Environmental Engineering Reference

In-Depth Information

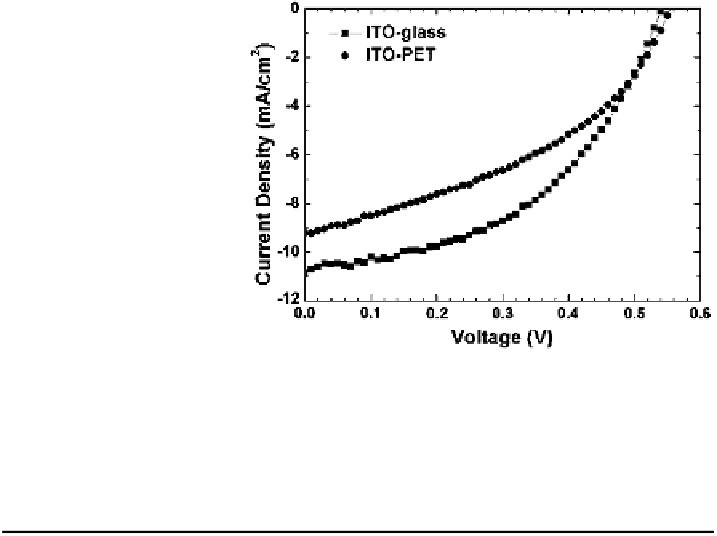

Fig. 28 The device

performance of the laminated

devices using ITO-glass and

ITO-PET

Table 11

The device performances fabricated by the lamination process

Jsc (mA/cm

2

)

Device

Voc (V)

FF (%)

PCE (%)

ITO-PET

9.21

0.56

40.95

2.11

ITO-glass

10.87

0.55

46.1

2.76

2.5.6 Influence of Series Resistance in Large Area Solar Cells

We have already seen the impact of series resistance in large area device to the

achievable OPV efficiency. Practical large area solar cell devices suffer more from

resistive losses, which should be minimized to maintain the performance of the

devices. We will quantify the effect of series resistance, R

S

by computing the

resistive power loss. In small area devices, organic semiconducting active layers

contribute more to the resistive power loss than other factors. However, as the size of

the devices increases, the R

S

of the transparent electrodes become the main factor of

the resistive loss [

17

]. The total resistive power loss per unit area is given by

Þ

2

P

R

¼

R

S

J

max

A

ð

¼ R

S

AJ

max

;

ð

15

Þ

A

where P

R

is the total resistive power loss per unit area, R

S

is the series resistance in

the device, J

max

the current density, and A the area of the devices. R

S

in organic

solar cell contains the resistances of the anode, active layer, contacts, and cathode:

R

S

¼

R

anode

þ

R

active

þ

R

contacts

þ

R

cathode

;

ð

16

Þ

where R

active

and R

contacts

are the series resistances of active layer and contacts of

each layer, respectively. When we assume the conventional structure of organic

solar cell, cathode side is the reflective metal and the anode side is the transparent

Search WWH ::

Custom Search