Environmental Engineering Reference

In-Depth Information

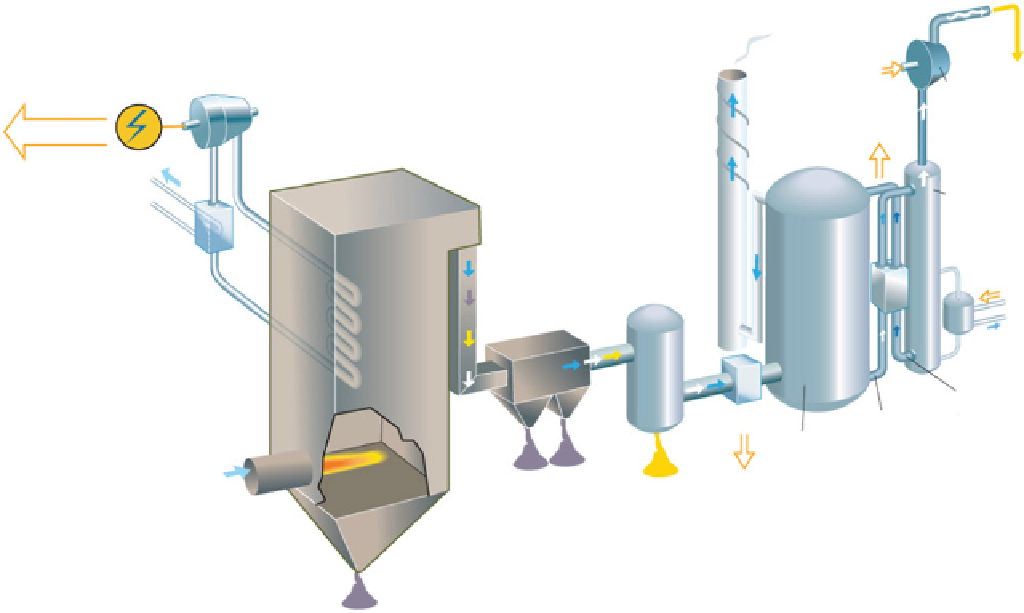

Postcombustion capture (absorption process)

CO

2

Mechanical

energy

Low-

temperature

heat

Clean

flue gas

Steam turbine

CO

2

compressor

Electricity

Boiler

Cooling water

CO

2

stripper

Steam

condenser

Sulfur

removal

Particle

removal

Heat

CO

2

-lean

absorbent

Cooler

CO

2

-rich

absorbent

CO

2

absorbent

Air

fuel

Low-

temperature

heat

Fly ash

Gypsum

Bottom ash

fiGure 21.9

postcombustion schematic diagram flow. Courtesy from Ref. [22].

binding it and removing it from the gas stream. After absorption, the cleaned flue gases primarily contain water vapor and

climatic inactive nitrogen (see Fig. 21.9). On leaving the scrubber, the solvent is heated to release the nearly pure CO

2

and the

solvent can then be reused (Fig. 21.10). Heat from the power plant's steam turbines is used to raise the temperature to the

desired level. The captured CO

2

can be transported to a storage site.

In the case of a power plant using postcombustion capture, the energy required for solvent regeneration and CO

2

compres-

sion could represent anywhere from 25 to 35% of its output.

21.2.3.3 Oxyfuel Combustion Capture

Oxyfuel combustion is still in the demonstration phase and uses high-purity

oxygen. This results in relatively higher CO

2

concentrations in the gas stream and, hence, in easier separation of CO

2

but

at the cost of increased energy requirements for the separation of oxygen from air. A large amount of oxygen is required

for combustion, which is obtained from an air separation unit. The flue gas from oxycombustion is compressed and

chilled to separate out nitrogen, oxygen, and other impurities. The resulting CO

2

concentration is typically 95 mol% or

more (Fig. 21.11).

21.3

Novel teChNoloGies

A major challenge in the implementation of carbon capture and storage (CCS) is that current industrial carbon capture

technologies are energy-intensive and not cost-effective [24]. To be viable, a capture technology must achieve 90% CO

2

capture with a maximum energy penalty of 10% [25]. The conventional technologies have many disadvantages: the

liquid-gas interaction, that is, the aqueous amine solutions, requires huge capital and operational costs because of the

energy needed for regeneration. Recently, gas-solid adsorption processes have been proposed as promising technologies

for carbon capture [26]. Solid sorbents have the potential to reduce the energy demand of capture processes because of

their potentially higher loading capacities, the absence of solvent heating and vaporization during regeneration, lower

material heat capacities, and lower heat of sorption [27-29]. These materials require a large surface area-to-mass ratio