Environmental Engineering Reference

In-Depth Information

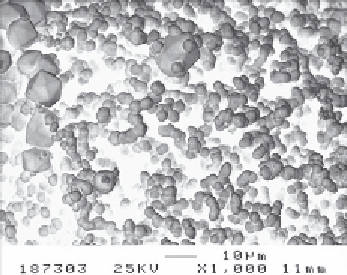

FIGURE 10.8

SEM images show different morphologies of Mo metals obtained from hydrogen reduc-

tion under (left) low and (right) high moisture content.

Source

: Reproduced with permission from Schul-

meyer [17].

As another example, molybdenum metal powder is produced industrially

by reducing high purity molybdenum compounds such as molybdenum tri-

oxide (MoO

3

, grey-green powder), ammonium hexamolybdate ((NH

4

)

2

Mo

6

O

19

,

yellow powder) and ammonium dimolybdate ((NH

4

)

2

Mo

2

O

7

, white powder),

with hydrogen gas [15]. The mechanism of reduction consists of two stages

[17]. The first stage involves a reaction from MoO

3

to MoO

2

via chemical

vapor transport process. In the second stage, MoO

2

is further reduced to

metal Mo:

MoO

+

2

H

→ +

Mo

2

H O

.

(10.9)

2

2

2

Different grain sizes and shapes of metal molybdenum can be obtained

by adjusting moisture content of H

2

at entry (Fig. 10.8).

10.5 HYDROGEN UTILIZATION IN MANUFACTURING PROCESSES

10.5.1 Welding Gas: Oxy-Hydrogen Welding

Hydrogen has been used for welding as early as the beginning of the last

century [18]. Hydrogen reacts with oxygen in a flame to form water, and

simultaneously produces enormous energy for the welding process:

−

1

2

H

+ →

O

2

H O H

;

∆

=−

572

kJ mol

⋅

.

(10.10)

2

2

2

Search WWH ::

Custom Search