and anchors will be installed as the head-

ings are advanced.

- The remaining cavern volume will be excavated

as a series of benches and the constructor will

choose to simply remove the rock as spoil or

recover blocks for commercial use.

- The entrance tunnel will be excavated to full size

from the cavern to the portal.

explosives will not be permitted in the portals

areas (entrance tunnel and light shafts) to avoid

damage to the mountain slopes. The portal of

the entrance tunnel will be the unique access to

the works in the space in order to reduce envi-

ronmental problems in the mountain. although

mechanical excavation will be used in portals, the

underground works will be excavated using drill

and blasting techniques.

7

MoniToRinG

6

sPecial TReaTMenTs anD sURFace

FinishinG

The galleries above the cavern roof will remain

open to provide permanent access to the cavern

support and instrumentation points. The instru-

mentation will monitor the rock mass and ground

The artistic concept of chillida´s sculpture will

require that all the inner faces of the space will be