Biomedical Engineering Reference

In-Depth Information

The distance between the end of the barrel and the surface of the substrate

was 3.0 inches for all impacts. Once impacted with the substrate, the impact

specimens were cut from the surrounding material, and then mounted for

further examination. Impacts were recorded with a high speed camera, model

Fastcam Ultima 1024 from Itronx Imaging Technologies. Figure 58 shows the

casing, filled with aluminum powder, impacting the aluminum substrate. The

bright spots in the figure are the particles reflecting light, and the black image

impacting the surface is the delrin casing disintegrating. Figure 59 shows

particles clearly striking the substrate before the delrin casing appears in the

frame. This is evidence of air loss occurring in the barrel, and also evidence of

loose particles inside the barrel.

The mounted impact specimens, two steel and two aluminum substrates,

were examined under the light microscope. Each specimen was examined with

various magnifications and in different locations in an attempt to find if

particles form a permanent bond with the substrate. It appears from several

images, after polishing to remove loose particles, that a small number of

particles are bonded to the surface in the case of sample 1, where the fine

aluminum particles were impacted onto the aluminum substrate. Images from

samples 2, 3, and 4 show evidence of erosion, where particles have not bonded

to the substrate. Figure 60 shows images of sample 1 before the impact (bare

substrate) and after the impact with polishing already performed.

Reproduced with permission. Copyright retained by Inderscience Publishers.

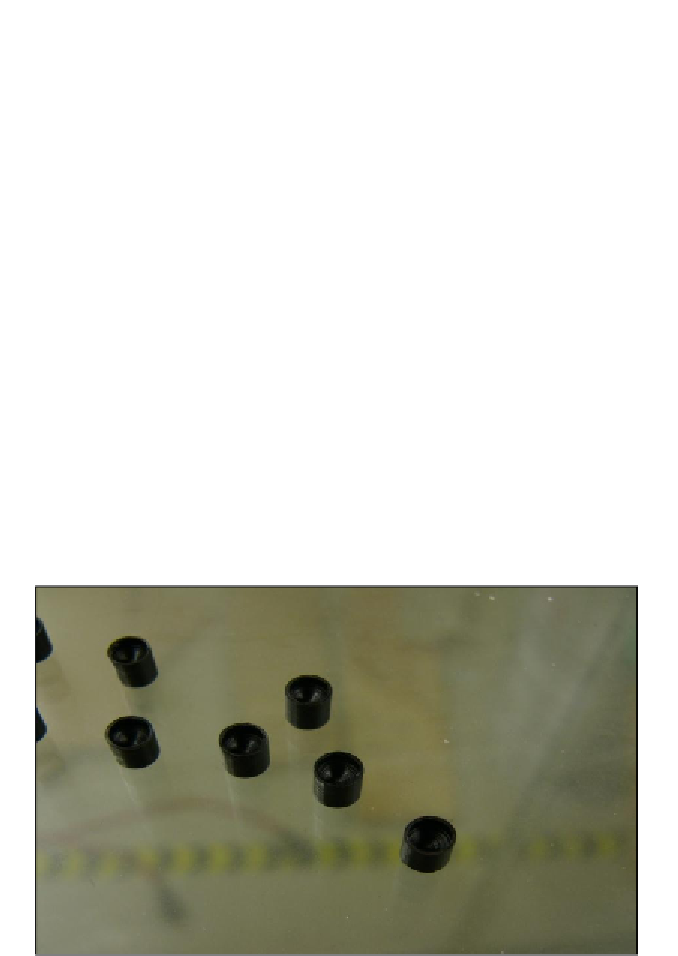

Figure 57. Delrin Casings for Powder Delivery.