Environmental Engineering Reference

In-Depth Information

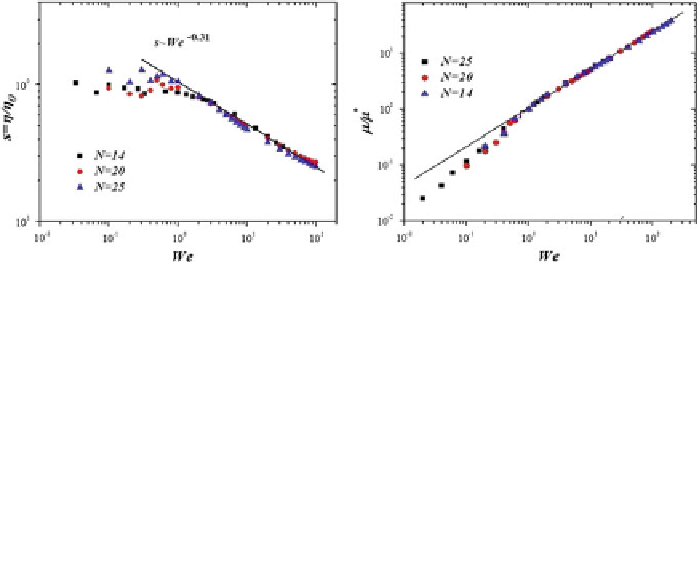

Fig. 12

(

Left

) Viscosity of the grafted beads of polymer chains forming brushes of three different

polymerization degrees, as a function of the applied shear rate. In order to use dimensionless units

on both axes, the

y

-axis was normalized with the limiting value of the viscosity at zero shear rate

ʷ

0

.

The

x

-axis was normalized with the value of the shear rate when the behavior of the applied force

changes from linear to sub-linear, so defining the Weissenberg number

We

.The

line

is the predicted

scaling law. (

Right

) The friction coefficient is normalized by its value at the transition from linear

to sublinear regimes, as a function of

We

. The friction coefficient for all brushes modeled obeys the

scaling law

μ/μ

∗

∼

We

0

.

69

. See text for details. Adapted from Gama Goicochea et al. (

2014

).

for fluids under flow,

as the one shown in Fig.

11

, using the following relation (Macosko

1994

; Pastorino

et al.

2006

):

One can calculate rheology properties such as the viscosity

ʷ

ʷ

=

F

x

( ʳ)

/

A

.

(16)

ʳ

In Eq. (

16

)

F

x

is the magnitude of the constant force in the

x

-direction, applied

to the planar surfaces of area

A

and

is the shear rate. The brackets represent an

average over the entire simulation time (Gama Goicochea et al.

2014

; Pastorino et al.

2006

). By changing the applied force one can vary the shear rate and then measure

the dynamic response of the fluid through the viscosity using Eq. (

16

). Newtonian

fluids are characterized by viscosities that are independent of the shear rate, but most

fluids of interests for modern applications, as well as the fluid simulated and shown

in Fig.

11

, are of the non-Newtonian type, namely they have viscosities that are shear

rate dependent (Macosko

1994

). Another rheological property of interest for polymer

brushes is the friction coefficient between the brushes and the fluid, which is given

by the following expression:

ʳ

μ

=

F

x

( ʳ)

F

z

( ʳ)

,

(17)

F

x

( ʳ)

F

z

( ʳ)

where

represent the mean forces that the grafted beads expe-

rience along the direction of the flow (

and

z

), respectively.

The brackets symbolize time averages over all the particles in the simulation box.

Clearly,

x

) and perpendicularly to it (

dž

dž

is a dimensionless number. Figure

12

shows the predictions for the vis-

cosity and the friction coefficient obtained from DPD simulations of Couette flow

for linear polymer brushes of varying polymerization degree under theta solvent

μ

Search WWH ::

Custom Search