Biomedical Engineering Reference

In-Depth Information

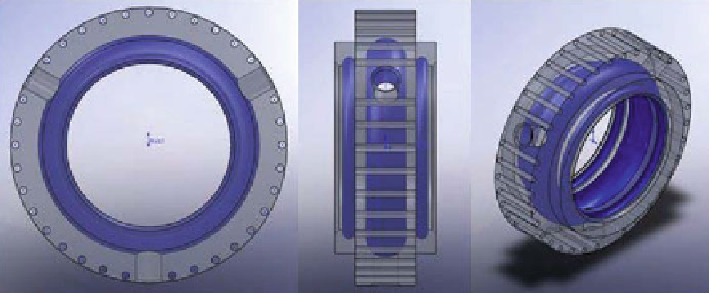

Fig. 7

Model for the second sensing ring built using Solid Works

The bigger holes on the outside of the ring are 120

ı

away from each other. These

holes are used to connect two N

2

O sensors and an air inlet to avoid creating a

vacuum in the system. Also, the main groove, coloured in blue, is bigger and now

round in section, instead of rectangular, as in the first model. This new format of

groove increases the volume were the gas will be circulating. On each side of it there

is a smaller and thinner groove where 'O' Rings can be fitted to seal the device, in

case there is a need to perform experiments with a completely sealed environment.

With the sensors connections placed 120

ı

apart it does not matter which

connector is attached to which hole as the relative angle between them will be

maintained. This would make the device much easier to use in a surgical situation

and also makes it easier to develop a control/recording measuring system.

The two thinner outer grooves in the testing ring were considered inappropriate

for further measurements due to the fact that, in the real situation there will always

be some gaps between the ring device and the real colon. This is because the colon

is a flexible surface, making it very difficult for a perfect attachment with a rigid

surface. In order words, it would be very difficult to avoid any leakage between the

device and colon during an actual surgical procedure. Therefore, a third model of

testing ring was created and a change was also made to the colon analogue. Figure

8

shows the third design in Solid Works (Fig.

9

).

The other change with this sensor ring is that the locating holes are now at 45

ı

intervals. This corresponds to the angles that it was decided should be studied.

Because the O-rings helped locate the “colon” centrally in the sensor ring, changes

were also made to the tube to ensure that the tube was centrally located. Some small

pads were fitted around the tube with gaps between them. The reason for the gaps

is due to the fact that in real life the sensing ring would not be perfectly attached

to the colon, and there would be always a certain amount of leakage between both

(Fig.

10

).

Lastly and one of the most important changes, was the introduction of two flow

control valves in the sensing inlet pipes. They are used to balance the volume of gas