Biomedical Engineering Reference

In-Depth Information

coatings such as apatite with bone compatibility are commonly used as coating phases,

and the Ti and its alloys are the metallic biomaterials mainly used as substrates. Since

these metals can be directly connected to living bone at an optical microscopic level (i.e.,

osseointegration),

(1,2)

they have been used as substitutes for hard tissues such as in stems

of artificial hip joints and dental implants for long-term implantation in bones.

(3,4)

Metallic

biomaterials should usually be fixed in the human body without being moved for more

than 3 months. A coating of bioactive calcium phosphate on Ti is applied for the stems

of artificial hip joints and dental implants to obtain a strong bonding with bones and to

shorten the fixation period.

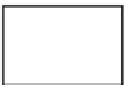

Surface Modification of Metallic Biomaterials

The surface modification processes for improving the bone compatibility of metallic bio-

materials are summarized in Figure 7.1.

(5)

They can be classified as dry and wet processes.

Morphology and/or phase/composition of the surface layer of metallic biomaterials are

modified in dry and wet processes by using ions/gases and solutions, respectively. The

phase/composition is controlled by applying an apatite coating or by modifying the sur-

face characteristics with nonapatite coating.

Vapor deposition can be used to apply apatite and other bioactive layers on metallic bio-

materials. Apatite coating on metallic biomaterials has been developed since the 1970s, and

plasma spraying has been clinically applied to apatite coating on Ti-6Al-4V implants since

the mid-1980s after FDA approval in 1981.

(6-8)

Although plasma spraying has a long history

of clinical applications in apatite coating due to the advantages of high deposition rates

with sufficiently low cost, more reliable coatings have been sought to improve the bonding

strength between the implants and the coatings while controlling the microstructure.

Phase/composition

Morphology

ermal spraying

Ti plasma spraying

Dry

process

Vapor deposition

Porous

Ion implantation

Blasting

Gas treatment

NaOH treatment

and heating

Blasting

+

Acid etching

Sol-gel

Dip coating

Biomimetics

Anodic oxidation

Electrochemical

deposition

Wet

process

Acid etching

No apatite formation

Apatite formation

FIGURE 7.1

Surface modification processes of metallic biomaterials.

Search WWH ::

Custom Search