Environmental Engineering Reference

In-Depth Information

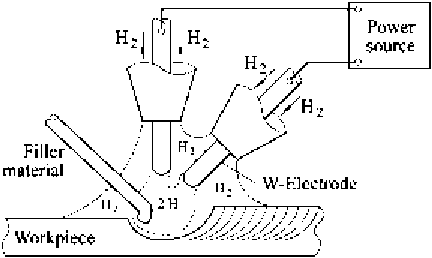

FIGURE 10.9

Schematic diagram illustrating the device for arc-atom welding.

Source

: Reproduced

with permission from Suban et al. [18].

Before the introduction of acetylene, hydrogen was the basic combustible

component in this kind of welding. Moreover, hydrogen gas has also been

used for arc-atom welding (Fig. 10.9) [18].

As shown in Figure 10.9, an alternating arc is maintained between two

tungsten electrodes, with hydrogen fed into the arc. When hydrogen is passed

through the electric arc, the temperature in the arc core is sufficiently high

to initiate dissociation of hydrogen gas to form atomic hydrogen:

−

1

H

← →

+

H H H

;

∆

=−

422

kJ mol

⋅

.

(10.11)

2

→

The energy required to break down the H-H covalent bond is provided

by the arc. When the hydrogen atoms are recombined, they give the energy

back and the flame at this point can reach as high as 3700°C and can thereby

be used for welding. This process has been widely used for manual and

automatic welding of metal sheets.

Recently, Tusek et al. has found that the static characteristic of the welding

arc can be changed by adding different amounts of hydrogen in argon gas.

The energy of the arc and the thermal and melting efficiency can be enhanced

as a result of mixing hydrogen and other gases with different physical and

chemical properties (e.g., thermoconductivity, enthalpy, and electric conduc-

tivity) [19].

10.5.2 Coolant

The thermal conductivity of hydrogen is substantially higher than that of

other gases (Fig. 10.10). Moreover, it has high specific heat capacity, low

Search WWH ::

Custom Search