Environmental Engineering Reference

In-Depth Information

Table 12

The performances in the large-scale device fabricated by the lamination process

Jsc (A/cm

2

)

Rs (X cm

2

)

p(X cm

2

)

Voc (V)

FF (%)

PCE (%)

Non

3.62

0.73

37.59

0.99

93.26

516.62

100 C, 5 min

6.58

0.71

44.94

1.50

34.53

506.63

100 C, 10 min

7.04

0.69

46.71

2.27

21.59

371.70

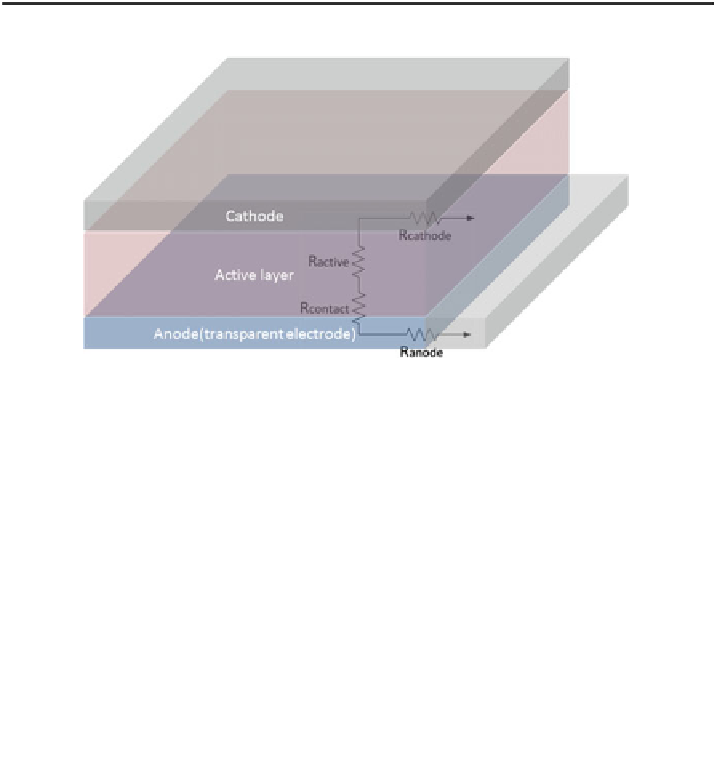

Fig. 29

Description of series resistance components inside conventional OPV cells

electrode. R

active

and R

contacts

does not increase with area scaling since they are

vertical components in the cell which have the same carrier travel distance

regardless of cell area. Furthermore, the metal cathode has negligible series

resistance compared to transparent anode electrode such as ITO, with typical

conductivity ratio of *100:1 [

18

]. Therefore, the main factor that determines the

resistive loss with increasing device size is the resistance of transparent electrode.

Figure

29

shows each component inside the cell graphically.

The effect of the series resistance can be studied in more detail with the non-

ideal equivalent circuit model, which is widely acceptable for both inorganic solar

cells and organic solar cells [

19

]. With the parasitic resistances included, the diode

equation becomes

þ

V

J

ðÞ

R

S

A

R

sh

A

ð

Þ

qV

J

ðÞ

R

S

A

J

ðÞ

¼J

0

e

1

J

ph

;

ð

17

Þ

nkT

where J

0

is the reverse saturation current, V is the applied voltage, J is the current

density of the cell, n is the diode ideality factor, k is Boltzmann's constant, T is

temperature, R

S

is series resistance, R

sh

is shunt resistance and J

ph

is the photo-

current generated by the cell. The parameters J

0

, n, R

S

, R

sh,

and J

ph

can be obtained

by fitting the diode model to the experimental J-V data from actual OPV devices

under illuminated and dark conditions. Servaites et al. [

20

] showed the impact of

R

S

on the performance of large area P3HT:PCBM BHJ OPVs using ITO anode.

Search WWH ::

Custom Search