Environmental Engineering Reference

In-Depth Information

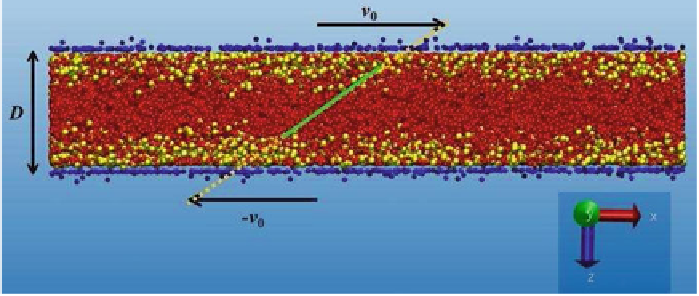

Fig. 11

A system configuration extracted directly from non-equilibrium computer simulations

using soft DPD interactions of polymer brushes grafted on soft DPD surfaces. The

blue

particles

are the grafted beads which move at constant speed

v

0

in the direction indicated by the

arrows

.

Those beads drag the rest of the beads forming the polymer chains (in

yellow

) to produce flow of the

solvent particles (in

red

). The

green line

indicates the velocity gradient as is expected in stationary

Couette flow. Adapted from Gama Goicochea et al. (

2014

)

enhanced oil recovery, for the design of improved rheology modifiers in the paint

industry, as well as lubricants, to mention a few. The idea behind non equilibrium,

stationary flow simulations for applications like those mentioned above is as follows:

two parallel plates are placed a certain distance apart, say in the

z

-direction; then

a constant force is applied to the top plate and an equal in magnitude but opposite

in direction force is applied to the bottom plate. This creates a velocity gradient (or

shear rate) which is responsible for creating a steady flow known as Couette flow. We

shall have more to say about the details of this type of flow in the next section, but

for now we focus on the use of soft DPD potentials in non-equilibrium simulations.

Although many works have been published that use computer simulations to study

Couette flow, most of them have been carried out using microscopic models, which

are accurate but are very time-consuming, even more than equilibrium simulations.

Recently, a study of the rheological properties of polymer brushes under theta solvent

conditions using only soft DPD interactions has been published (Gama Goicochea

et al.

2014

). The system consists of two parallel plates on the

xy

-plane, modeled as

soft DPD wall forces separated by a fixed distance

D

, where a number of polymer

chains were grafted at one of their ends and at grafting densities large enough to

form polymer brushes. A constant velocity

v

0

is applied to the grafted ends of the

polymer chains on the top and bottom plates, in opposite directions, so that stationary

flow is produced by the collisions of the chains with themselves and with the solvent

particles. This gives rise to a mean constant force

F

x

in each plate, in the stationary

regime. The grafted beads on the surfaces move with a constant velocity (

v

0

)but

there is a velocity gradient of constant shear rate

along the direction separating the

plates. Figure

11

shows a configuration of this system, extracted directly from the

simulations.

ʳ

Search WWH ::

Custom Search