Agriculture Reference

In-Depth Information

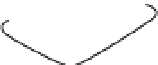

Cooking chemistry: action of

sodium hydroxide on lignin

M : middle lamella

P : primary wall

SI : external secondary wall

S2 : central secondary wall

S3 : internal secondary wall

L : Lumen

L

When the temperature reaches 140°C in

strong alkaline conditions, the OH groups

located in

S3

position of the aromatic cores

are partially ionized. A nucleophilic attack

of the

α

S2

carbons generates phenolic frag-

ments. The lignin is then divided into

small soluble units of phenolic type

(Fig. 13.7).

The action of the sodium sulfide as a buffer

helps to maintain a high alkaline medium, but

secondary reactions of degradation are induced

by HS

−

(generated from Na

2

S) reducing the

size of lignin fragments. HS

−

is responsible for

the demethylation of aromatic groups generat-

ing methylmercaptan, MeSH, with a character-

istic smell.

The demethyled groups are then trans-

formed into quinines, leading to the brown col-

oration of the kraft pulp (Fig. 13.8).

Hemp bast fibre cooking yields are around

65-75%, depending on the quality of the deco-

rticated hemp. The resulting pulp is brown and

must be bleached for paper use.

β

S1

P

M

Fig. 13.6.

Fibre macrostructure.

13.4 Pulping Processes

The pulping processes used with hemp are

based on the application of chemicals. Four

main processes can be employed:

•

Kraft process

•

Soda or soda anthraquinone process

•

Neutral sulfite process

•

Acidic sulfite process.

13.4.2 Soda or soda

anthraquinone process

13.4.1 Kraft process

This is the worldwide chemical pulp manu-

facturing process most used for lignocellu-

losic materials. The cooking action is done

at high temperature (150-170°C) using a

mixture of caustic soda (NaOH) and sodium

sulfide (Na

2

S). The sodium sulfide is neces-

sary as a buffer and to prevent cellulose oxi-

dation, because of its reductive properties.

One advantage of the kraft process is the

possibility of recovering all the chemicals by

evaporation and combustion of the residual

liquors, leading to self-sufficiency of the mill in

terms of energy.

The cooking conditions are usually:

1. 15-18% NaOH and 4-6% Na

2

S based on

the dry raw material weight.

2. The chemicals are dissolved in water; the

liquor is 4 or 5 times the raw material weight.

3. A temperature of 170-175°C is maintained

for 1-3 h.

This process is similar to the kraft process,

using strong alkali charges, leading to the

same reactions as described previously.

Anthraquinone is used in place of sodium

sulfide, in this case to prevent the peeling

reaction responsible for the depolymeriza-

tion of the cellulose. During cooking, some

hemicelluloses are also protected and kept in

the pulp.

Anthraquinone is used in small charges as

a catalyst (0.05-0.1%).

This type of cooking leads to slightly

higher yields (1-3%). The unbleached pulp is

quite similar to the kraft pulp.

13.4.3

Neutral sulfite process

The neutral sulfite process uses the principle

of sulfonation of the lignin using sodium sulfite