Information Technology Reference

In-Depth Information

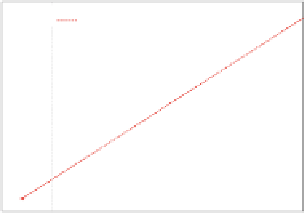

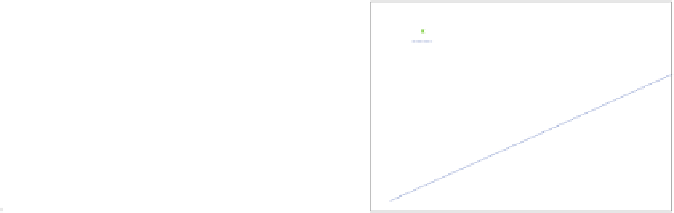

Energy Components Comparison (Terf 3x3)

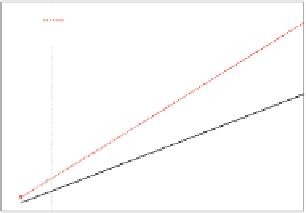

Total Energy Comparison

180000

300000

Magnets

Capacitance

Terf 3x3

Terf 5x3

Ni 3x3

Ni 5x3

160000

250000

140000

120000

200000

100000

150000

80000

60000

100000

40000

50000

20000

0

0

0

100

200

300

400

500

600

0

100

200

300

400

500

600

PZT thickness (nm)

PZT thickness (nm)

(a)

(b)

Fig. 16.

(a) Comparison between energy consumption components for a 3

×

3

NAND/NOR with magnet of Terfenol. Energy required to reset the magnets is con-

stant and much lower than energy lost to charge the capacitor. (b) Comparison between

NAND/NOR with different sizes and different materials. Nickel has an overall lower

energy consumption due to a higher Young modulus.

against 1400

Kb

T

with a PZT thickness of 40 nm). To be fair also the losses due

to Joule effect should be considered, however, since piezoelectric materials are

insulators, the value of current is so small that the resulting losses are 7-8 orders

of magnitude smaller than the energy required to charge the capacitance, that is

the only really important source of energy loss. Moreover, the distance between

electrodes is quite big so no relevant tunnel current can be expected.

Figure

16

(b) shows instead a comparison between the total energy consump-

tion with gates of different sizes, 3

5 (that means an height of 3

magnets and a width of 5 magnets), and considering both terfenol and nickel

as magnetic materials. As can be clearly observed gates with a width of 5 mag-

nets have a bigger energy consumption than gates with a width of 3 magnets.

This is expected because with a bigger width the capacitance is smaller while

the voltage is bigger. From Eq.

14

it is evident that voltage has a bigger impact

compared to the capacitance, so reducing the capacitance and increasing the

voltage overall increases the energy consumption. What is partially unexpected

is that, changing the magnetic material employed changes the total energy con-

sumption. As can be seen from Fig.

16

(b), using Nickel leads to a lower energy

consumption. This can be explained looking at Eq.

13

. Nickel magnets require

a bigger stress, nonetheless their Young modulus is also bigger, so overall the

required voltage and the energy consumption are lower. While Nickel shows a

reduced power consumption, Terfenol remains the privileged choice for its better

tolerance to process variations.

PZT thickness is an important parameter that must be chosen carefully

considering both energy consumption requirements and technology limitations.

With magnets 10 nm thick the minimum thickness for the PZT substrate is

40 nm. The PZT must be much thicker than the magnets to be sure that the

mechanical stress is completely transferred from the substrate to the magnets.

×

3 and 3

×

Search WWH ::

Custom Search