Civil Engineering Reference

In-Depth Information

Steel beam

Reinforcement bar

Concrete

Headed stud

Profiled steel sheeting

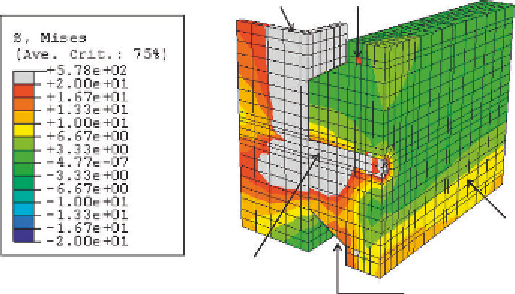

Figure 5.36 Stress contours at failure for pushout specimen tested in [2.58, 2.59] and

modeled in [2.71].

the concrete are in the regions around the stud forming a conical shape. This

conical failure mode of concrete was explained in detail both experimentally

and numerically by Ellobody [2.68-2.70] for the investigation of pushout

tests with solid slabs and precast hollow-core slabs. The conical concrete fail-

ure is also known as concrete pullout failure since the tensile force acting on

the stud forces the slab to move up and leave a cone of concrete around the

stud. The concrete conical failure (or concrete pullout) was also observed

experimentally and discussed theoretically in the previous studies on pushout

tests with profiled steel sheeting conducted in [2.57-2.59]. The concrete

conical failure occurred, and the stud reached its yield stress near the collar.

Figure 5.37

showed the deformed shape obtained from the finite element

analysis for the 13

65 mm headed stud shear connector tested in [2.58,

2.59] and modeled in [2.71]. The verified finite element models [2.71] were

used to performextensive parametric studies. The finite element strengthswere

compared with design strengths calculated using current codes of practice.

The aforementioned finite element modeling of shear connection can

provide a good insight into the local behavior of headed shear studs in the

connection. However, to model a full-scale composite girder having many

shear studs, we can benefit now from the special-purpose elements pro-

videdinABAQUS[1.29]elementlibrary.Theshearconnectorscanbe

modeled using a nonlinear spring element (using SPRING option). The

spring element is of zero length that bears only shear force and obeys

the load-slip characteristic of the shear connector used. The positions of

Search WWH ::

Custom Search