Environmental Engineering Reference

In-Depth Information

(a)

(b)

(d)

(f )

(h)

AgNW/CNT

CNT only

100

Ag

Cotton

Ws CNTs

80

60

40

20

Live cells

(c)

(e)

(g)

200 nm

0

-20

-10

0

10

20

1 mm

10 µm

Dead cells

Voltage (V)

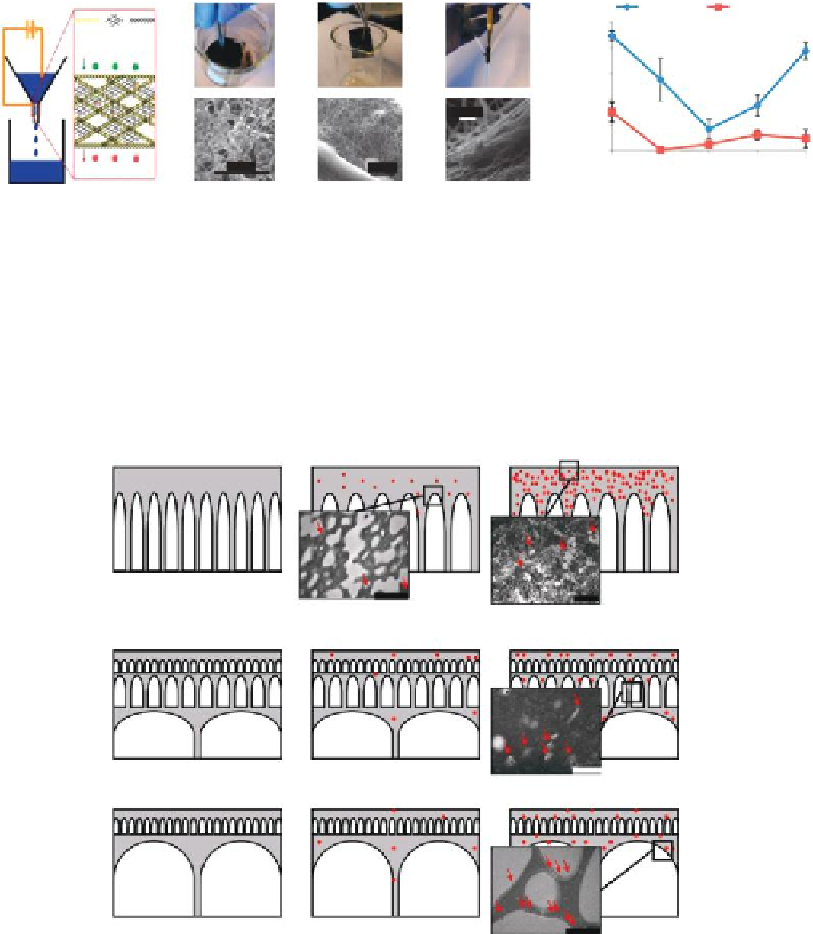

FIGURE 12.13

Schematic, fabrication, and structure of cotton, AgNW/CNT device. (a) Schematic of proposed active mem-

brane device. (b) Treatment of cotton with CNTs. (c) Treatment of device with silver nanowires (AgNWs).

(d) Integration of treated cotton into funnel. (e) SEM image showing large-scale structure of cotton ibers.

(f) SEM image showing AgNWs. (g) SEM image showing CNTs on cotton ibers. (h) Inactivation eficiency at

ive biases for AgNW/CNT cotton as well as CNT-only cotton. (From Schoen, D.T. et al.,

Nano Lett.

, 10, 3628, 2010.

With permission.)

PSf/Ag

in

type I

PSf/Ag

ex

type I

PSf type I

1 µm

2 µm

PSf/Ag

in

type II

PSf/Ag

ex

type II

PSf type II

400 nm

PSf/Ag

in

type III

PSf/Ag

ex

type III

PSf type III

1 µm

FIGURE 13.1

Example of nanomaterials that could be afixed to a membrane surface. (From Figure 5.1 in Chapter 5,

Multifunctional Nanomaterial-Enabled Membranes for Water Treatment, pp. 59-75, by Tarabara, V.V. Reprinted

from

Nanotechnology Applications for Clean Water

, Diallo, M.; Duncan, J.; Savage, N.; Street, A.; Sustich, R., editors,

Elsevier Ltd., Kidlington, UK (2009). Reprinted with permission of Elsevier.)