Environmental Engineering Reference

In-Depth Information

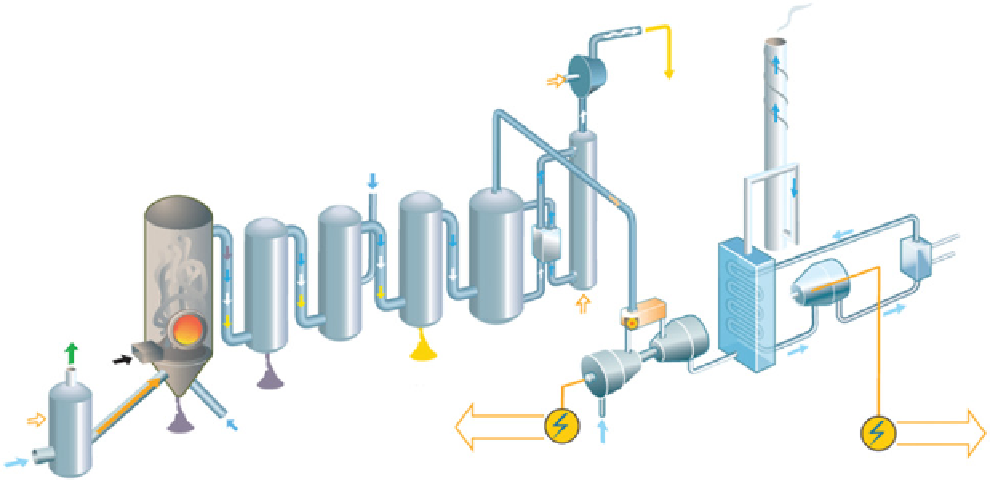

Precombustion (decarbonization) capture

CO

2

Water

vapor

(and

excess air)

Mechanical

energy

CO

2

desorber

Hydrogen

Sulfur

removal

Steam

Gasifier

Particle

remover

Cooling

water

Steam

condenser

Heat

Nitrogen

Fuel

Oxygen

CO

2

absorber

Shift

reactor

Gypsum

Heat

recovery

steam

generator

Gas turbine

Fly ash

Steam

Mechanical

energy

Electricity

Bottom ash

Air

Air

Air

separation

fiGure 21.8

precombustion schematic diagram flow. Courtesy from Ref. [17].

21.2.3

processes for Carbon Dioxide Capture

21.2.3.1 Precombustion Capture

Figure 21.8 shows the diagram of CO

2

removal using the precombustion process. The

system involves capturing CO

2

before burning the fuel. The fuel gas, liquid, or solid is first transformed into synthesis gas,

mainly CO and H

2

O, by reforming processes (for liquid and gaseous fuels) or gasification reactors (solid fuel). The latter

reaction is commonly called “partial oxidation” and proceeds according to reaction 21.1. The synthesis gas is cleaned to remove

particles that could damage the turbine or cause problems in subsequent steps of the process.

xy

+

CH HO CO

xy

x

+

x

+

H

(21.1)

2

2

2

2

Then CO is converted to CO

2

and H

2

by reacting CO with water vapor through a shift reaction (water-gas shift reaction):

CO HCOH

+

Ο

�

+

(21.2)

2

2

2

At this stage, the gas is composed mainly of CO

2

and H

2

. The concentration of CO

2

is about 15-60% (dry basis) and the total

pressure is typically between 2 and 7 mpa. CO

2

is removed by an absorption process. The typical solvents used for precombustion

capture are either physical (i.e., Selexol [18] and Rectisol) or chemical (i.e., methyldiethanolamine [19]). Unlike the solvents

for postcombustion capture, these technologies are mature and proven on a large commercial scale [20].

Although the initial fuel conversion steps of precombustion are costlier and more elaborate, the higher concentrations and

higher pressure of CO

2

in the gas stream make the separation and the subsequent compression of CO

2

easier than in postcom-

bustion. The removal rate of CO

2

is over 90%. In precombustion technology, the energy required for water-gas shift reaction,

solvent regeneration, and compression of CO

2

could represent anywhere from 14 to 25% of the output in a natural gas combined

cycle (NGCC) [21].

21.2.3.2 Postcombustion Capture

In this method, CO

2

is captured in a scrubber from flue gases that are close to atmospheric

pressure using an absorption process based on chemical solvents, such as amines (e.g., monoethanolamine). This is because

chemical solvents are less dependent on partial pressure than physical solvents, and the partial pressure of CO

2

in the flue gas

is low, typically 4-14% by volume. The gases pass through the absorption column where the solvent reacts with the CO

2

, chemically