Biomedical Engineering Reference

In-Depth Information

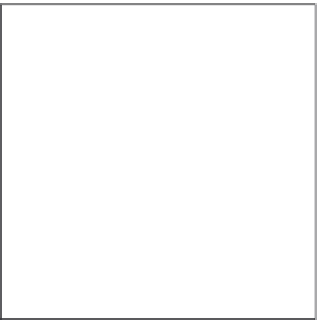

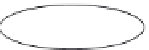

In order to develop more advanced bioceramic coatings on metallic biomaterials, many

calcium phosphate coating processes including vapor deposition, biomimetics, and elec-

trochemical deposition have been investigated.

(9)

These coating processes are shown in

Figure 7.2, where they are categorized by processing temperature and thickness of coating,

and also as to adherence and coating area.

(5)

Vapor deposition can be advantageous for the

preparation of uniform and dense coatings of calcium phosphate with a well-controlled

phase, composition, film thickness, and high bonding strength to metallic biomaterials.

Vapor deposition is generally classified into physical vapor deposition (PVD) and chemi-

cal vapor deposition (CVD). Both PVD and CVD are used to prepare solid films or pow-

ders from a gas phase. Although hybrid processes such as activated reactive evaporation

(10)

have been reported, chemical reactions in the gas phase are basically involved in the CVD

methods but not in the PVD methods. Ceramics are generally fabricated by powder sin-

tering with various additives due to their high melting points, covalent nature, low self-

diffusivities, and so forth. Vapor deposition techniques are suitable for the fabrication of

highly pure and dense ceramics at relatively lower temperature without additives. Typical

methods of PVD and CVD are summarized in Figure 7.3. The details of each method are

described in the next section. All the vapor deposition methods require energy for the

activation of source gases. The interaction between the particles (atoms/ions/clusters) and

solid surface changes depending on their kinetic energy as shown in Figure 7.4: deposi-

tion, sputtering, and ion implantation.

(11)

Sputtering as a PVD method utilizes the above-

mentioned phenomena of the kinetic energy of particles less than 10

3

eV for vaporization

of target materials and of the kinetic energy of particles less than 10 eV for deposition from

the gas phase.

PVD and CVD Methods

In PVD, a solid source material is physically vaporized by energy such as heat, plasma, or

laser, and then thin films are deposited on a substrate. Consequently, the composition of

1200

Good

IBD

Dip coating

900

Sputtering

CVD

CVD

Sol-gel

ermal

spraying

PLD

600

ermal spraying

Sputtering

PLD

IBD

Sol-gel

Biomimetics

300

Dip coating

Biomimetics

Electrochemical

deposition

Electrochemical

deposition

Poor

R.T.

0.1

1

10

100

1000

0.1

1

10

100

1000

ickness of coating,

t

(µm)

Coating area,

S

(cm

2

)

FIGURE 7.2

Processes for coating calcium-phosphate film on Ti substrate.

Search WWH ::

Custom Search