Civil Engineering Reference

In-Depth Information

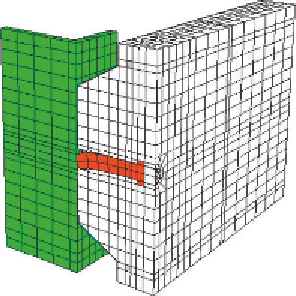

Steel beam

Headed stud

Concrete

Profiled steel sheeting

Reinforcement bar

Figure 5.37 Deformed shape at failure for pushout specimen tested in [2.58, 2.59]

and modeled in [2.71].

the spring elements coincide with the positions of the shear connectors

used in the composite beam. Because the load-slip characteristic of the

shear connector is nonlinear, the force is assumed to be a function of rel-

ative displacement in the spring and is defined by giving a table of force

values in ascending values of relative displacement. The load-slip charac-

teristic of the shear connector is obtained from the corresponding finite

element modeling of the local shear connection. It should be noted that,

for a given composite beam, loading, and design method, complete shear

interaction is defined as the least number of the connectors such that the

bending resistance of the beam would not be increased if more connectors

were provided. Partial shear interaction is assumed when the number of

connectors used in the composite beam is less than the number of shear

connectors that cause full shear interaction. In the design with complete

shear connection, it is normally assumed that the failure of shear con-

nectors does not occur and the influence of connector deformation on

the structural behavior was neglected. With partial shear connection,

the ultimate resistance of the beam depends on the ultimate resistance

of the shear connector and its ductility. In these cases, it is important

to use the correct load-slip behavior of the connector since it can cause

significant redistribution of stresses between the connectors in both

serviceability and ultimate limit states.

Search WWH ::

Custom Search