Environmental Engineering Reference

In-Depth Information

(a)

(b)

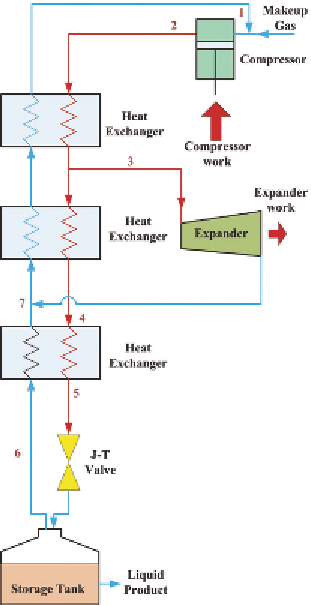

FIGURE 5.9

Schematic and temperature-entropy diagram of a simple Claude cycle. Reproduced with

permission from Barron [11]. (See color insert.)

thermal convection, and thermal conduction have to be taken into account in

designing the vessels (Fig. 5.10). The inner vessel is insulated with a multi-

layered material with spacers acting as thermal barriers. The spacers are

coated with high reflective Ag films to minimize thermal radiation loss. This

inner vessel is mounted within the outer vessel by means of specially designed

internal fixtures. The volume between the inner and outer vessels is evacu-

ated to high vacuum to avoid possible heat leaks by thermal convection. In

spite of the insulation, due to the unavoidable heat input, hydrogen will

evaporate in the tank, which will cause the pressure rise in the vessel. Pres-

sure build-up can be treated to be linearly proportional to storage time. Once

the pressure reaches the maximum operation pressure of the tank, a blow-off

valve has to be opened to release the hydrogen in order to maintain the safety

of the system. The unexpected heat input could come externally or internally.

As discussed in Chapter 1, hydrogen has two forms, the parahydrogen and

orthohydrogen. These two forms of hydrogen not only have different internal

Search WWH ::

Custom Search