Environmental Engineering Reference

In-Depth Information

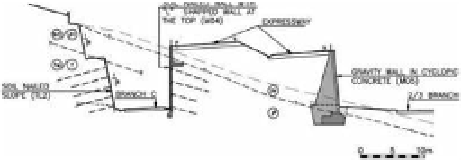

shallower slope deposits capable of being removal,

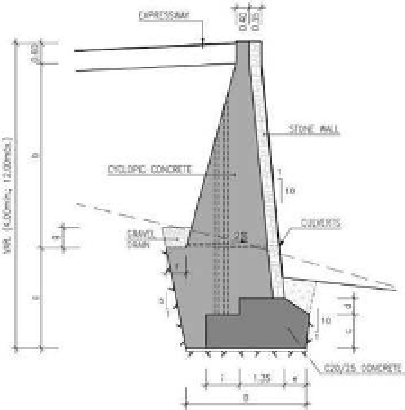

the option was made for gravity walls in cyclo-

pean concrete supported directly on the rock bed,

thus keeping wall deformation and consequently

embankment and road bed deformation at a mini-

mum. such structures offer the additional advan-

tage in that they are quickly and easily built and

their cost is lower than other structures of a similar

height, such as reinforced concrete walls. This solu-

tion was generally used for expressway structures,

since the route alignment runs along the base of

rocky cliffs where slope deposits are shallower,

as can be seen in the cross section shown in Fig-

ure 2. The height of this set of walls (M03, M05,

M12 e M22) (type and cross section can be seen in

Figure 3

)

varies between 4.0 and 12.0 meters.

Where it was necessary to make deep excavations

into the rock face and because of the geometry of

the route, required an inclination close to the verti-

cal, soil nailed walls were placed in order to protect

and stabilize the excavation. This is a fast, flexible

and low cost solution that takes advantage of the

resistance of the rock mass itself.

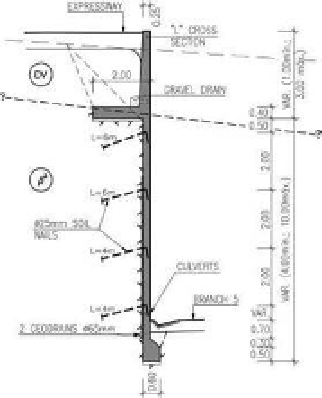

in locations where nailed walls were to be build

and where the road bed was at an elevation above

the top of the massif with a maximum difference

in elevation of around 3.0 meters, a reinforced con-

crete wall (l-shaped cross-section) was placed at

the top of the nailed walls to support the embank-

ments required to retain the road bed. This solu-

tion was only required in excavations associated

soil nailed walls (M01, M02, M04) with a

l-shaped section as shown in Figure 4 are made

up of a 0.25 meter thick reinforced concrete wall

poured directly onto the excavations face with

heights varying between 4.0 and 10.0 meters and

with 1 to 4 levels of nails using 4.0 to 6.0 meter

long, 25 mm diameter steel rods.

in situations where excavations of more than

3.0 meters were required in slope deposits and

where, on the one hand, the massif was located at

about the same elevation as the road bed and, on the

other, there were space limitations due to the prox-

imity to buildings at the top of the excavation, an

anchored wall solution was employed so as to con-

trol and limit deformations. The only anchored wall

included (M13) has a maximum height of 4.2 meters

and is made up of 2 rows of reinforced concrete

panels and 1 level of 480 kn capacity anchors.

The various branch roads are placed at eleva-

tions lower than the expressway as slope deposits

are quite a bit deeper making them impossible to

be completely removed so as to develop suitable

conditions for placing the foundations of the dif-

ferent retaining structures. Thus the structures

built in these locations required deep foundations

as illustrated in Figure 5.

Figure 2.

Typical cross section next to the base of the

slope.

Figure 3.

Gravity walls in cyclopean concrete.

Figure 4.

soil nailed walls with a l-shaped section wall

at the top.

3.1

Machico Sul Interchange

Where it was necessary to build retaining structures

for road bed embankments located in areas with