Biomedical Engineering Reference

In-Depth Information

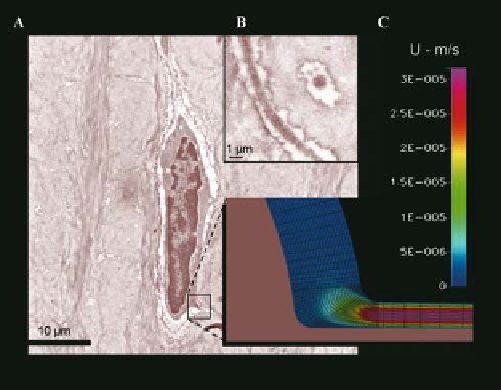

Figure 10.12.

Transmitted electron micrographs

of an osteocyte. Osteocyte (A) with inset showing

osteocyte process in the plane and perpendicular

to the plane of the micrograph, respectively; a

computational fluid dynamics model of a portion

of the osteocyte and its process predicts the fluid

velocity magnitudes within the pericellular space.

Reprinted from

,

Volume 33, E. J.Anderson, S. Kaliyamoorthy, J. I. D.

Alexander, and M. L. Knothe Tate, “Nano-microscale

models of periosteocytic flow show differences in

stresses imparted to cell body and processes,” p. 54

and cover image, 2005, with permission from

Springer.

Annals of Biomedical Engineering

10.9 Design Approaches:

The Tissue Engineer's

Computational Toolbox

Antonio Mikos. The scaffold is a prototype

developed with stereolithography and made of

poly(propylene fumarate) (PPF), a photopoly-

merizable, biodegradable resin. The scaffold is

a three-dimensional, layered cylinder with nine

circular and four semicircular channels in the

longitudinal direction (Fig.

A and B); all

channels are connected through seven trans-

verse rectangular channels. Scaffold geometries

are created using a solid modeling program

(Pro/Engineer, PTC) and then fabricated from

poly(propylene fumarate), PPF, with the aid of

a stereolithographic, rapid prototyping machine

(Viper si

10

.

13

The previous sections addressed variations in

length scale as they affect model building at the

level of the whole organ, the tissue, the cell, and

the molecule. Also discussed was whether to

approximate the system as a

continuum

or to

consider its structure

discrete

(Table

).

Although progress has been made in the fi eld

of tissue engineering, signifi cant challenges

remain in the regeneration and repair of bone,

a tissue that serves mostly structural and

mechanical functions. A major stumbling block

has been the lack of understanding of the mech-

anisms of transport to and between bone cells.

The importance of fl uid fl ow for the promotion

of cell viability and tissue health has been

described [

1

TM

,

2

3

D Systems, Valencia, CA). By

using

CT imaging methods (Scanco, Bassers-

dorf, Switzerland), actual geometries for the

prototypes (Fig.

µ

B) can be compared with

the target geometries. To predict fl ow through

the target design scaffold and through actual

rapid prototyped scaffolds, computational fl uid

dynamics methods were applied analogous to

those outlined in the previous section.

First, a fl uid mesh is created and fl uid fl ow is

calculated by using a CFD software package

(CFD-ACE, CFDRC, Huntsville, AL). In these

studies, we fi rst estimate the effects of noncon-

formance with specifi cations, i.e., the variance

between the target and the actual geometries, by

reducing iteratively (from

10

.

13

] in the earlier portions of this

chapter. The following case study illustrates one

example in which computational modeling can

be used to optimize engineered tissue design.

14

,

16

10.10 Case Study:

Design Optimization of a

Tissue-Engineering Scaffold

%

increments) the through-channel diameters in

the scaffold. Flow is induced by a pressure gradi-

ent for a fl uid medium idealized as water (density

=

1000

0

% to

100

% in

25

kg/m

3

, viscosity

kg/ms). On the

basis of the mass fl ow rate calculated through

the fl uid mesh of each computational scaffold,

permeability is determined by Darcy's law,

=

0

.

001

The case study has used a scaffold designed

by Dr. Lorna Gibson (MIT) and kindly provided

by Dr. David Dean, in collaboration with Dr.